Steel beam and steel plate concrete combination shear wall connecting joint and construction method thereof

A combination of shear wall and steel plate concrete technology, which is applied in the direction of architecture and building structure, can solve the problems of exposed structure, occupying space, and affecting the appearance, so as to avoid brittle fracture and reduce stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

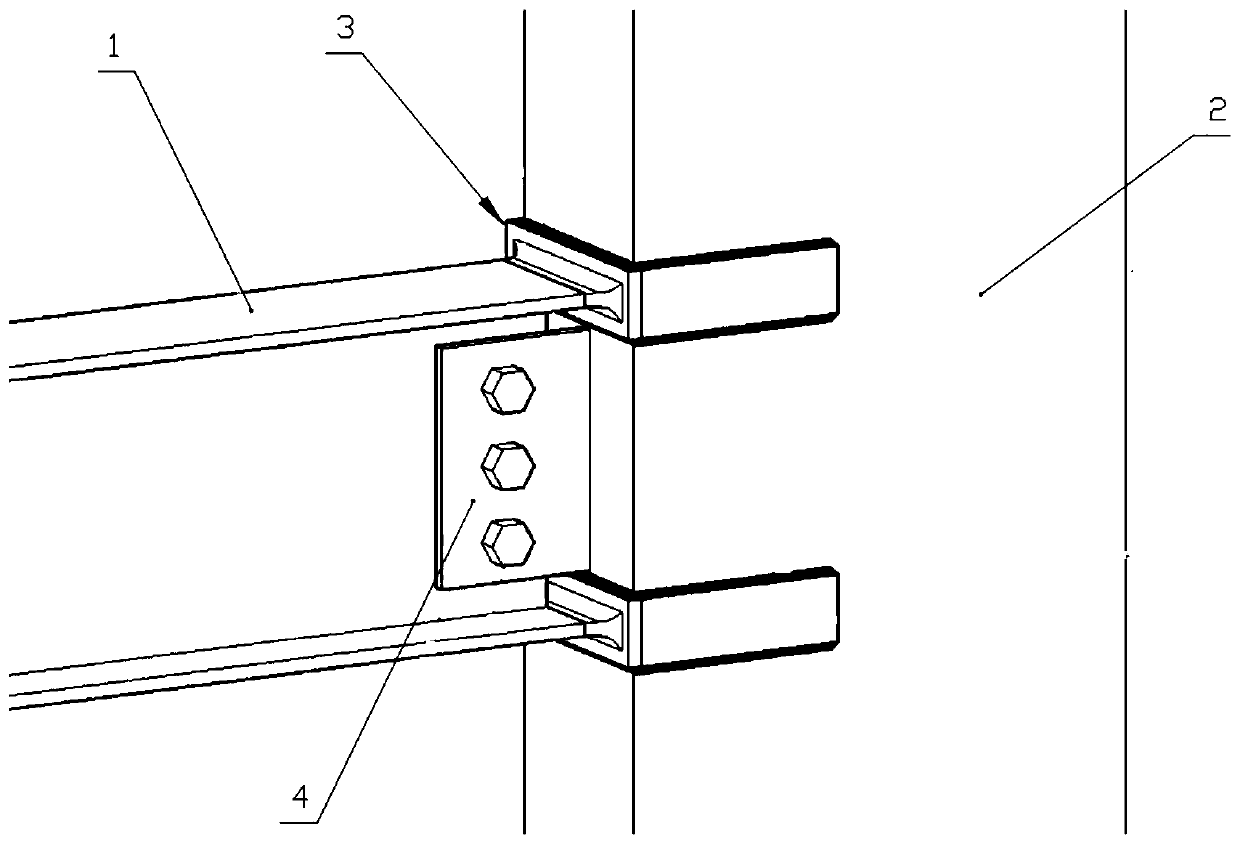

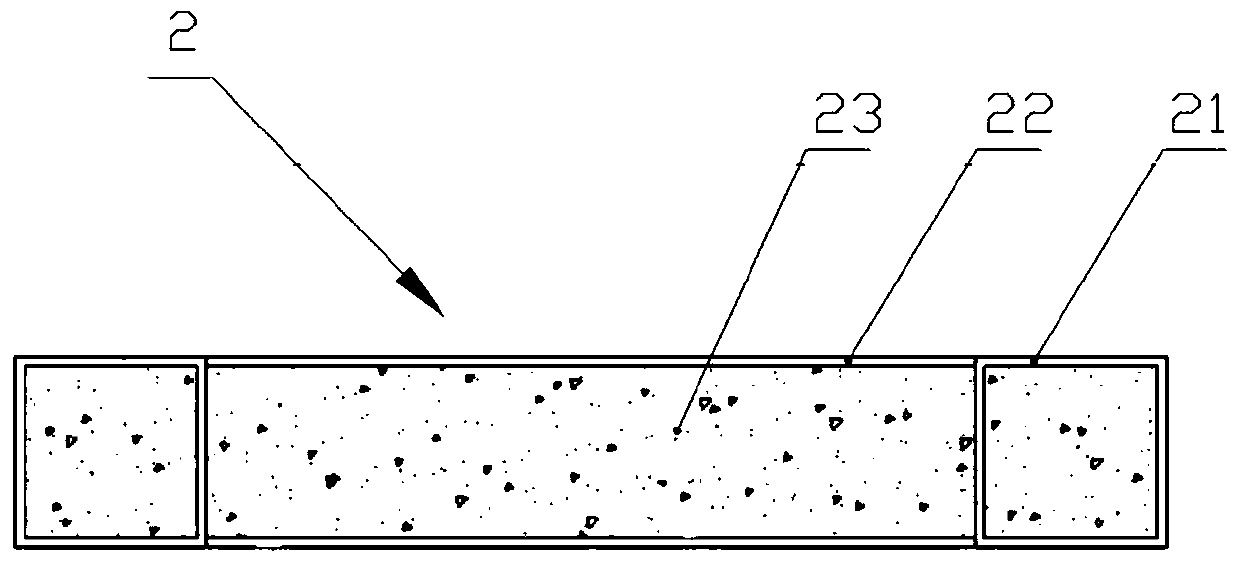

[0040] Preferred embodiment one, such as figure 1 As shown, the connection node disclosed in this embodiment is used for the assembly of the steel beam 1 and the steel plate concrete composite shear wall 2 . The connection node is composed of a pair of split steel connectors 3 and a shear plate 4 . Wherein the steel beam 1 is an I-shaped steel beam, and an installation hole is opened on its web. Such as figure 2 As shown, the steel plate concrete composite shear wall 2 includes an end column 21, an outer steel plate 22 and concrete 23, a pair of outer steel plates are connected between the two ends to form a filling cavity, and concrete is filled in the filling cavity and the inner cavity of the end column.

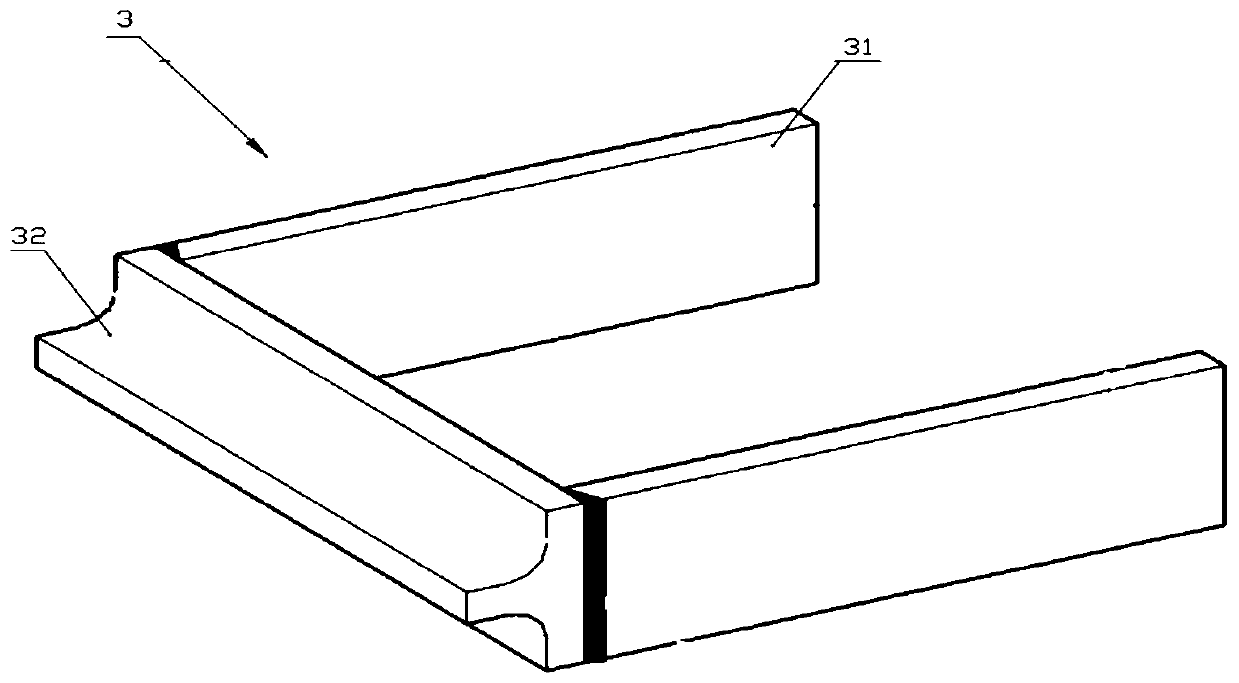

[0041] Such as image 3 As shown, the split steel connector 3 includes a T-shaped piece 31 and a side plate 32 . The width of the head of the T-shaped piece is slightly larger than the thickness of the shear wall 2, so that a pair of side panels are welded to the hea...

Embodiment 2

[0053] Preferred embodiment two, such as Figure 5 As shown, the connection node disclosed in this embodiment is used for detachable assembly of the steel beam 1 and the steel plate concrete composite shear wall 2 .

[0054] The difference between this embodiment and the preferred embodiment 1 is that the mounting holes are processed on the flange of the horizontal steel beam, the mounting holes are processed on the rod of the split steel connector, and the rod of the split steel connector is attached to the horizontal steel beam. The bolts passing through the connecting holes and the mounting holes are locked on the flanges with corresponding nuts.

[0055] In comparison, the benefits of the present invention are:

[0056] 1. When put into use, the split steel connector part is used as the connector between the horizontal steel beam and the end of the shear wall, and the transition area is a circular arc section, which can effectively reduce the force transmission between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com