Stabilizing device for steel plate welding

A technology for stabilizing devices and steel plates, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as large welding errors of steel plates, deviation of steel plate positions, etc., and achieve rapid cooling, convenient handling, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

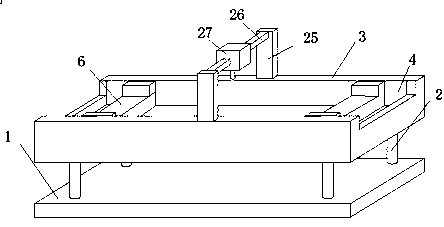

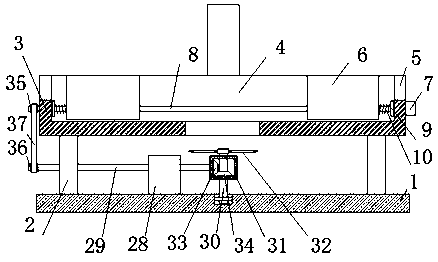

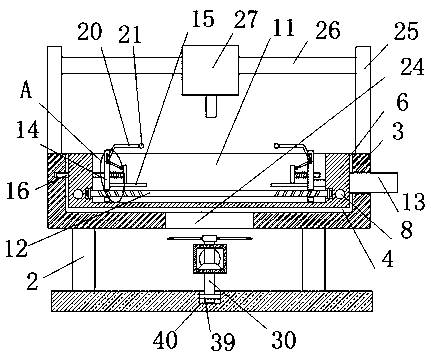

[0028] refer to Figure 1-5 , a stabilizing device for steel plate welding, comprising a base 1, four symmetrically arranged support legs 2 are fixedly installed on the top of the base 1, and the same operation platform 3 is fixedly installed on the top of the four support legs 2, and the operation platform 3 The top of the sliding groove 4 is provided with a sliding groove 4, and the inner wall of both sides of the sliding groove 4 is provided with a through groove 5. Two symmetrically arranged moving plates 6 are slidably connected in the sliding groove 4, and a motor 7 is fixedly installed on one side of the console 3. The inner wall of the slide groove 4 is rotationally connected with two symmetrically arranged two-way screws 8, and one of the two two-way screws 8 is fixedly connected with the output shaft of the motor 7, and the two two-way screws 8 are all connected to the two moving plates. 6 sliding connection, the top of the moving plate 6 is provided with a placement...

Embodiment 2

[0039] refer to Figure 1-5 , a stabilizing device for steel plate welding, comprising a base 1, four symmetrically arranged support legs 2 are welded on the top of the base 1, the same operating platform 3 is welded on the top of the four supporting legs 2, and the top of the operating platform 3 A sliding groove 4 is provided, and through grooves 5 are provided on the inner walls of both sides of the sliding groove 4. Two symmetrically arranged moving plates 6 are slidably connected in the sliding groove 4, and a motor 7 is welded on one side of the console 3. The sliding groove 4 Two symmetrically arranged two-way screws 8 are rotationally connected on the inner wall of the two-way screw rod 8, and one two-way screw rod 8 in the two two-way screw rods 8 is fixedly connected with the output shaft of the motor 7, and the two two-way screw rods 8 are all slidably connected with the two moving plates 6 , the top of the moving plate 6 is provided with a placement groove 11, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com