Water heater surface cover component bonding tool

A technology for water heaters and masks, which is applied in the field of bonding tooling for water heater masks, which can solve problems such as product side scratches, large assembly stress, and glass panel bursts, and achieve the effects of avoiding burst accidents, ensuring accuracy, and ensuring aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

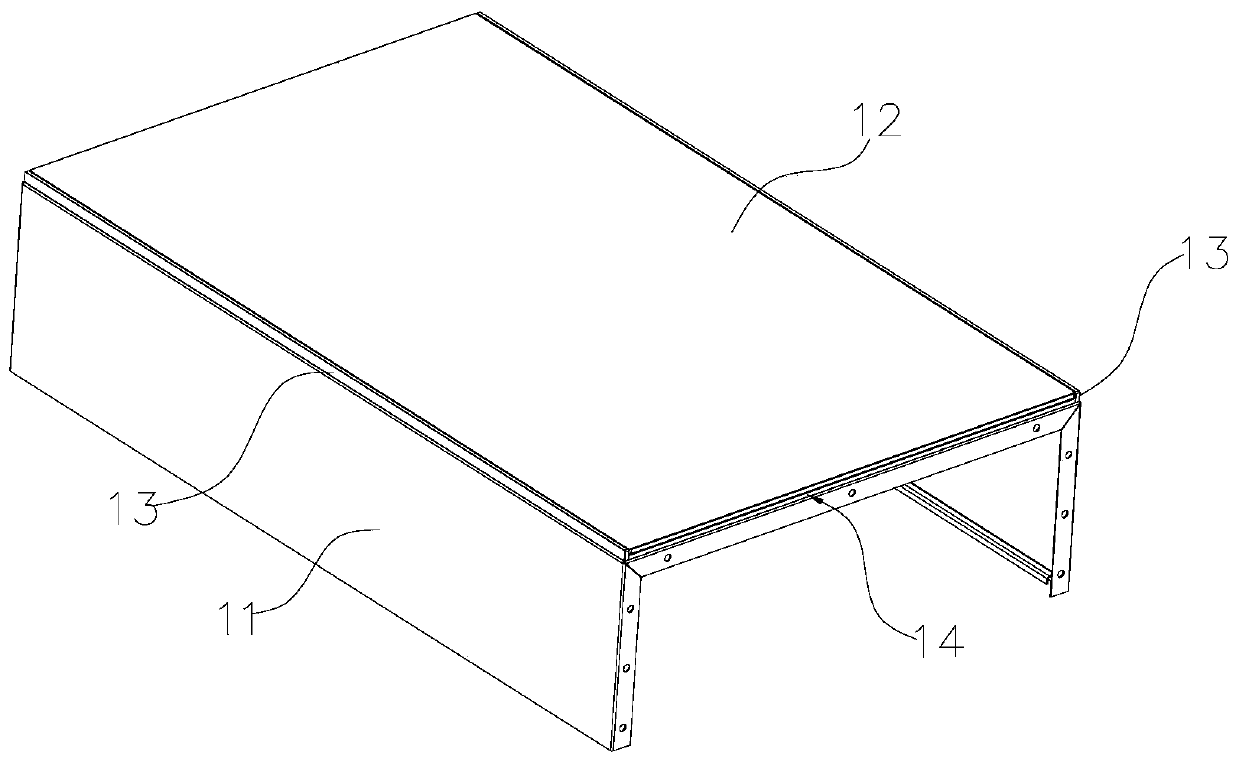

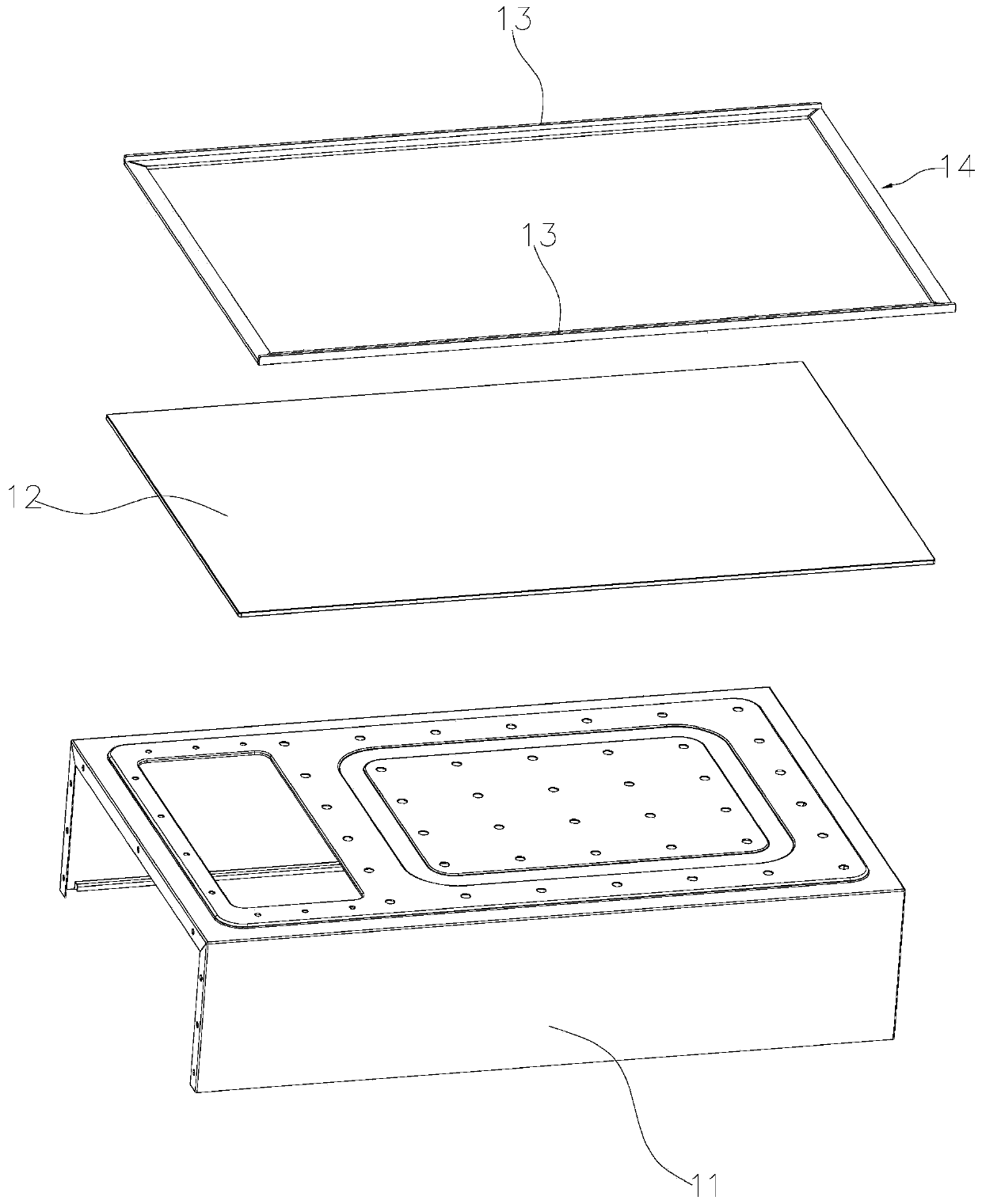

[0031] like Figure 1-12 As shown, a water heater mask assembly bonding tooling, the water heater mask assembly in the present invention includes a glass panel assembly and a mask body 11, the glass panel assembly includes a glass panel 12, a glass decorative strip 13 and a glass bead 14, the mask body 11 It includes the front side and the sides on both sides, and the front side is provided with small holes. During bonding, at first glass panel, glass decorative strip 13 and glass bead 14 are bonded together to form glass panel assembly, thereby using bonding tool among the present invention glass panel assembly is bonded on the front of mask body 11 .

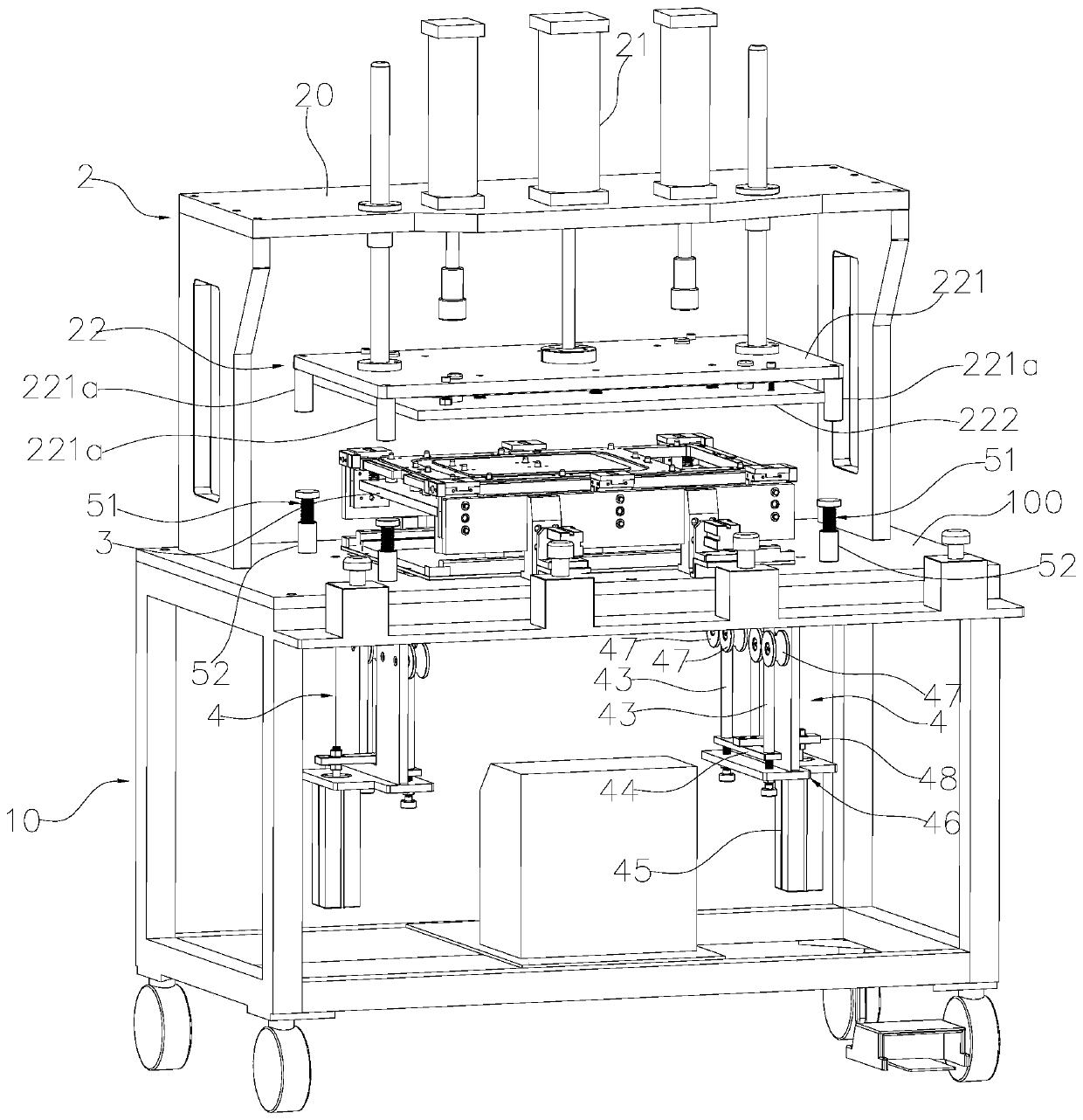

[0032] The above bonding tool includes an operation frame 10 with a workbench 100 , a stand 2 , a bonding frame 30 , an opening and closing positioning assembly 6 and an unloading assembly 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com