Belleville spring assembly detection device

A disc spring, assembly detection technology, applied in measuring devices, optical devices, instruments and other directions Inverse and other problems, to achieve the effect of high accuracy, low cost, and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

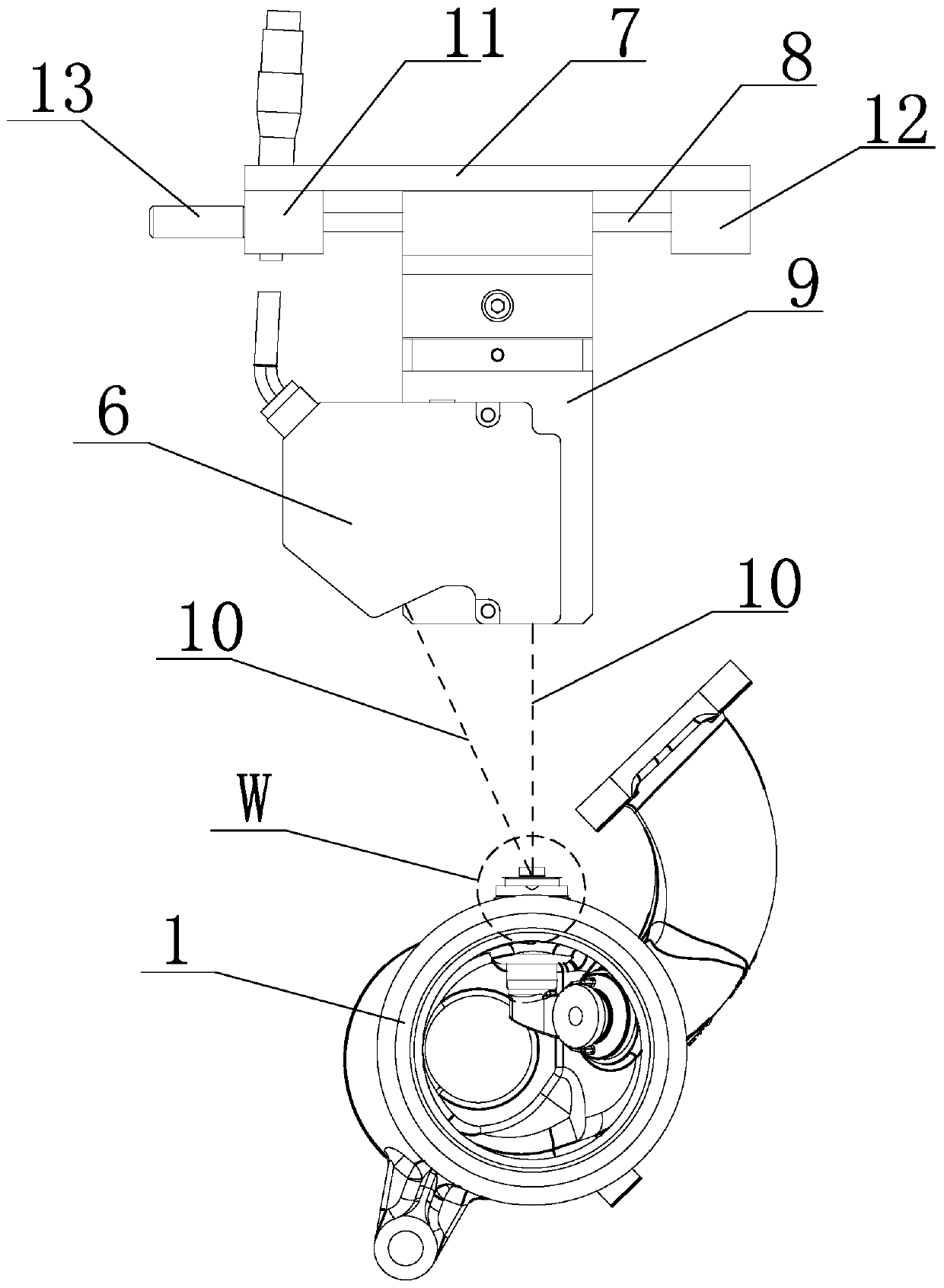

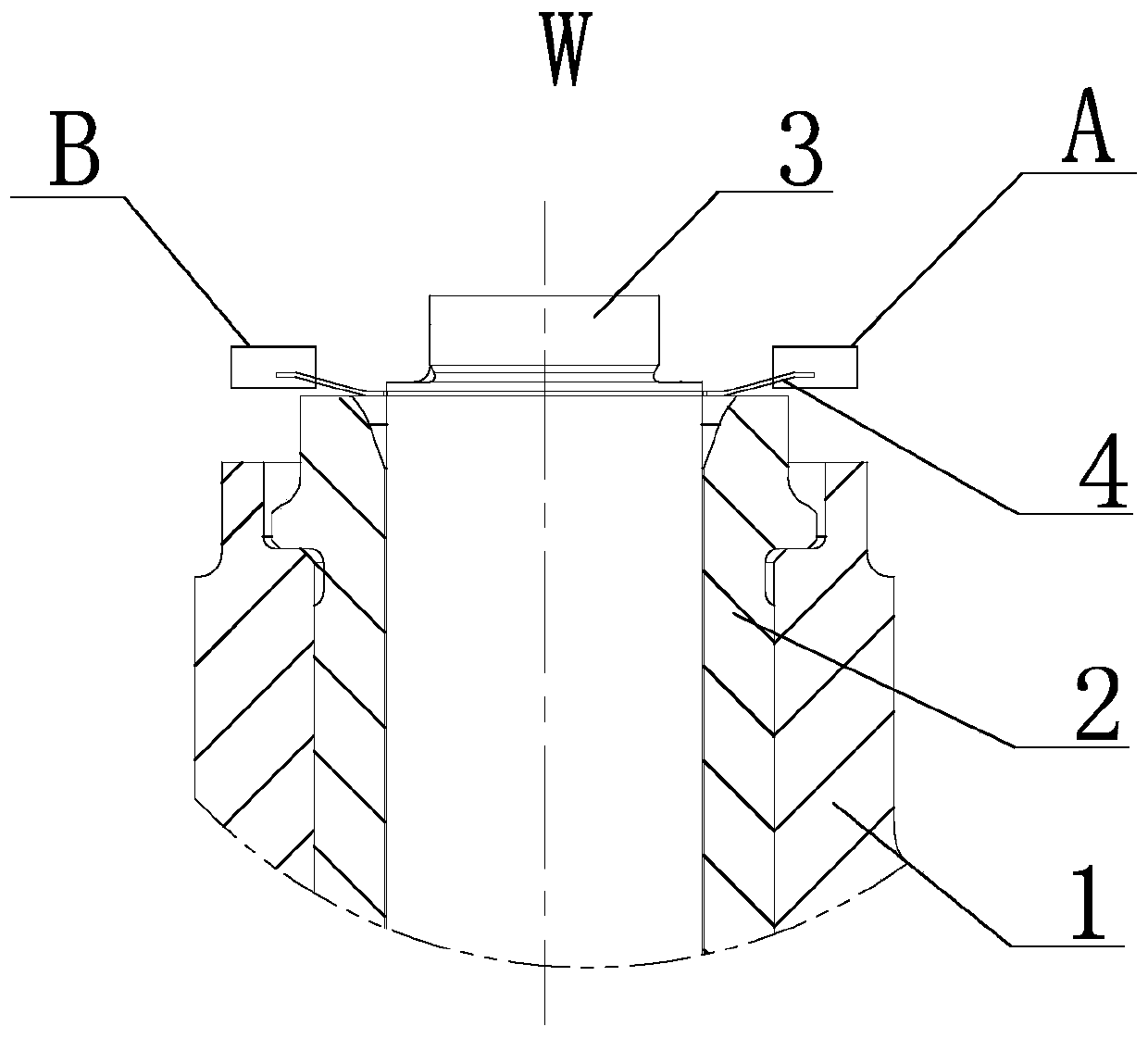

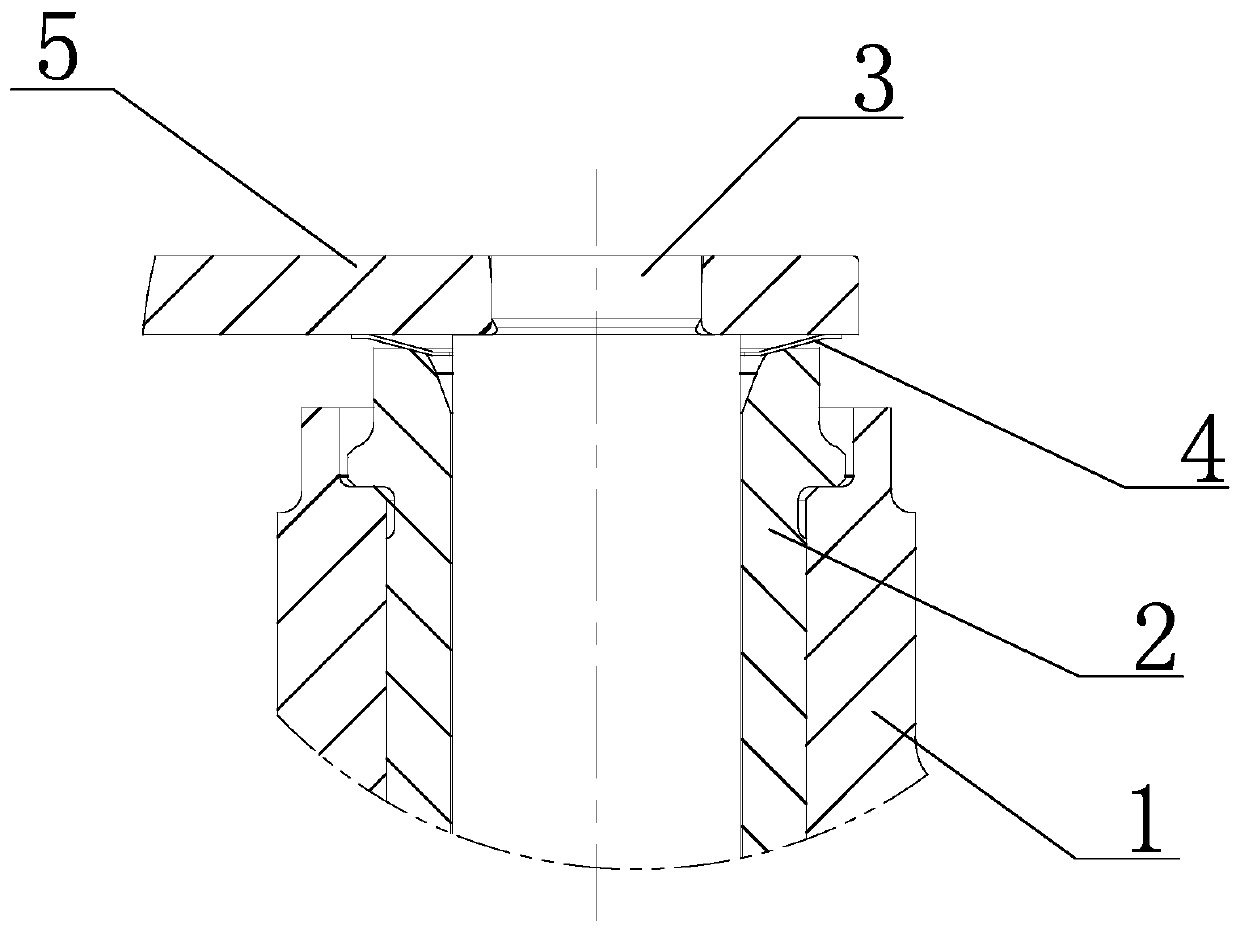

[0026] to combine Figure 1-Figure 3 As shown, a disc spring assembly detection device includes a laser profiler 6, a fixed bracket 7, a boom 9, a hanger (11, 12), and a guide rod 8; the hanger (11, 12) is set on the fixed bracket 7 on the same side, one is respectively arranged at the left and right ends, and a connecting hole is provided on the suspension seat (11, 12). There is a positioning handle 13, which can pull out the guide bar 8 outward; the boom 9 is connected to the guide bar 8 and can move left and right on the guide bar 8; the laser profiler 6 and the arm 9 are fixedly connected by bolts, The laser emitting direction of the laser profiler 6 is located at the same level as the disk spring 4 on the turbine casing 1 .

[0027] The position deviation of points A and B at the maximum outer diameter of the section of the disc spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com