A kind of headlight light source and its manufacturing method

A manufacturing method and technology of light source, applied in the direction of headlights, motor vehicles, road vehicles, etc., can solve the problems of inability to real-time feedback intensity comparison and judgment, single beam collection function, waste of laser beam resources, etc. , Improve the driving safety factor and increase the effect of environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

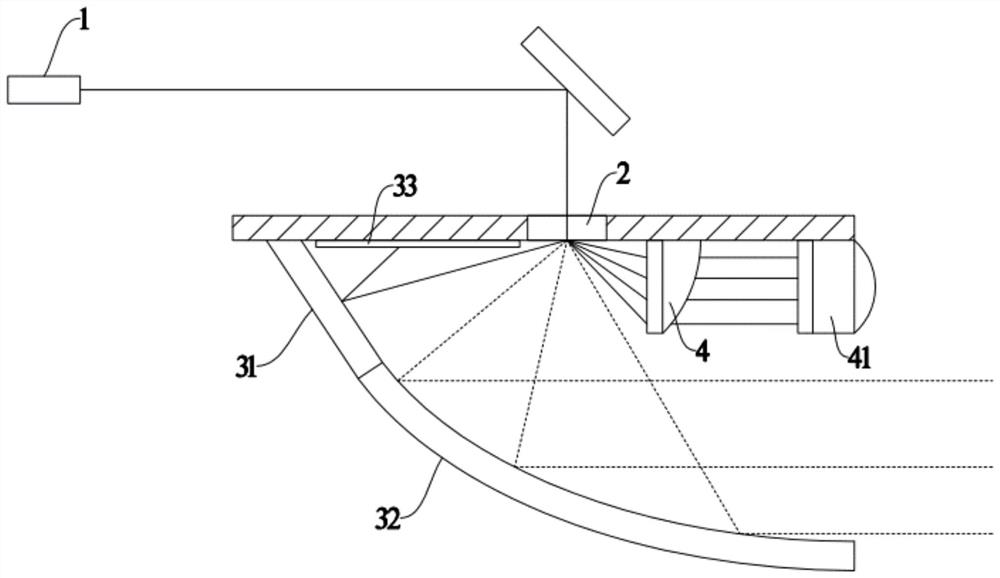

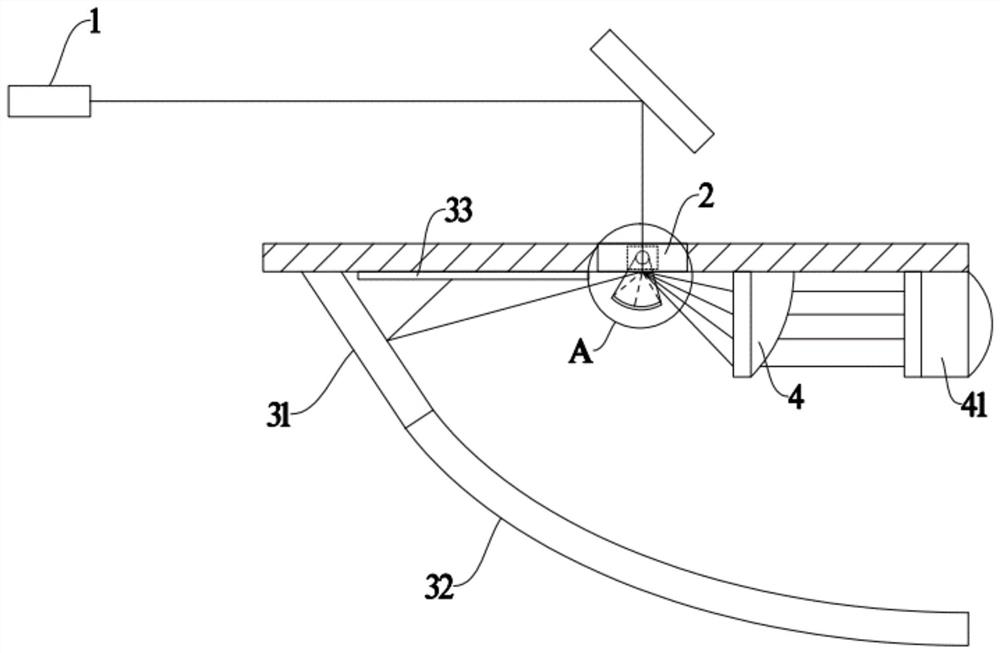

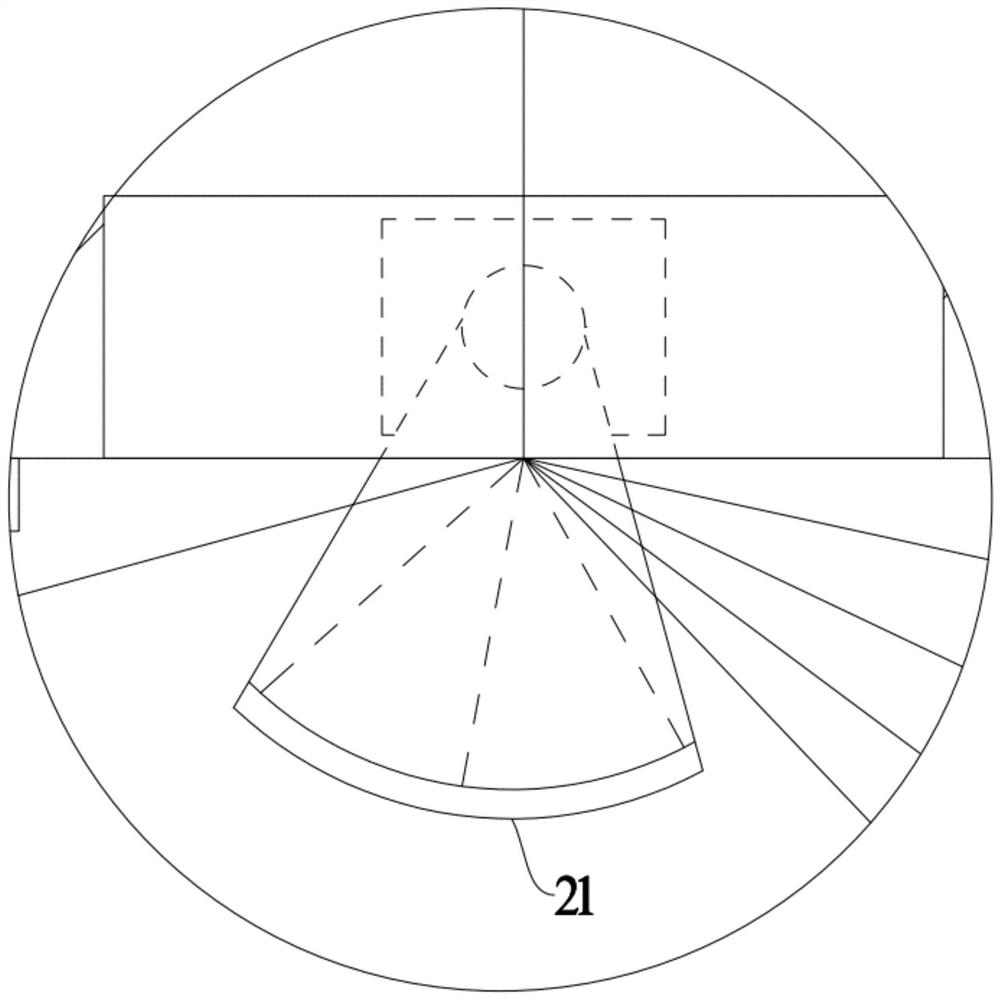

[0041] Such as Figure 1 to Figure 7 As shown, a car light source includes a light source assembly; the light source assembly includes a laser light source 1, a phosphor 2 and a multi-stage reflector; the phosphor 2 is excited by the laser light source 1 to emit light; the multi-stage The reflector has a flat cover surface 31 and a parabolic cover surface 32 arranged sequentially from back to front; the light emitted by the phosphor 2 is divided into detection beam, high beam and low beam according to the angle from back to front; the detection beam passes through the flat cover After being reflected by the surface 31, it is irradiated onto the photodetector 33 arranged above the flat cover surface 31; the high beam is reflected by the parabolic cover surface 32 to form a high illumination ray.

[0042] Compared with the prior art, the advantages of the vehicle light source and its manufacturing process of the present invention are:

[0043] Distributed collection of the same...

Embodiment 2

[0077] Such as Figure 8 As shown, the difference from Embodiment 1 is that the dust cleaning assembly also includes a push rod motor 71 and a dust sweeping frame 72; the left and right ends of the headlight cover 5 are provided with a chute; There are two, respectively installed in a chute; said dust sweeping rack 72 is connected with a push rod motor 71 push shafts at one end directly in front of the headlight cover 5, and the other end is connected with another push rod motor 71 push shafts.

[0078] The position that fits the outer surface of the headlight cover 5 on the dust sweeping frame 72 is also provided with bristles 73 to further improve the dust-sweeping effect.

[0079] Clean the outer surface of the headlight cover 5 by sweeping the dust stand 72, compared with the advantage of the dust-beating device:

[0080] Utilizing the push rod motor 71 to control the dust sweeping frame 72 has higher reliability, and the cleaning power of the dust sweeping frame 72 is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com