Efficient heat dissipation mechanism of inverter device

A technology of a heat dissipation mechanism and an inverter, which is applied in the output power conversion device, the structural parts of the conversion equipment, and the modification of power electronics, etc. Efficient cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

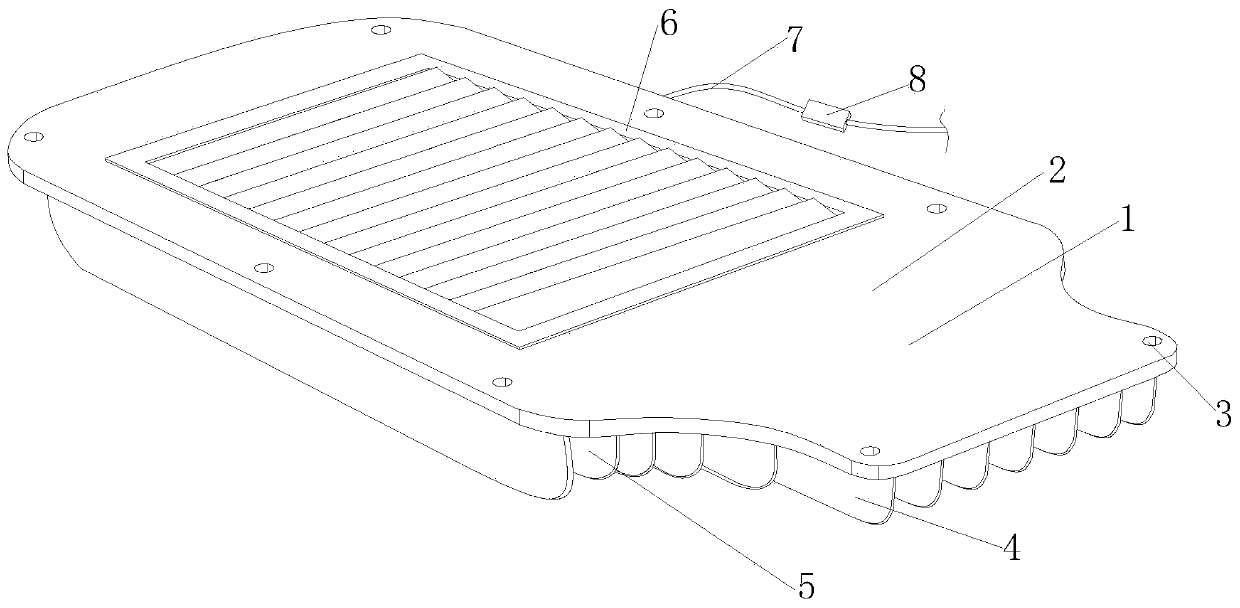

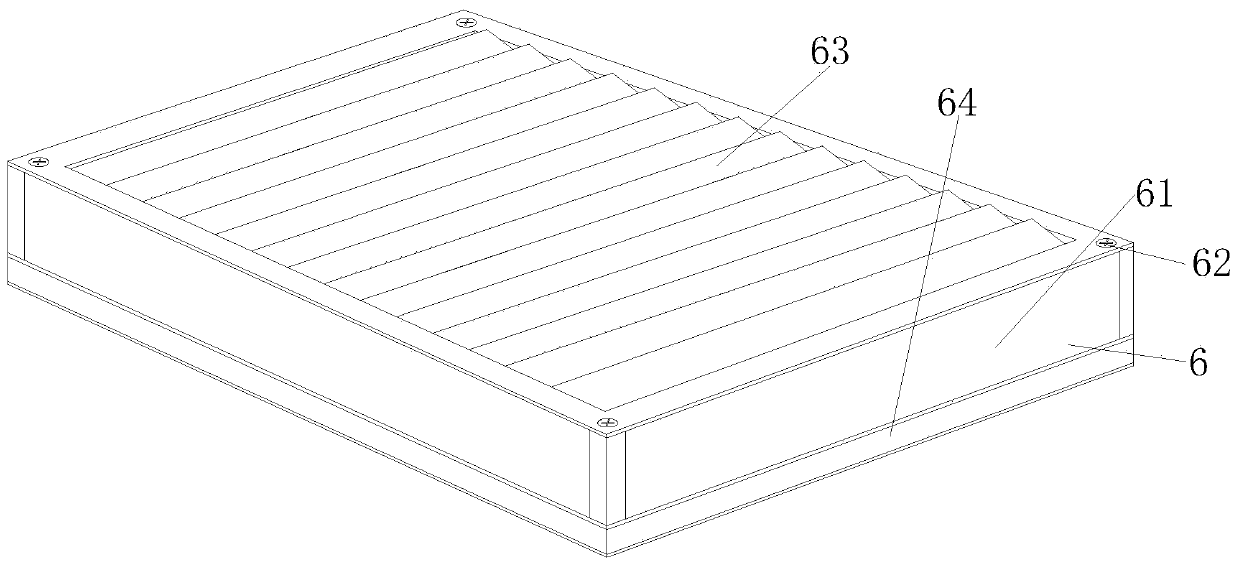

[0030] see figure 1 , a high-efficiency heat dissipation mechanism for an inverter device of the present invention, the heat dissipation body 1 includes a main frame 2, a fixing hole 3, a long heat conduction sheet 4, a short heat conduction sheet 5, an air cooling structure 6, a power cord 7 and a control switch 8, There are eight fixing holes 3 at equal distances on the outside of the main frame 2. Long heat conducting fins 4 are vertically embedded in the middle side of the bottom of the main frame 2. Short heat conducting fins 5 are vertically embedded on the left and right sides of the bottom of the main frame 2. The side is embedded with an air-cooling structure 6, and the left side of the rear of the main frame 2 is provided with a power cord 7, and a control switch 8 is installed on the inner side of the power cord 7. The air-cooling structure 6 can quickly dissipate heat from the inverter, and can effectively block External dust enters the inverter.

[0031] see fi...

Embodiment 2

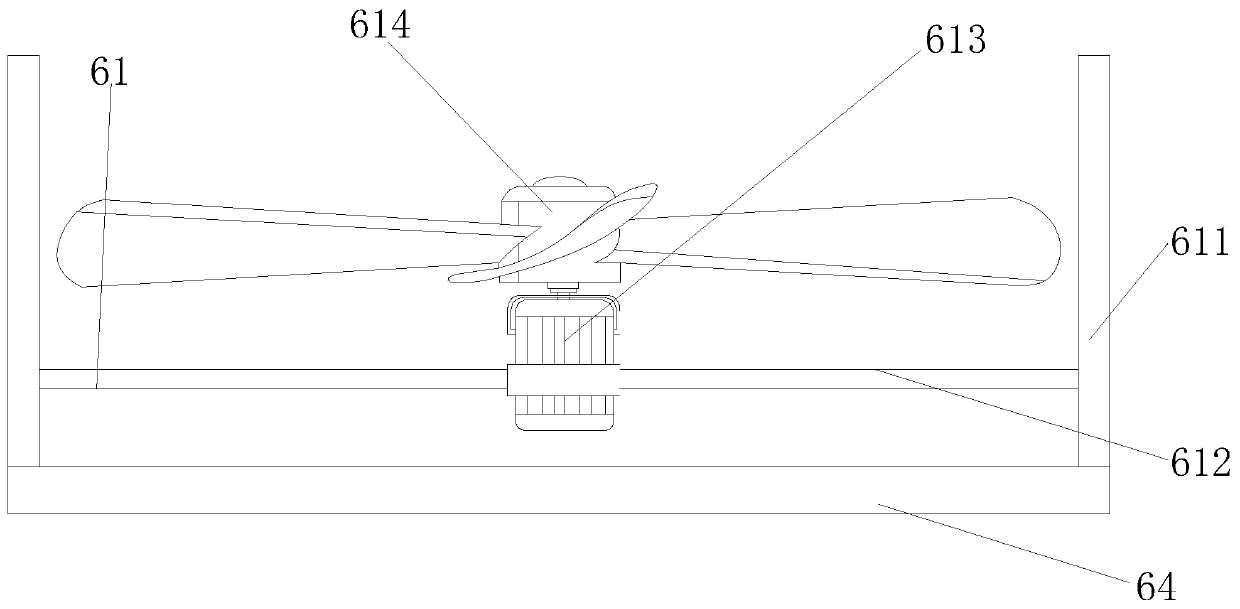

[0038] In the high-efficiency heat dissipation mechanism of the inverter device of the present invention, there are fourteen sheets 6331 in total, and the fourteen sheets 6331 are equidistantly arranged inside the rectangular frame sheet 631, and the air flow is changed by the fourteen sheets 6331 According to the size of the passage, the rotating shaft rod 6332 is inserted into the inner side of the rotating hole 6322 and connected to it in rotation. The sheet body 6331 is rotated through the rotating shaft rod 6332. The rectangular block 6333 is inserted into the inner side of the card slot 6324 and engaged with it. The cooperation between the grooves 6324 changes the rotation angle of the sheet body 6331, the brush 6334 at the bottom of the sheet body 6331 is in contact with the top of the other sheet body 6331, and the brush 6334 removes the dust on the other sheet body 6331 when the sheet body 6331 rotates. Brush down.

[0039] The present invention provides a high-effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com