Heavy-load AGV frame lightweight design method based on finite element analysis

A lightweight design and finite element technology, applied in the field of design based on finite element analysis, can solve problems such as large energy consumption, slow speed, and heavy weight, and achieve the effects of high precision automation, high automation, and reduced product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

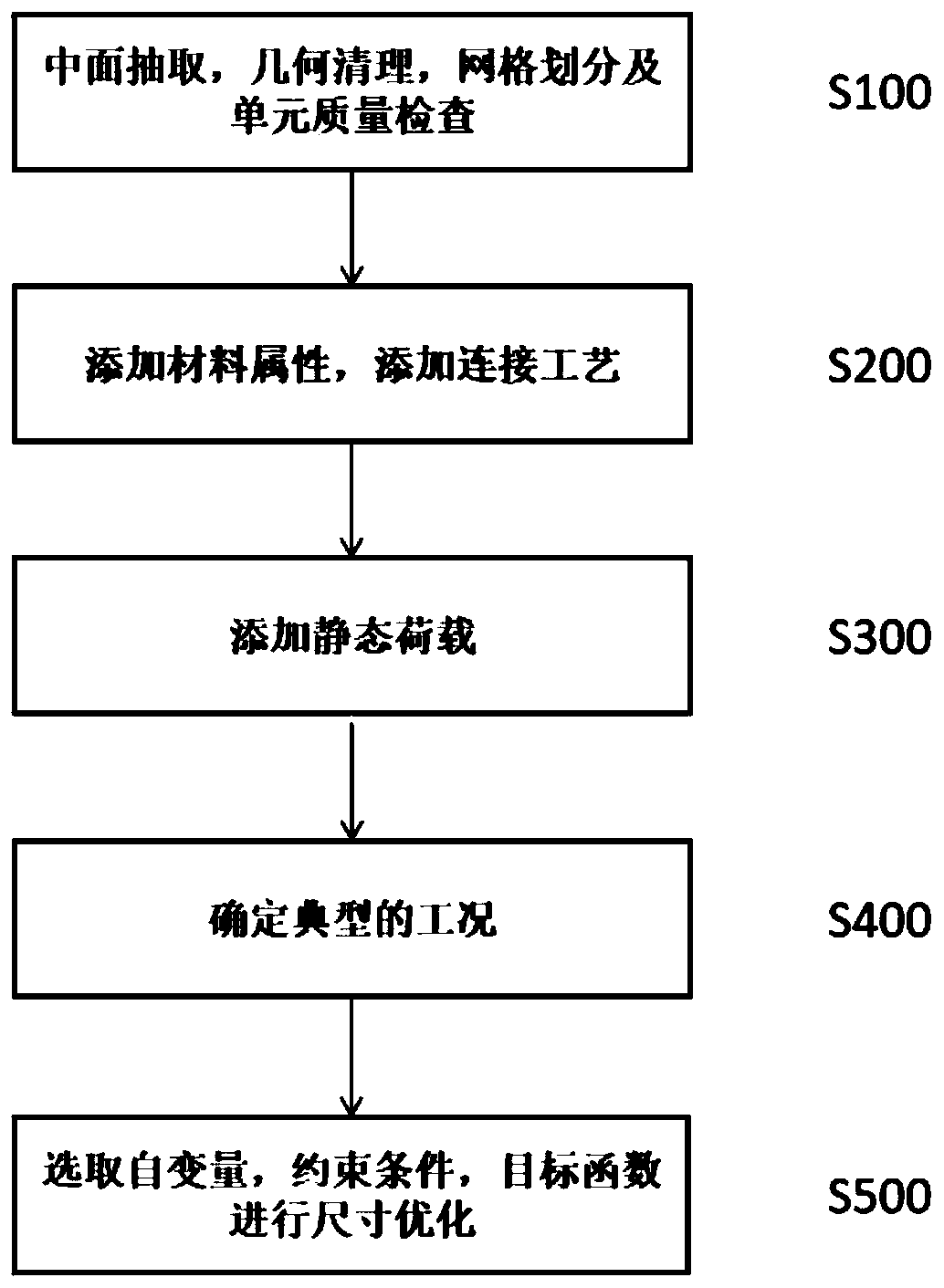

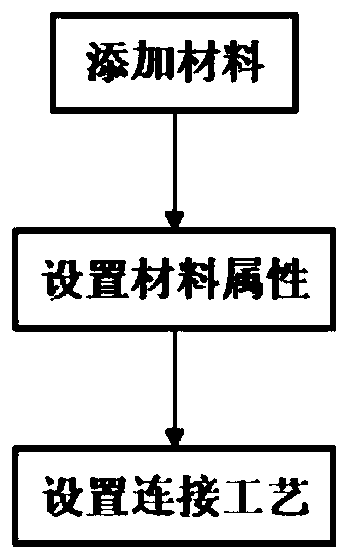

[0024] This embodiment provides a heavy-duty AGV frame lightweight design method based on finite element analysis, the specific steps are as follows:

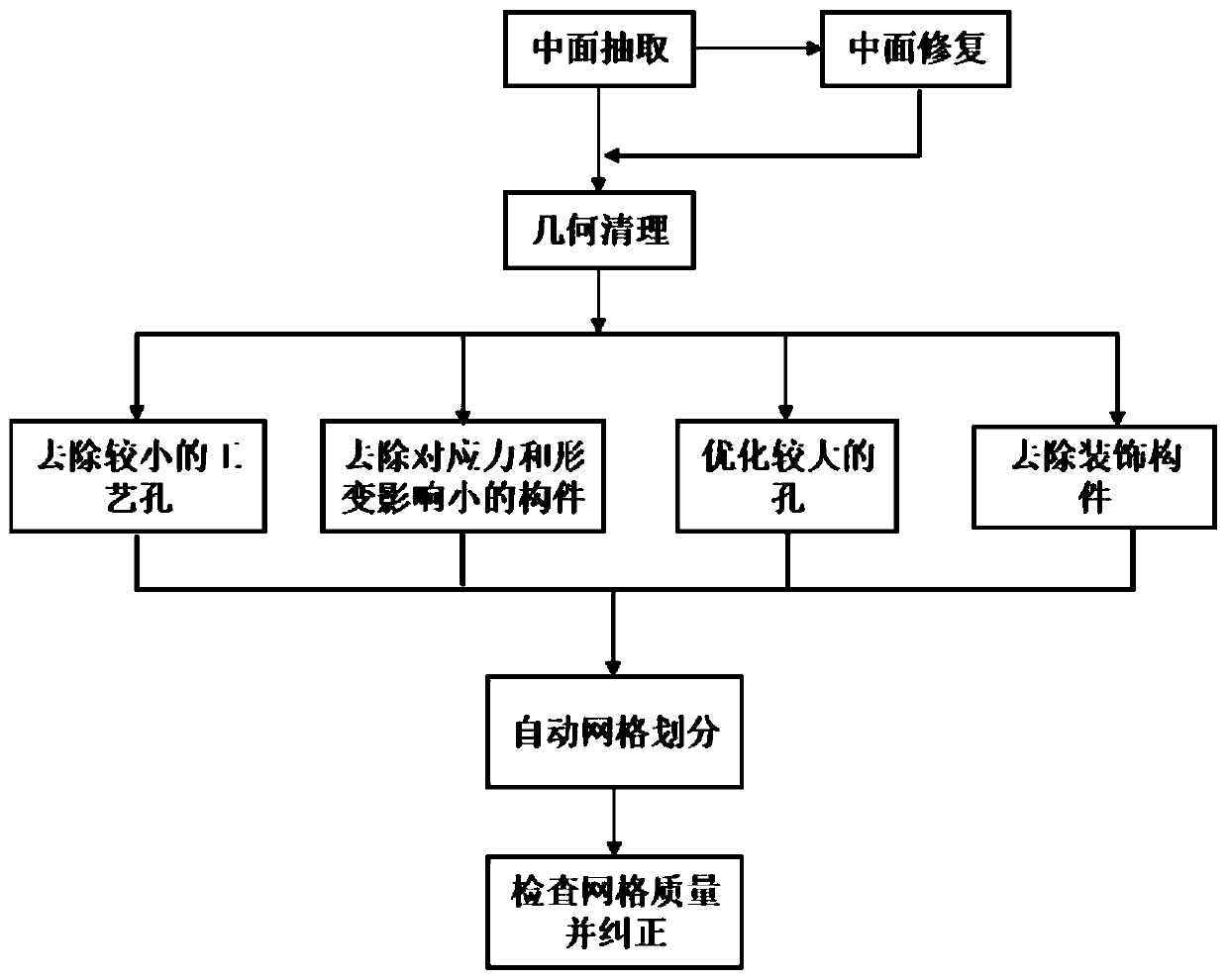

[0025] Step S100, using the mid-surface extraction function panel of the hypermesh software to perform a mid-surface extraction operation on the original frame model. In order to simplify the model and reduce the amount of calculation, necessary geometric cleaning is performed on the model after mid-surface extraction; finally, automatic mesh division and mesh quality inspection are performed on the frame, such as figure 2 shown.

[0026] In step S100, specifically include:

[0027] Step S101, performing mid-plane extraction on the original frame model. Since the length and width of the frame are far greater than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com