A non-destructive testing device for welded pipe joints

A technology of non-destructive flaw detection and welded pipes, which is applied in the direction of measuring devices, engine lubrication, instruments, etc., can solve the problems of high work intensity, reduced work efficiency, and low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

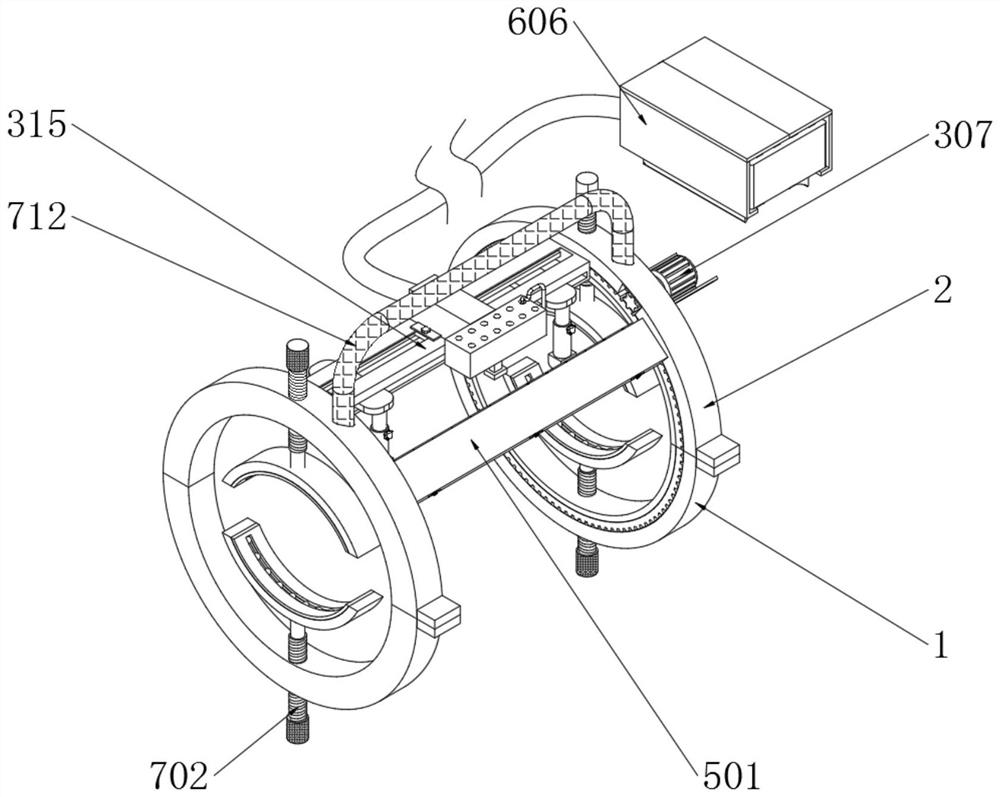

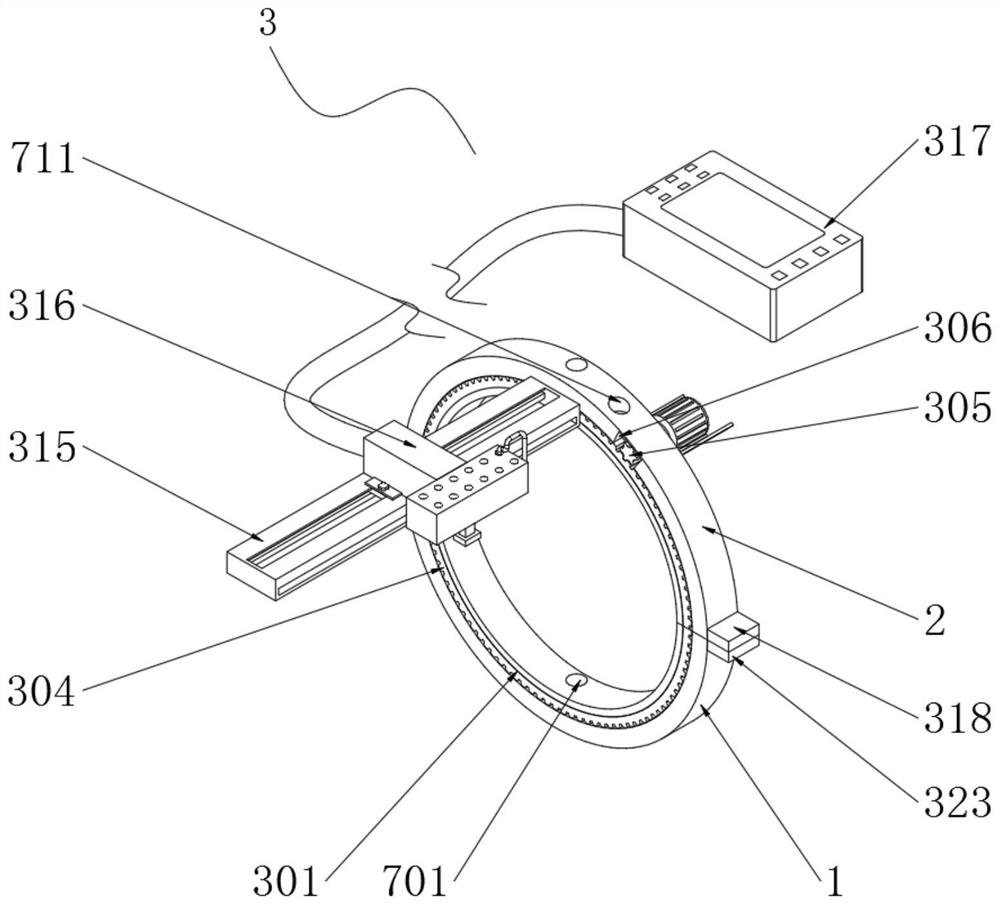

[0050] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a non-destructive flaw detection device for welded pipe joints, including two limiting rings 1 and two fixing rings 2, and one end of the adjacent limiting ring 1 is hinged with a fixing ring 2;

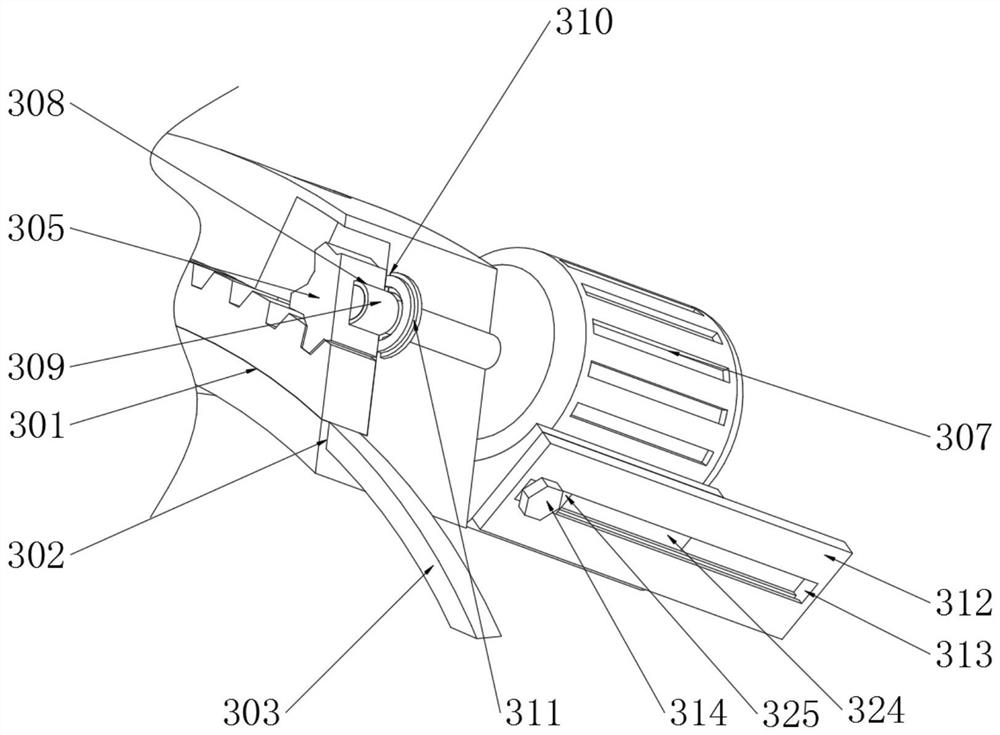

[0051] One end of the fixed ring 2 is equipped with a detection and fixing assembly 3, and the detection and fixing assembly 3 includes an installation groove 301, a limit groove 302, a limit ring 303, a ring gear 304, a gear 305, a gear groove 306, a driving motor 307, a driving groove 308, a rubber Cylinder 309, fixed card slot 310, collar 311, fixed plate 312, moving slot 313, limit screw 314, horizontal support platform 315, flaw detector 316, observer 317, fixed block 318, insertion column 319, movable plate 320, Connect the spring 321, the clamping plate 322, the corresponding block 323, the motor fixing seat 324, the T-shaped block 325 and the corresponding hole 326;

[0052] O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com