Manufacturing method of tent support

A manufacturing method and tent technology, applied in tents/canopies, building types, buildings, etc., can solve the problems of weak adhesion, rusted pipe body, uneven distribution of glue, etc. Longer life, uniform and stable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

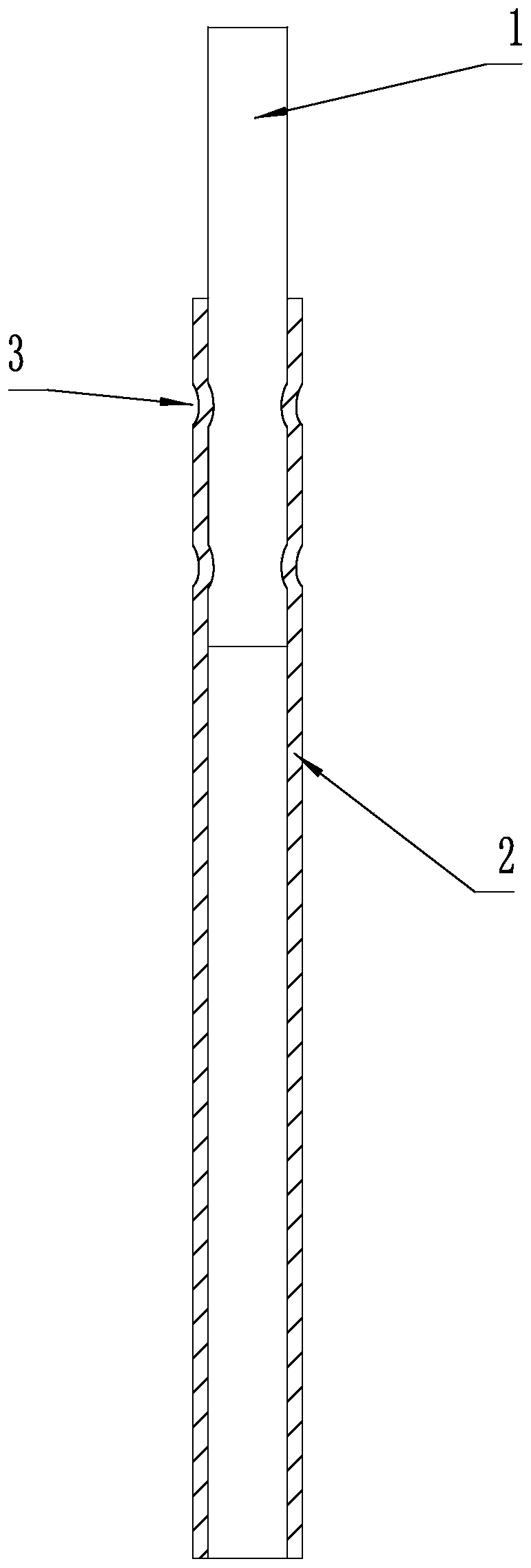

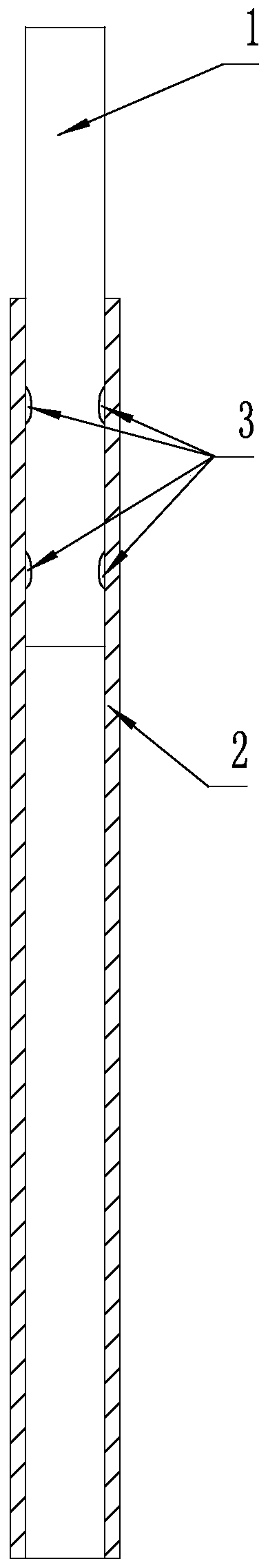

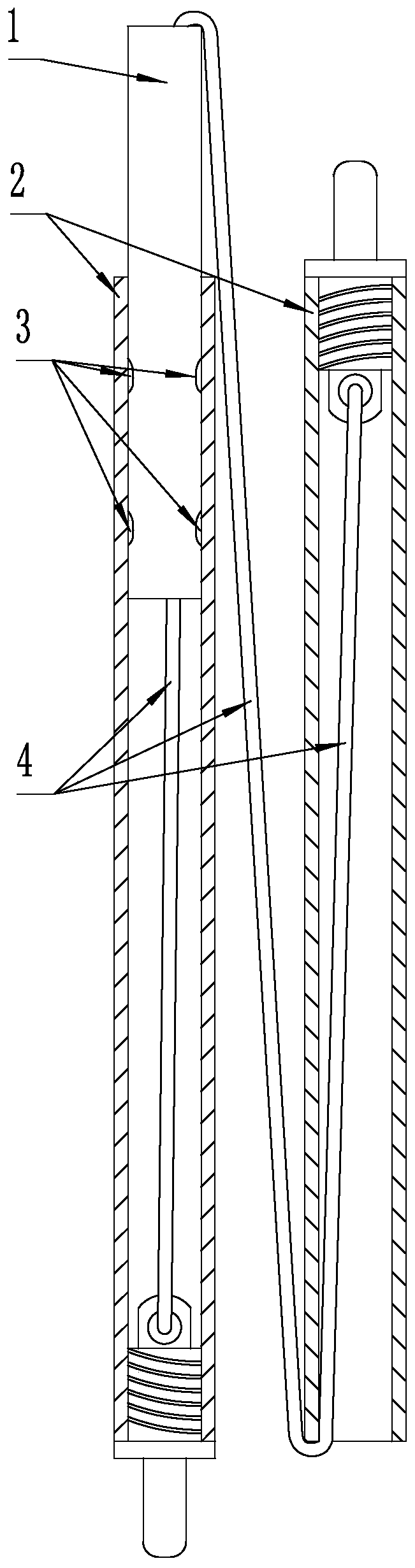

[0036] Such as figure 2 , image 3 As shown, a tent support includes multiple sets of folding poles, and two adjacent groups of folding poles are movably socketed with each other, and the two are detachable, that is, the inner tube 1 of the former folding pole is movably socketed on the latter group of folding poles. inside the outer tube 2; each group of foldable struts includes two fixedly socketed tube bodies, and according to the relative positional relationship between the two tube bodies after they are set, the tube body is divided into inner tube 1 and outer tube 2, and the inner tube is 1 set Set in the lumen of the outer tube 2.

[0037] When folding, separate the adjacent two groups of folded poles that are movable sockets, and the disassembly and folding of the whole tent support can be realized; Assembly of the tent frame.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com