Weaving method of netty fabric

A fabric and mesh technology, applied in the field of weaving mesh fabrics with knots, can solve the problems of unsuitable monofilament, large knot shape and low output, and achieve the effects of convenient knot formation, high output and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

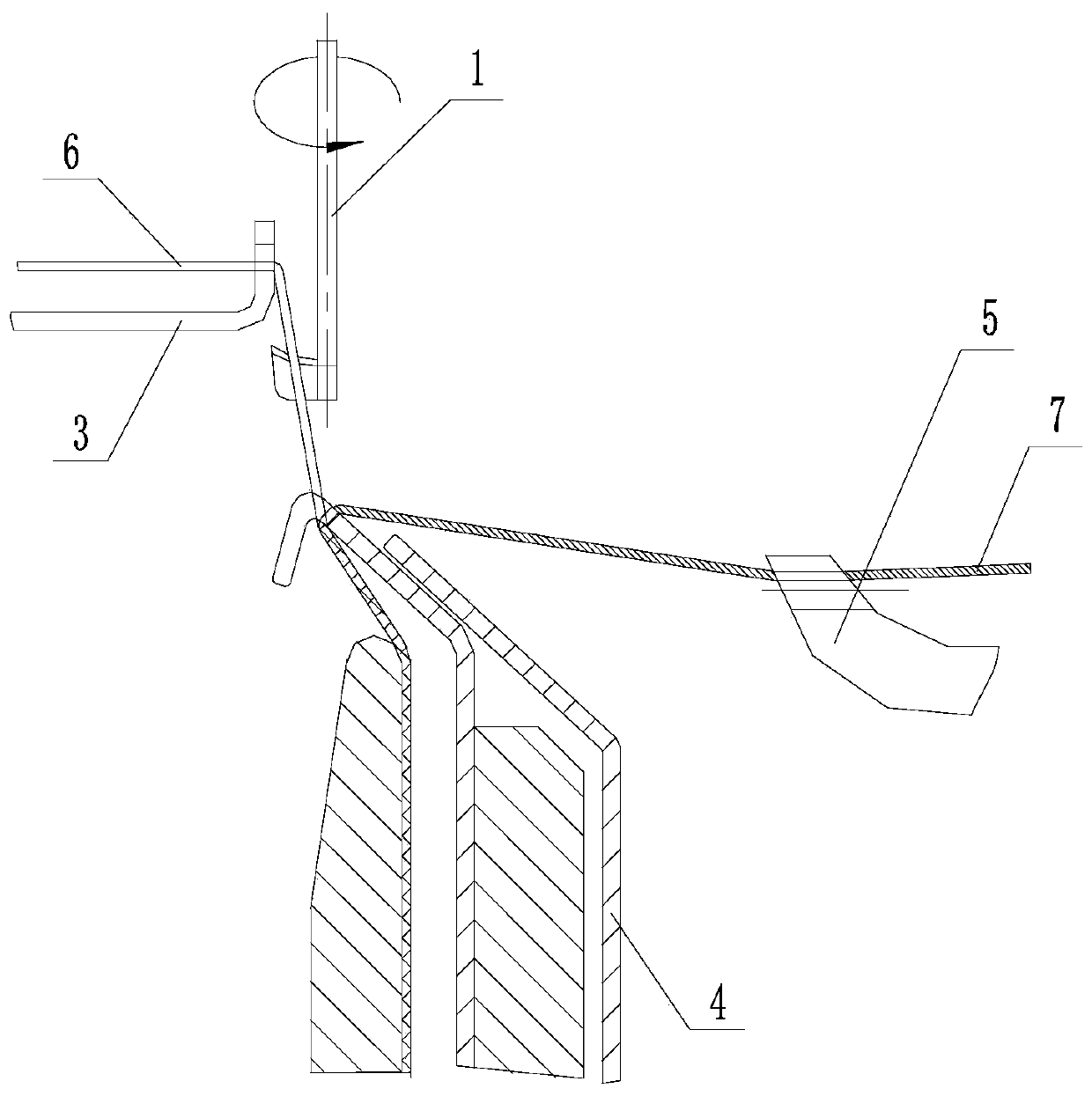

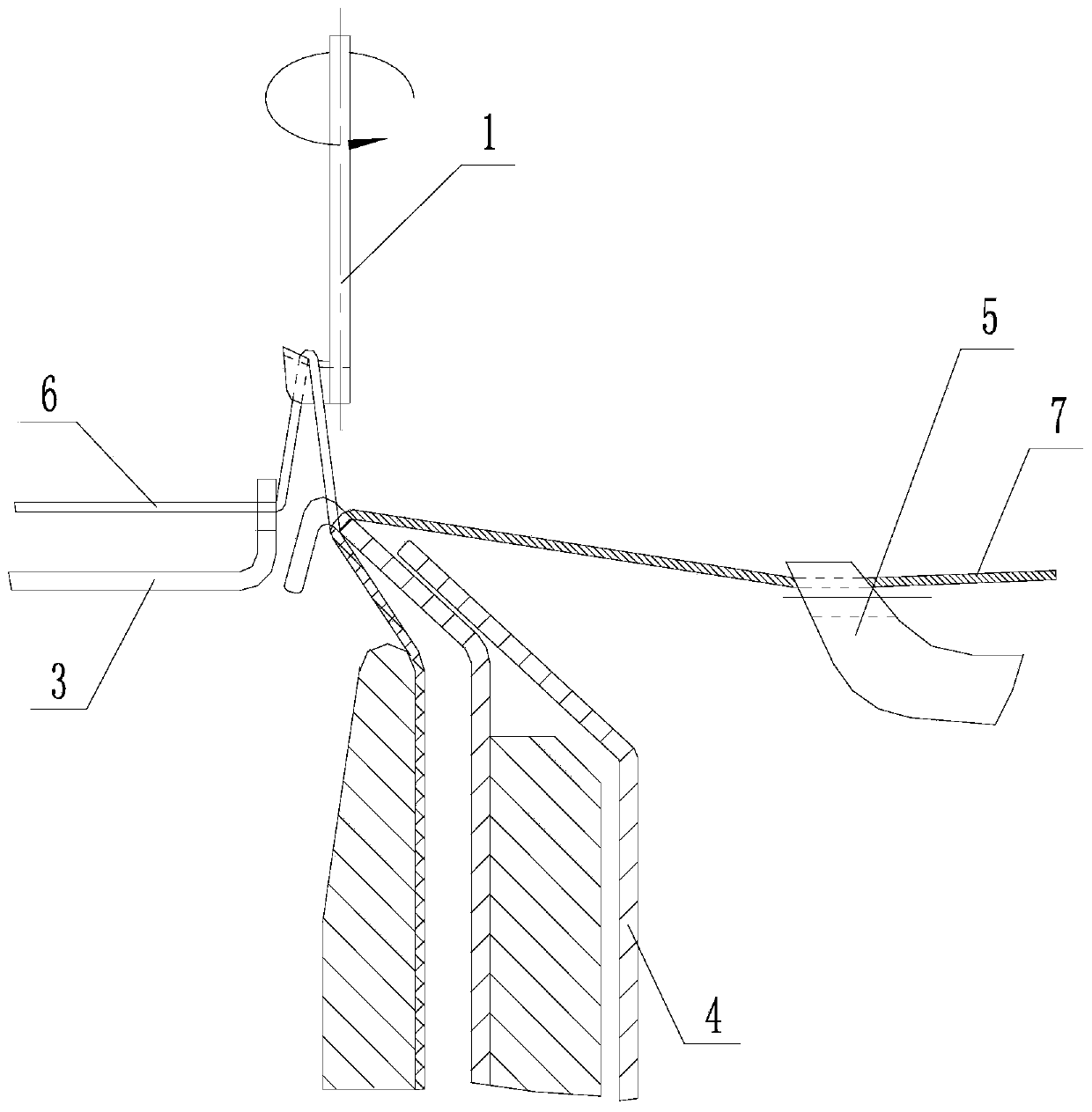

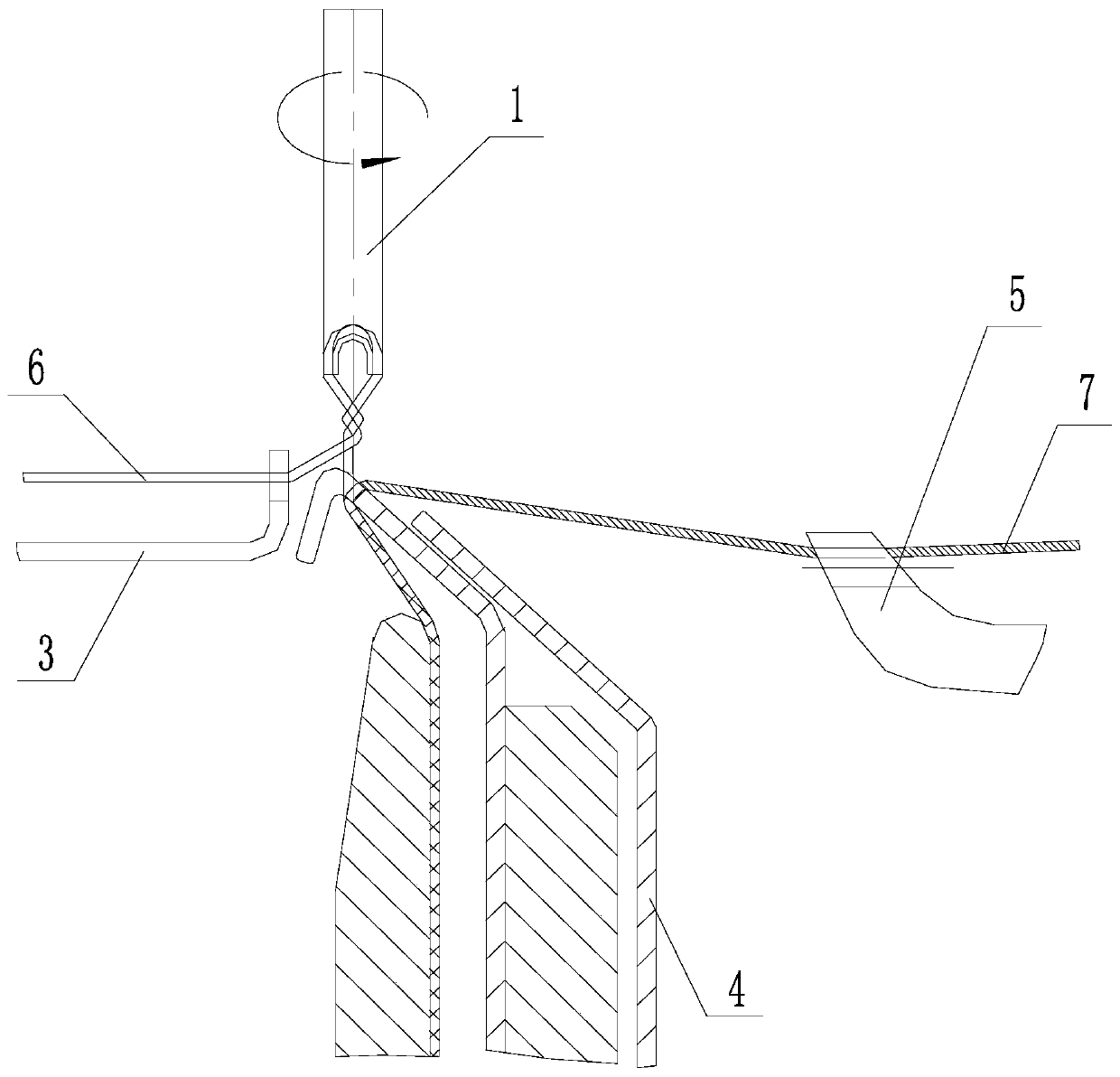

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] see Figures 1 to 8 Shown, a kind of weaving method of knotted net-like fabric, this method adopts the knitting machine that comprises upper hook 1, lower hook 2, orifice plate 3, top weft plate 4, shuttle 5 and wire reel, and warp thread 6 passes through orifice plate 3 Inside, the weft thread 7 is wound in the coil. In this example, the method includes the following steps:

[0027] 1) Viewed from the rear of the machine, upper hook 1 resets to the right or left, then upper hook 1 hook tip swings to the side of orifice plate 3, and rotates counterclockwise around itself for 0.25-0.5 circles. During this process, the hole The plate 3 guides the warp thread 6 around the upper hook 1, and the upper hook 1 hooks to the warp thread 6 and continues to rotate counterclockwise for 1.75-1.5 turns to form a warp coil;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com