Small-depth-of-field high-resolution double-telecentric optical lens

An optical lens and high-resolution technology, applied in the field of optical lens, can solve problems such as difficult to obtain Pin needles stably and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

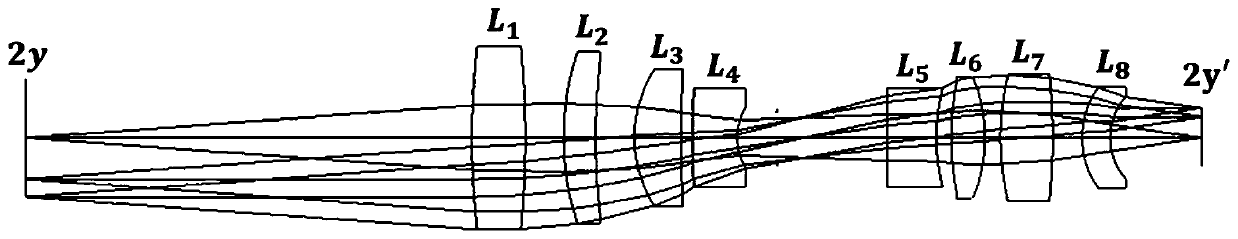

[0041] This embodiment provides a small depth of field high-resolution bi-telecentric optical lens, such as figure 1 As shown, it includes an object-side lens group, an aperture stop and an image-side lens group. The object-side lens group and the image-side lens group each have four lenses. The setting method is: along the optical axis direction from the object side 2y to the image side 2y′ followed by biconvex positive lens L 1 , Meniscus positive lens L 2 , Meniscus positive lens L 3 , meniscus negative lens L 4 , aperture stop, meniscus negative lens L 5 , biconvex positive lens L 6 , biconvex positive lens L 7 and meniscus negative lens L 8 .

[0042] Wherein, the refractive index of each lens material above satisfies: 1.601 2 3 4 5 6 7 8 <1.50;

[0043] Among them, n 1 , n 2 , n 3 , n 4 , n 5 , n 6 , n 7 and n 8 followed by biconvex positive lens L 1 , Meniscus positive lens L 2 , Meniscus positive lens L 3 , meniscus negative lens L 4 , meniscus nega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center thickness | aaaaa | aaaaa |

| Center thickness | aaaaa | aaaaa |

| Center thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com