Board fixed-length cutting device for composite board production line

A technology of cutting device and production line, which is applied in metal processing and other directions, can solve the problems of low production efficiency, many production processes, and low cutting precision, and achieve the effect of one-step cutting, fewer production processes, and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

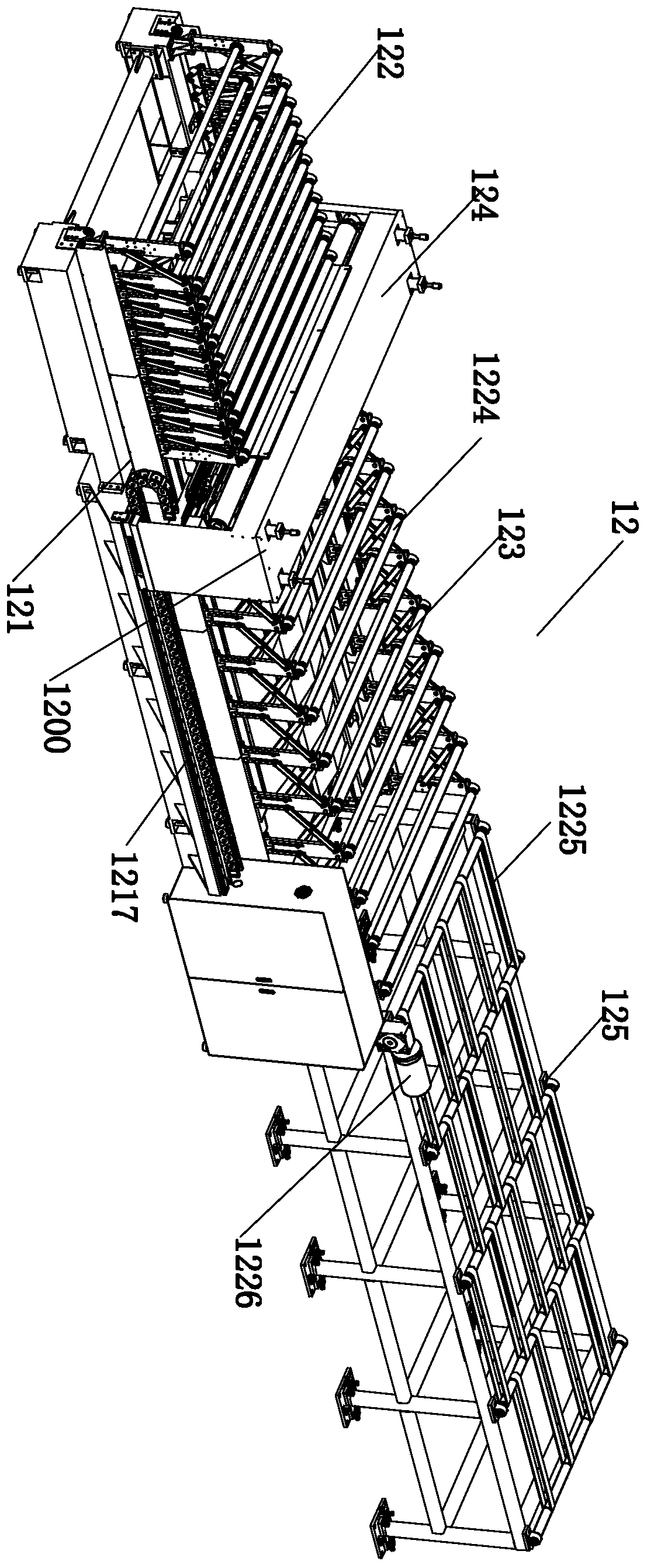

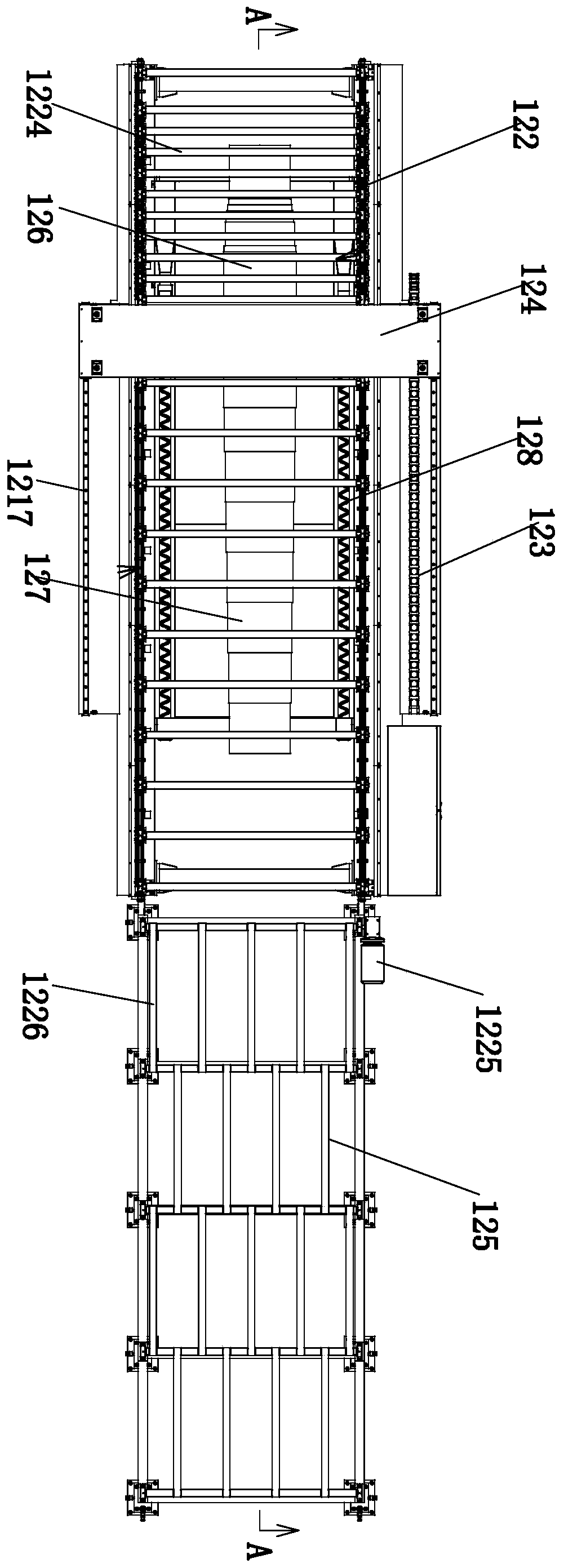

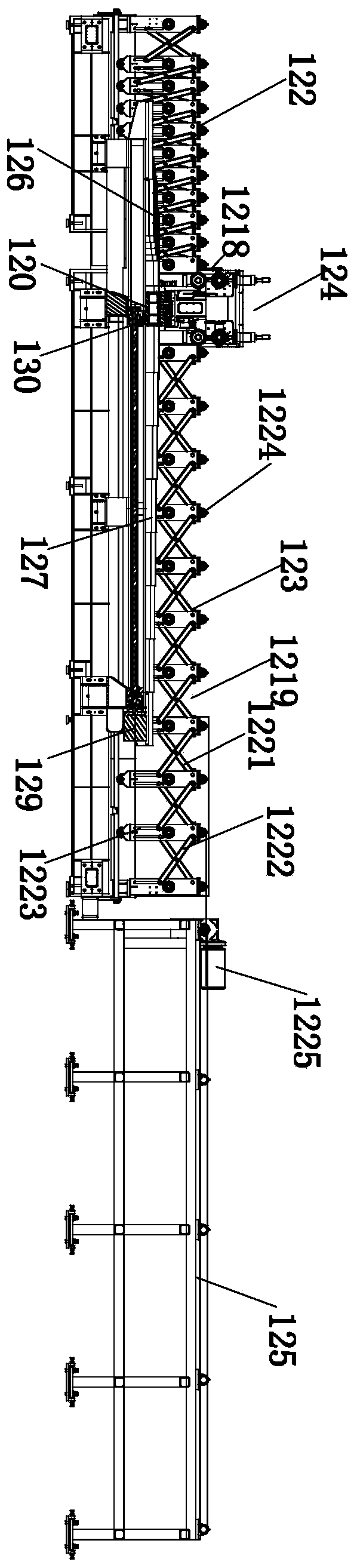

[0032] Embodiment one, such as Figure 1 to Figure 8 As shown, a board fixed-length cutting device 12 of a composite board production line includes a controller (not shown in the figure), a fixed-length cutting frame 121, a front telescopic support frame 122, a rear telescopic support frame 123, and a cutting knife walking mechanism 124. Spiral automatic chip removal machine 128, front dust cover 126, rear dust cover 127 and fixed-length transition frame 125, the front telescopic support frame, cutter walking mechanism and rear telescopic support frame cut off the frame along the fixed length The feeding direction is horizontally slidably arranged on the fixed-length cutting frame. The cutting knife traveling mechanism 124 is located between the front telescopic support frame 122 and the rear telescopic support frame 123. The front end of the telescopic support frame 123, the cutting knife traveling mechanism 124 includes a walking frame 120, a cutting knife assembly, a travel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com