Mixing and stirring device for livestock feed

A mixing and feeding technology, which is applied in the field of animal husbandry, can solve the problems of insufficient uniformity, excessive consumption of medicines, low mixing efficiency of medicines and feeds, and achieve the effects of convenient control, uniformity of materials, and improvement of passing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

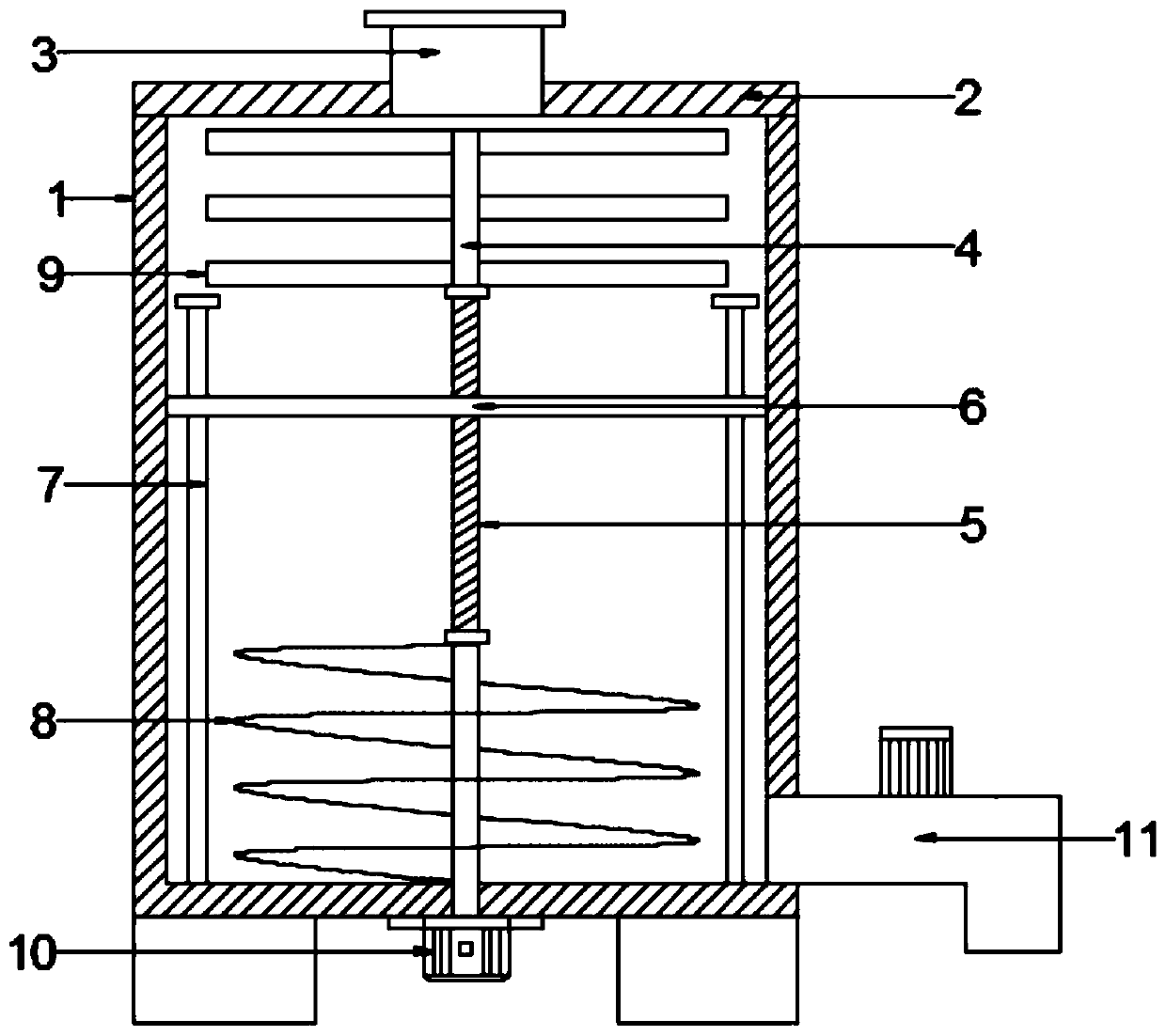

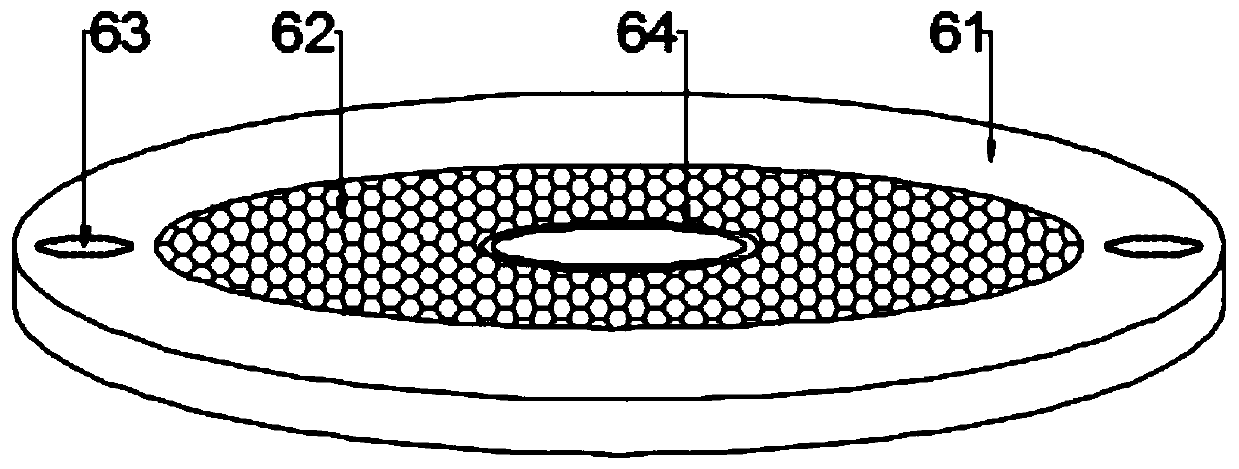

[0024] see Figure 1~2 , in an embodiment of the present invention, a mixing and stirring device for livestock feed includes a housing 1, and a stirring mechanism is connected to the housing 1, and the stirring mechanism includes a stirring assembly and a homogenizing assembly, and the stirring assembly and a homogenizing assembly The components are synchronously driven by the driving mechanism. The stirring mechanism is also provided with a lifting mechanism for refining materials to prevent agglomeration. The bottom side of the housing 1 is also connected with a discharge pipe 11. The discharge pipe 11 A bump 15 is fixedly connected in the middle, and a guiding mechanism for promoting material export is arranged on the bump 15 in cooperation with the connection.

[0025] The upper end of the housing 1 is provided with an upper cover 2 through riveting or screw connection, and the middle part of the upper cover 2 is connected with a feed pipe 3, through which materials are pu...

Embodiment 2

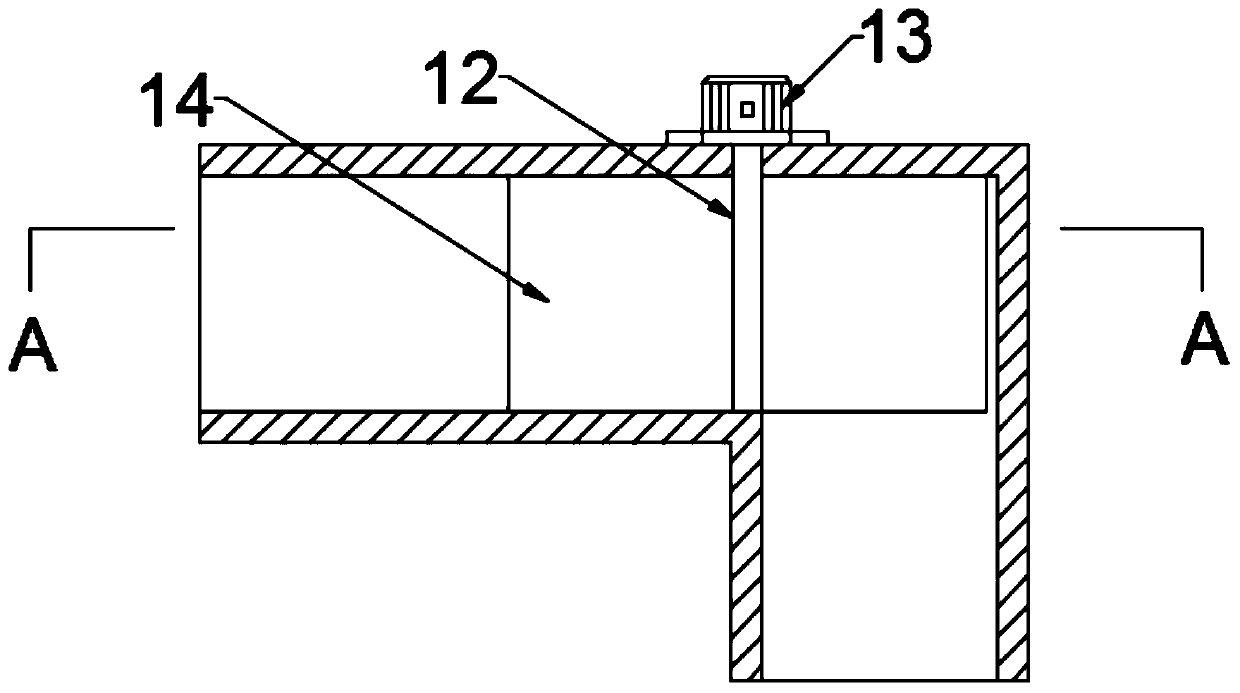

[0031] see Figure 3-4 , In the embodiment of the present invention, the discharge pipe 11 is an "L"-shaped pipe, the cross section of the discharge pipe 11 is rectangular, and one end communicates with the housing 1, and the other end is bent downward.

[0032] The bumps 15 are provided with two groups, which are respectively located on the opposite side walls of the discharge pipe 11. The opposite sides of the bumps 15 are arc-shaped, and the centers of the arcs of the opposite sides of the bumps 15 overlap.

[0033] The guide mechanism includes a second rotating shaft 12 that is rotatably connected to the center of the arc of the side of the projection 15 and a material guide blade 14 that is fixedly connected to the periphery of the second rotation shaft 12. The edge of the material guide blade 14 and the projection 15 are arc-shaped The side is movable and fitted, the upper and lower surfaces of the material guide blade 14 are movably fitted with the inner wall of the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com