Obstacle clearing device with detection mechanism for rail transit

A technology of detection mechanism and obstacle removal device, which is applied in the field of rail transit, can solve the problems of double-layer rubber plate damage, low service life, and huge impact energy of sundries, and achieve the effect of prolonging service life and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

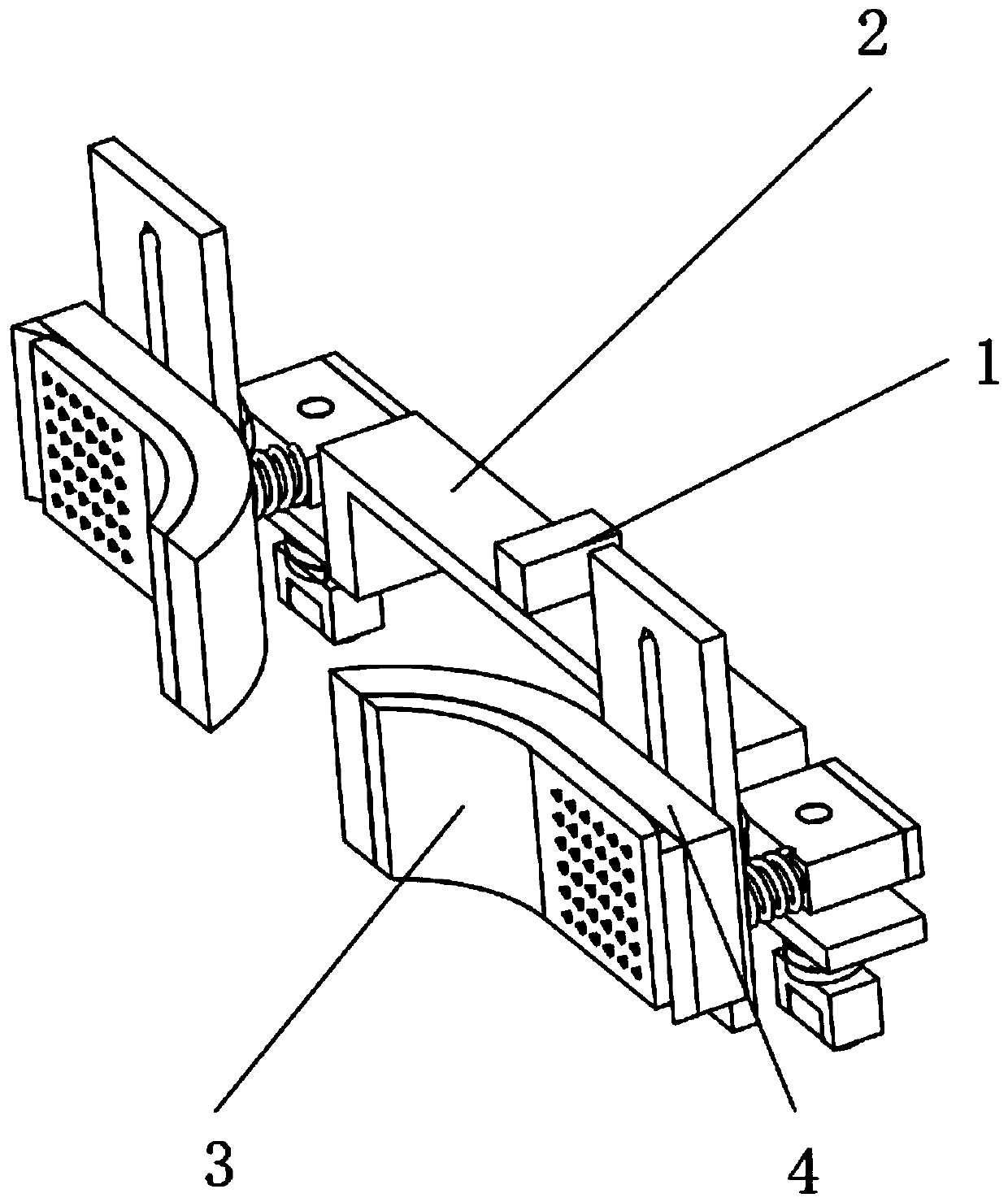

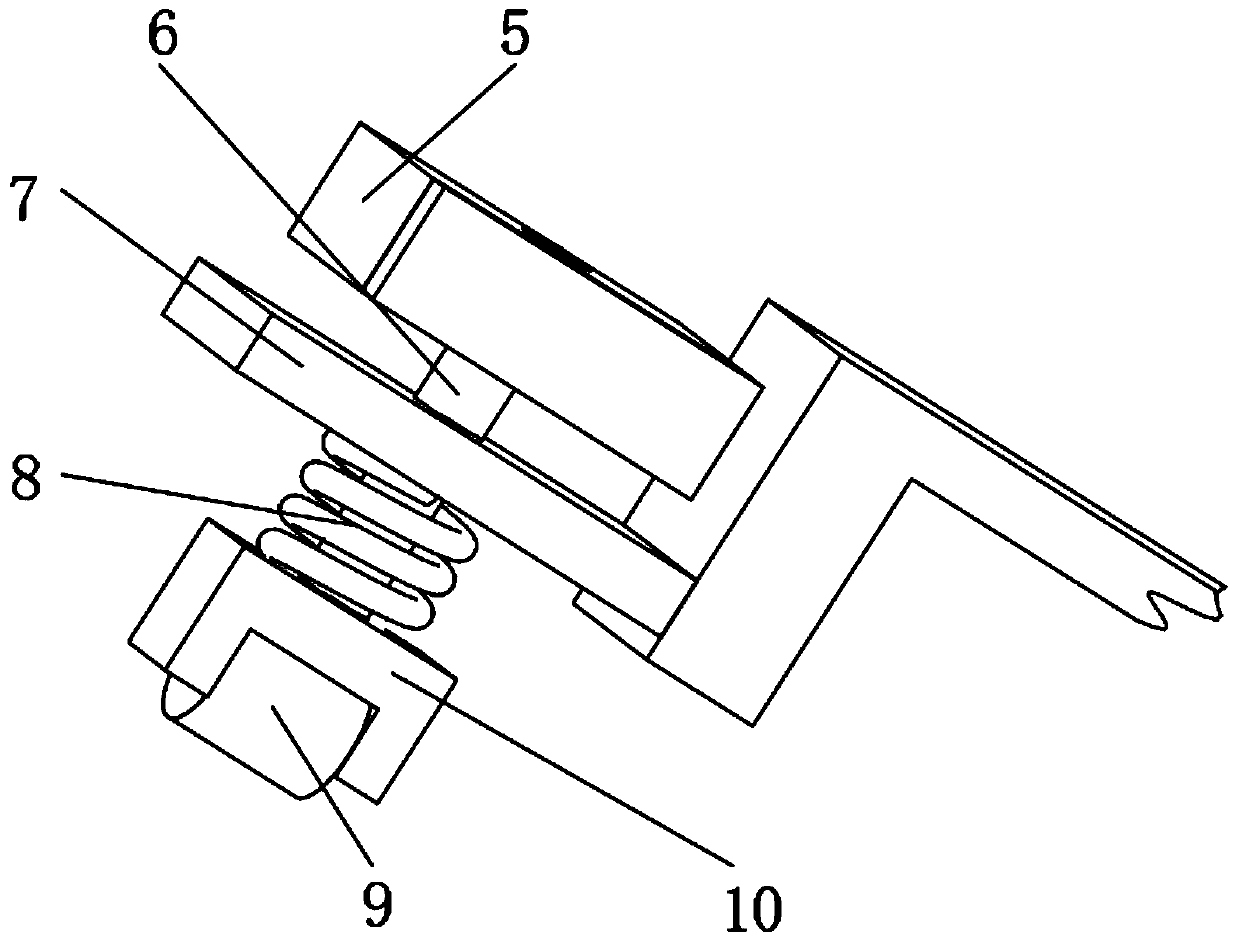

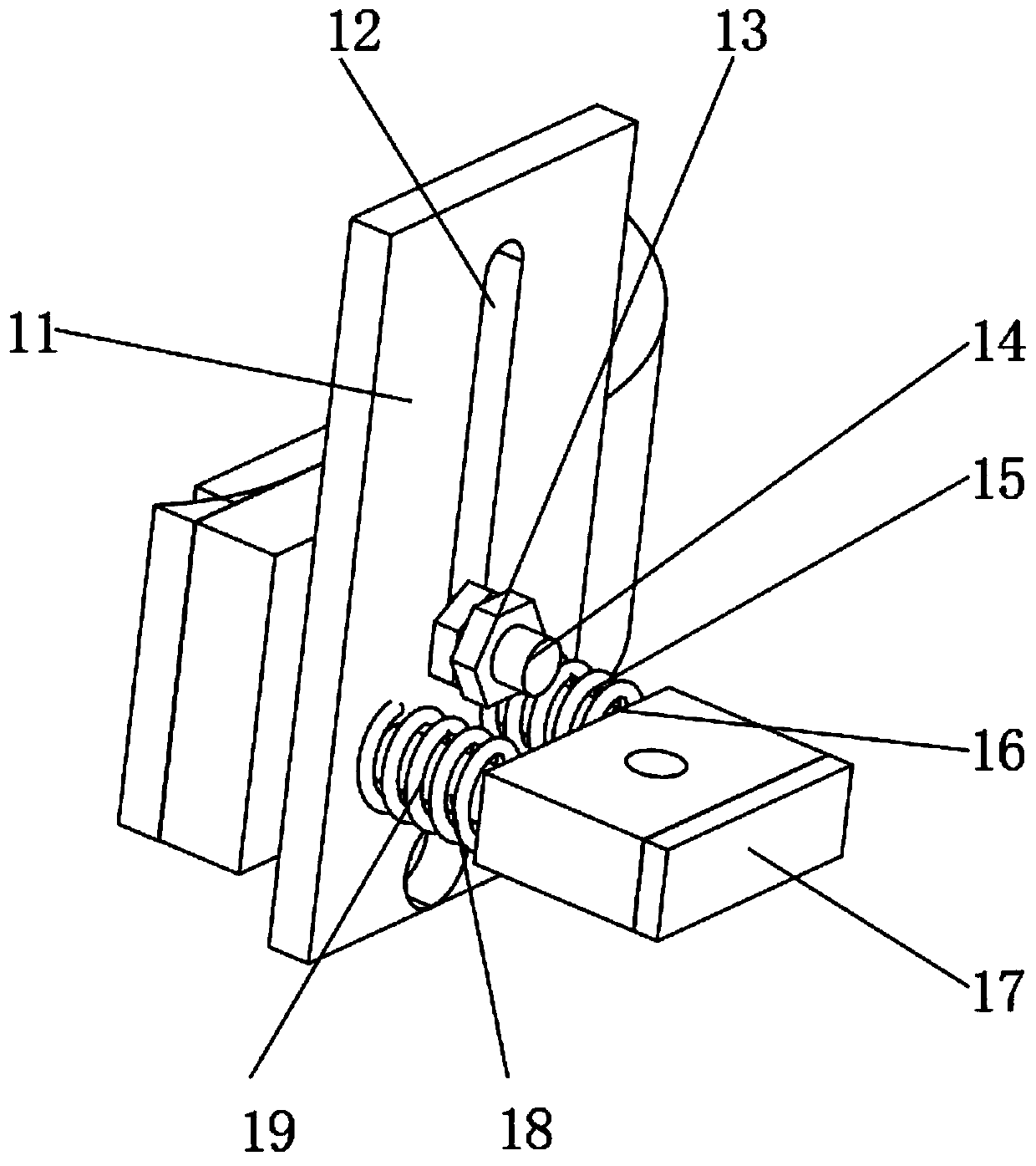

[0035] A kind of obstacle removal device with detection mechanism for rail transit, such as figure 2As shown, it includes the connecting steel plate 1 fixed on the bottom of the head car compartment and the electronic system placed in the cab, the outer wall of the bottom of the connecting steel plate 1 is fixed with the connecting beam 2 by bolts, and the outer wall of the connecting beam 2 is fixed with an anti-contact steel plate by bolts 7. The inner wall of the anti-contact steel plate 7 is provided with an anti-contact device, one side of the anti-contact device is provided with a clearing mechanism, and the opposite side of the clearing mechanism and the anti-contact device is provided with the same buffer mechanism; the connecting steel plate 1 is fixed in the direction of train travel At the bottom of the carriage at the front end, the connecting beam 2 is fixedly connected to the connecting steel plate 1 as the support of the whole device, and the device is arranged ...

Embodiment 2

[0041] A kind of obstacle removal device with detection mechanism for rail transit, such as Figure 4 , 6 As shown, in order to solve the problem that the electronic system can detect the number of times of obstacle removal and the pressure change of the impact rubber 3 during the obstacle removal process; this embodiment makes the following improvements on the basis of embodiment 1: the electronic system includes an electronic control system and Auxiliary structure, the electric control system includes piezoelectric ceramics 20 and a main board 29, the piezoelectric ceramics 20 is embedded on the inner wall of the impact rubber 3, the piezoelectric ceramics 20 is electrically connected with the main board 29, and the top outer wall of the main board 29 is respectively welded with signal conversion Module 31, central processing module 32, counting module 33 and control module 34, signal conversion module 31, central processing module 32, counting module 33 and control module 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com