Preparation method of LED lamp

A technology of LED lamps and LED lamp beads, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of large time difference, inability to accurately reflect the temperature of the LED chip, and the need for a certain period of time to respond, and achieve a simplified structure The effect of the layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

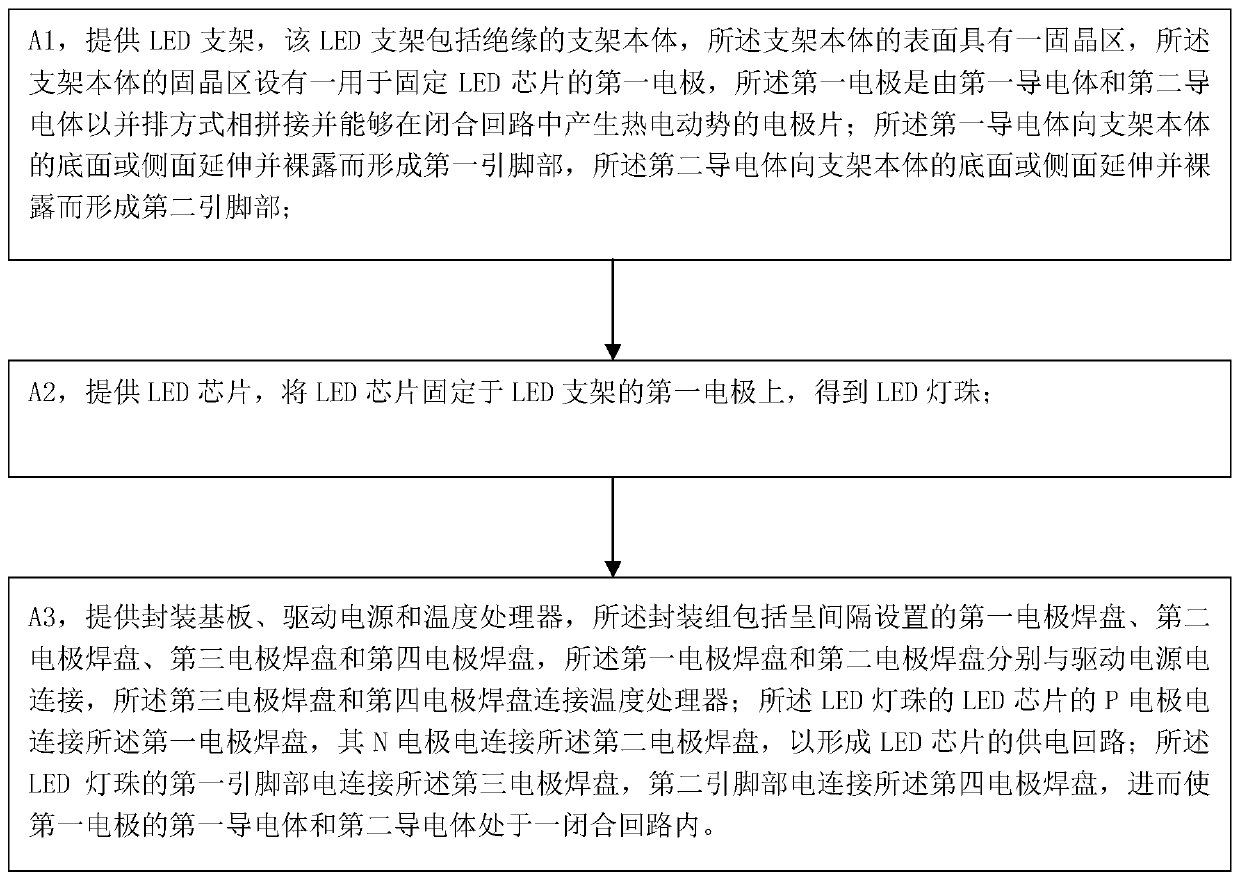

[0033] Reference figure 1 As shown, a method for manufacturing an LED lamp includes the following steps:

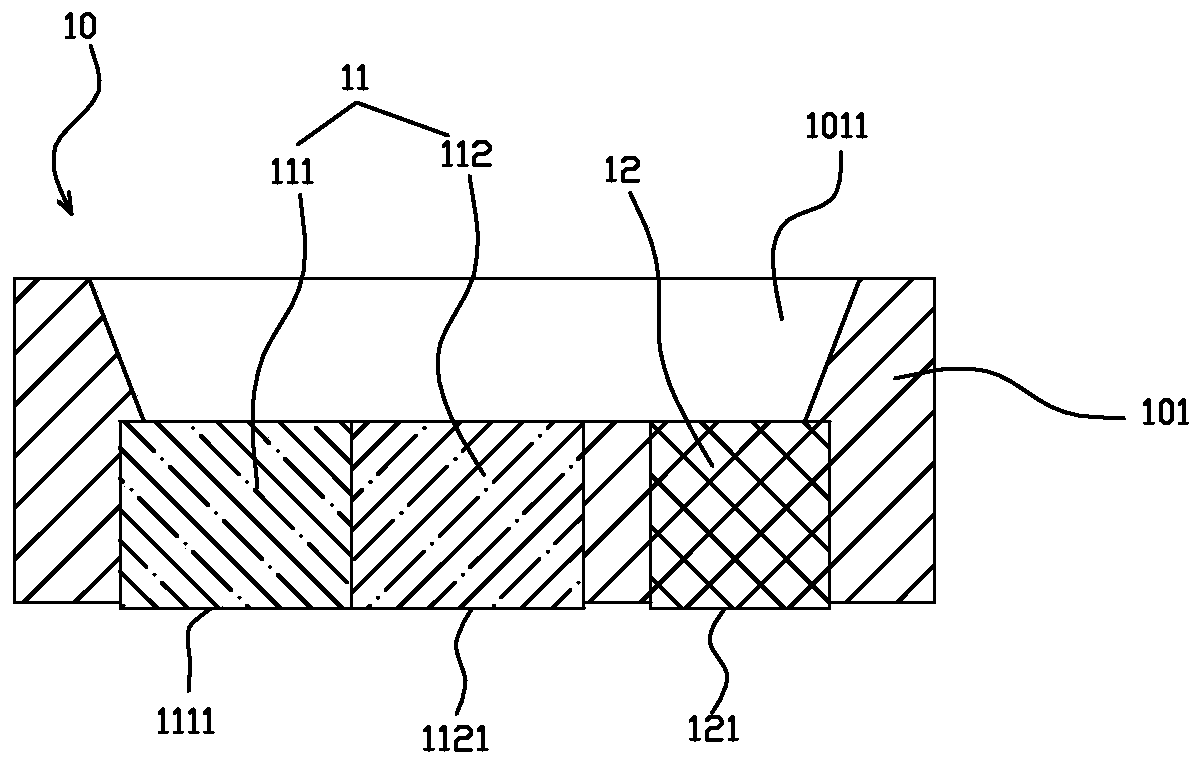

[0034] A1, provide LED bracket, refer to figure 2 , image 3 As shown, the LED stent includes an insulated stent body, the surface of the stent body has a die-bonding area, and the die-attachment area of the stent body is provided with a first electrode for fixing the LED chip. The first electrode is An electrode sheet that is spliced side by side by a first electrical conductor and a second electrical conductor and can generate thermoelectromotive force in a closed loop; the first electrical conductor faces the bottom surface of the support body (in other embodiments, it may also be a side surface) Extending and being exposed to form a first lead part, and the second conductive body extends to the bottom surface (or a side surface in other embodiments) of the support body and being exposed to form a second lead part.

[0035] Specifically, the die-bonding zone of this st...

Embodiment 2

[0054] The preparation method of the LED lamp provided in this embodiment is roughly the same as the preparation method of the first embodiment, the difference is:

[0055] In step A1, refer to Figure 7 As shown, the die bonding area of the holder body 101 is provided with a second electrode 12 and a third electrode 13 as positive and negative electrodes, and the second electrode 12 faces the bottom surface of the holder body 101 (in other embodiments, it may also It is a side surface) extending and exposed to form a third pin portion 121, and the third electrode 13 extends to the bottom surface (or a side surface in other embodiments) of the holder body 101 and is exposed to form a fourth pin portion 131. The first electrode 11 only serves as an electrode for fixing the LED chip 21.

[0056] Meanwhile, the first electrical conductor 111 of the first electrode 11 is a nickel-chromium alloy, and the second electrical conductor 112 is a copper-nickel alloy. After the first electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com