Hard disk installation equipment for video data storage

A technology for video data and installation equipment, applied in the direction of electrical digital data processing, digital data processing components, digital processing power distribution, etc., can solve problems such as low efficiency, easy loosening of hard disks, and inability to ensure the effect of screw tightening, etc., to achieve convenience Installation, to avoid the effect of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

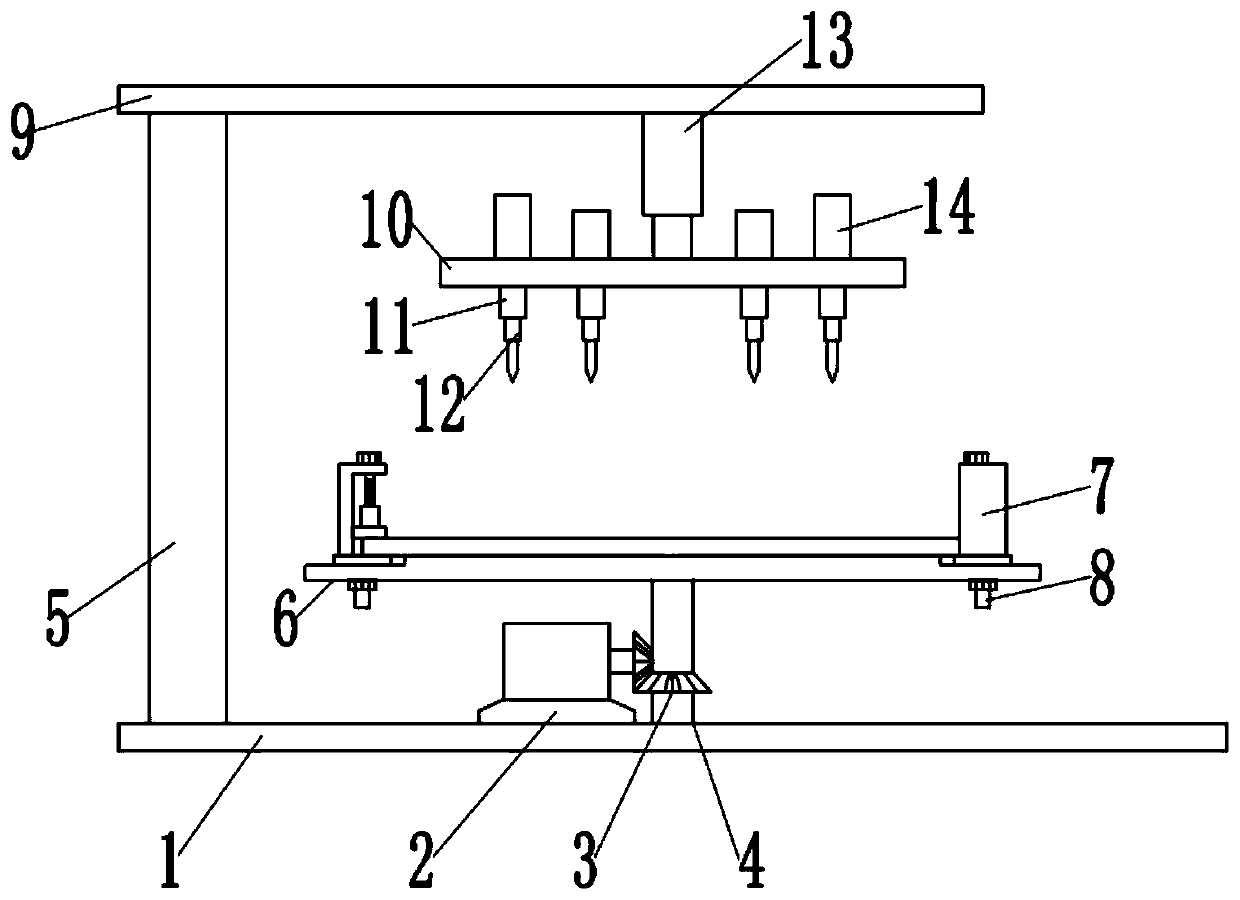

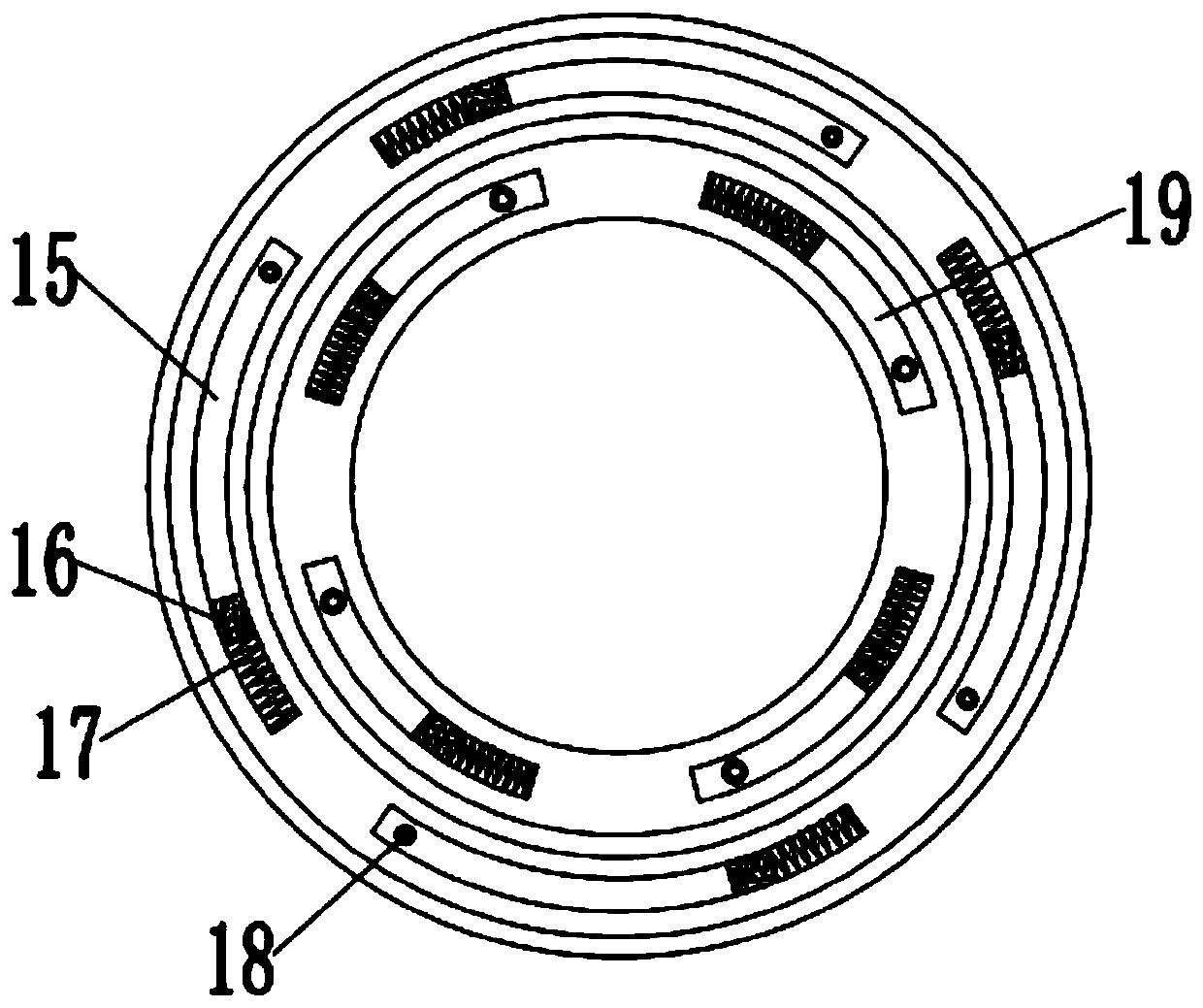

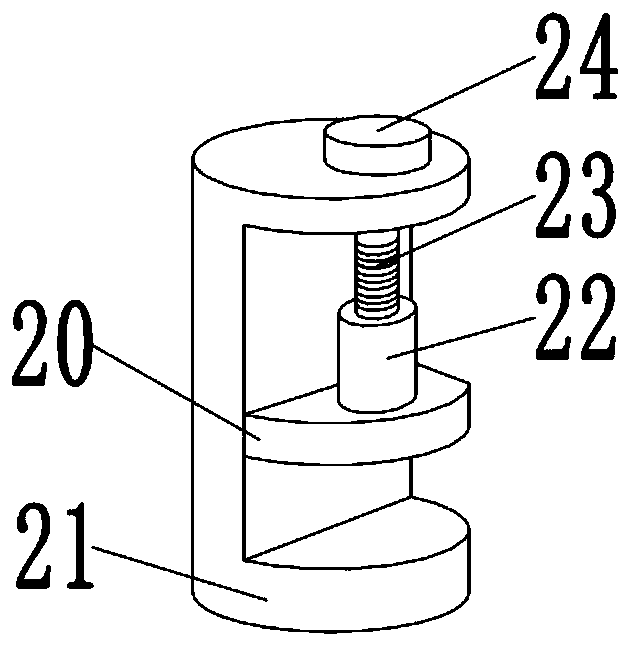

[0027] see Figure 1-2 , in an embodiment of the present invention, a hard disk installation device for video data storage includes a base plate 1, a workbench 6 and a lifting platform 10; a pillar 5 is fixedly installed on the left side of the base plate 1, and a top plate is fixedly installed on the upper end of the pillar 5 9. A lifting platform 10 is arranged under the top plate 9, and the working platform 6 is installed on the bottom plate 1 through the rotating shaft 4. The lifting platform 10 fixes and installs the hard disk on the working platform 6, so that the hard disk is effectively installed in the hard disk rack superior;

[0028] Specifically, in this embodiment, a driving motor 2 is fixedly installed on the base plate 1, and the output end of the driving motor 2 is connected to the rotating shaft 4 through a bevel gear set 3, so as to drive the rotating shaft 4 to rotate;

[0029] The bottom of the top plate 9 is fixedly installed with a hydraulic rod 13, and ...

Embodiment 1-2

[0034] Embodiment 1-2, in the embodiment of the present invention, a hard disk installation device for video data storage includes a base plate 1, a workbench 6 and a lifting platform 10; a pillar 5 is fixedly installed on the left side of the base plate 1, and the The top plate 9 is fixedly installed on the upper end, and a lift table 10 is arranged below the top plate 9. The workbench 6 is installed on the base plate 1 by rotating the rotating shaft 4. The lift table 10 fixes and installs the hard disk on the workbench 6, so that the hard disk Effectively installed on the hard disk rack;

[0035] Specifically, in this embodiment, a driving motor 2 is fixedly installed on the base plate 1, and the output end of the driving motor 2 is connected to the rotating shaft 4 through a bevel gear set 3, so as to drive the rotating shaft 4 to rotate;

[0036] The bottom of the top plate 9 is fixedly installed with a hydraulic rod 13, and the lifting platform 10 is fixedly installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com