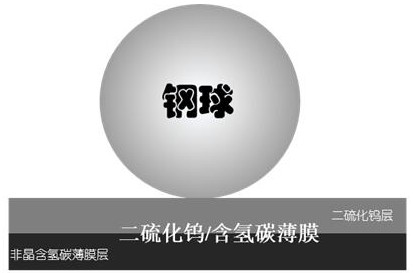

A kind of ultra-smooth tungsten disulfide/hydrogen-containing carbon film and its preparation method

A technology of tungsten disulfide and carbon thin film, which is applied in gaseous chemical plating, superimposed layer plating, vacuum evaporation plating, etc., can solve difficult engineering applications and other problems, and achieve reliable selection, improved lubrication performance, and wear resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Ultrasonic cleaning the base material (which can be bearing steel, gear steel, etc.) to remove rust spots and dirt, check the surface of the plated parts after cleaning to ensure that there are no rust spots and defects; put it into the vacuum coating chamber, and evacuate to Below 0.001 Pa, start coating;

[0036] (2) Using hollow cathode plasma to prepare hydrogen-containing carbon film, the specific steps are:

[0037] a. Inject argon gas at 2Pa, hollow cathode current 300-400A, bias voltage 800V, duty cycle 80%, and clean for 30 minutes to further remove pollutants on the surface of the workpiece;

[0038] b. Replace argon with 2Pa 5% silane gas mixture, hollow cathode current 300A, bias voltage 200-400V, duty cycle 80%, deposit silicon bonding layer for 30 minutes;

[0039] c. Gradually introduce methane within 30 minutes, until the ratio of methane and 5% silane gas mixture is 1:1, keep for 20 minutes;

[0040] d. Turn off the 5% silane mixed gas, feed the s...

Embodiment 2

[0044] (1) Ultrasonic cleaning the base material (which can be bearing steel, gear steel, etc.) to remove rust spots and dirt, check the surface of the plated parts after cleaning to ensure that there are no rust spots and defects; put it into the vacuum coating chamber, and evacuate to Below 0.001 Pa, start coating;

[0045] (2) The anode layer ion source is used to assist in the preparation of hydrogen-containing carbon films, and the specific steps are:

[0046] a. Introduce 3Pa argon gas, anode layer ion source voltage 1500-2000V, bias voltage 800V, duty cycle 60%, and clean for 30 minutes to further remove pollutants on the surface of the workpiece;

[0047] b. Replace the argon gas with 2Pa 5% silane gas mixture, the anode layer ion source voltage is 1000-1200V, the bias voltage is 200-400V, the duty cycle is 60%, and the silicon bonding layer is deposited for 40 minutes;

[0048] c. Gradually introduce methane within 30 minutes, until the ratio of methane and 5% silane g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com