Dual shuttle open type rubber ball pin vulcanization mold

A technology for vulcanizing molds and rubber balls, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of cumbersome placement of skeletons and inserts, time-consuming and laborious core inserts, and easy damage to core inserts. The effect of avoiding flash and the time consumed by subsequent processing of flash, improving efficiency and shortening production cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

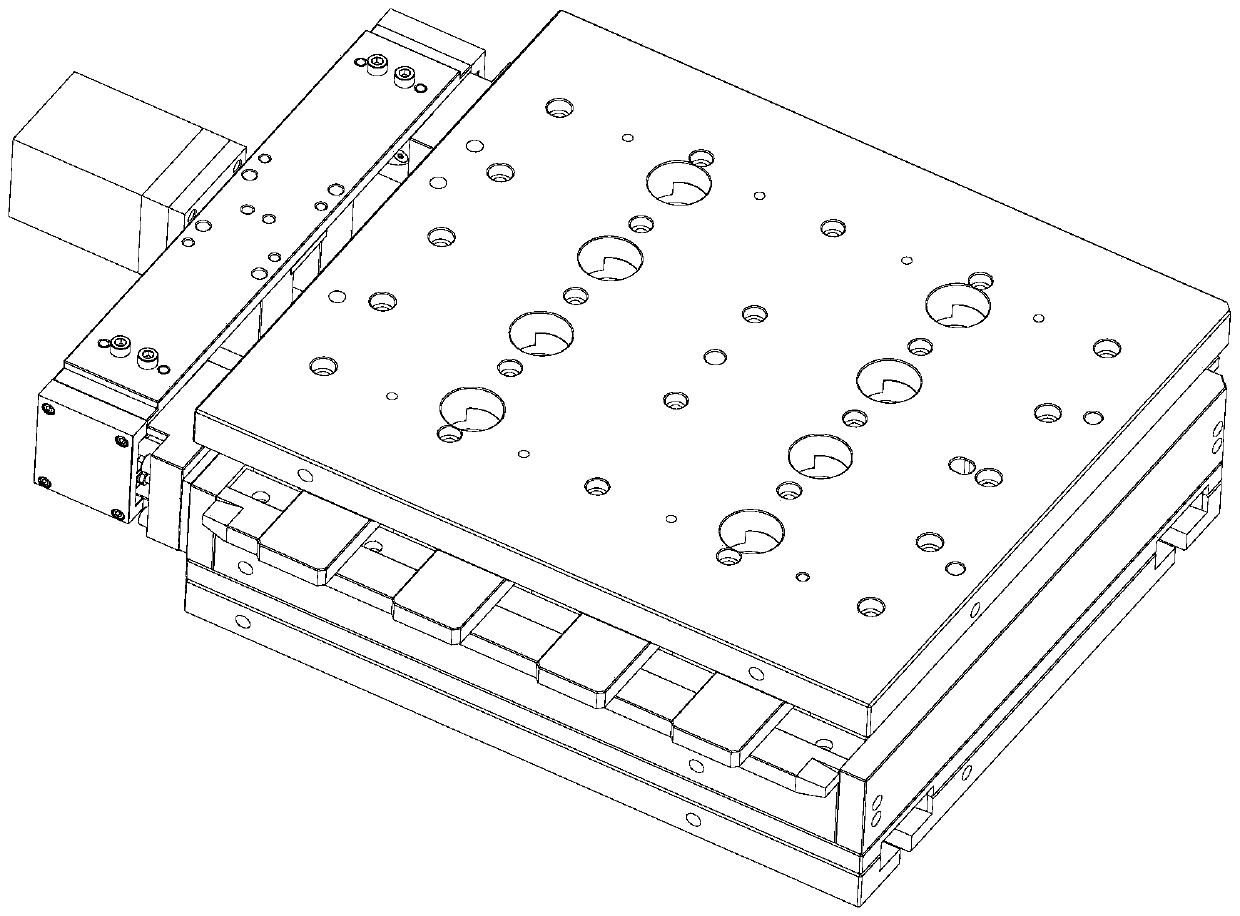

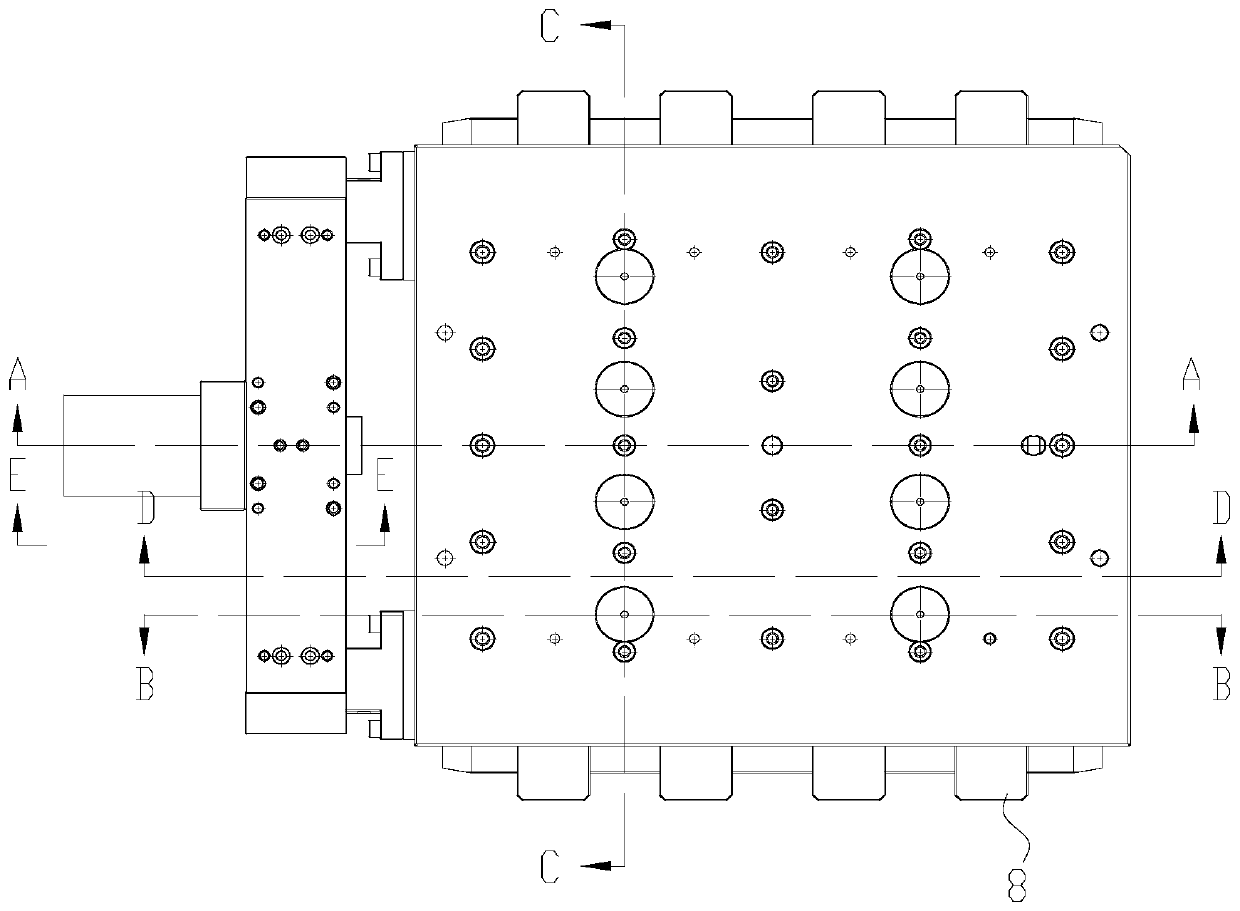

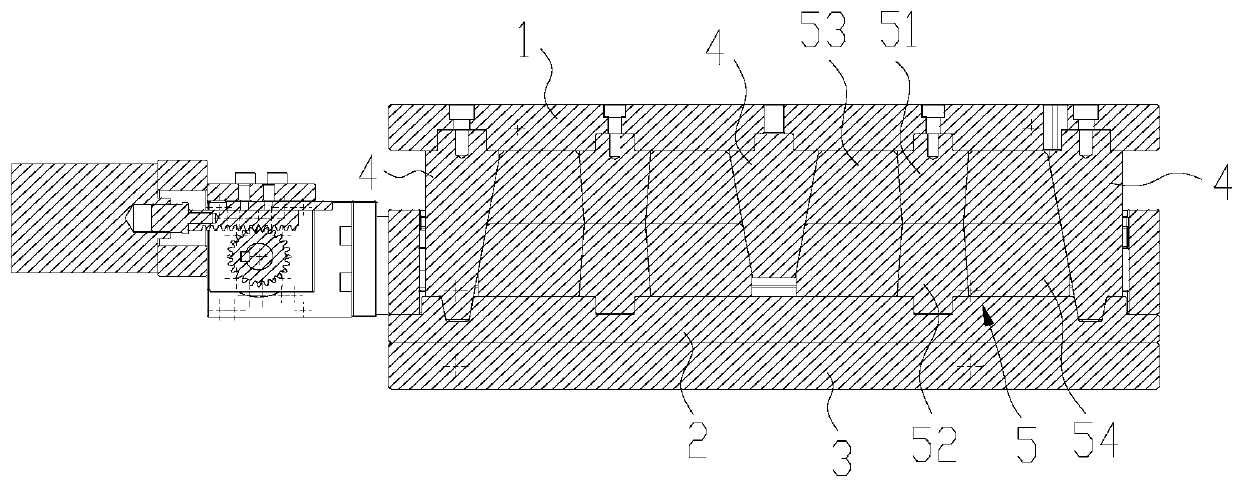

[0036] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0037] like Figure 1-10 As shown, the double-shuttle open type rubber ball pin vulcanization mold includes a runner plate 1, a bottom plate 2 and a base 3. The lower part of the runner plate 1 is fixedly connected with several partition bars 4 at intervals along the transverse direction, and there is a gap between two adjacent partition bars 4. Group vulcanization module 5;

[0038] The vulcanization module 5 includes a middle upper template 51, a middle lower template 52, two side upper templates 53 and two side lower templates 54, the two side upper templates 53 are symmetrically arranged on both sides of the middle upper template 51, and the two side lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com