Automobile anti-collision beam machining device

A technology of processing devices and anti-collision beams, which is applied to metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of difficult cleaning, drilling debris falling on the work table and working environment, and reduce the cleaning cost. Difficulty, the effect of ensuring a fixed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

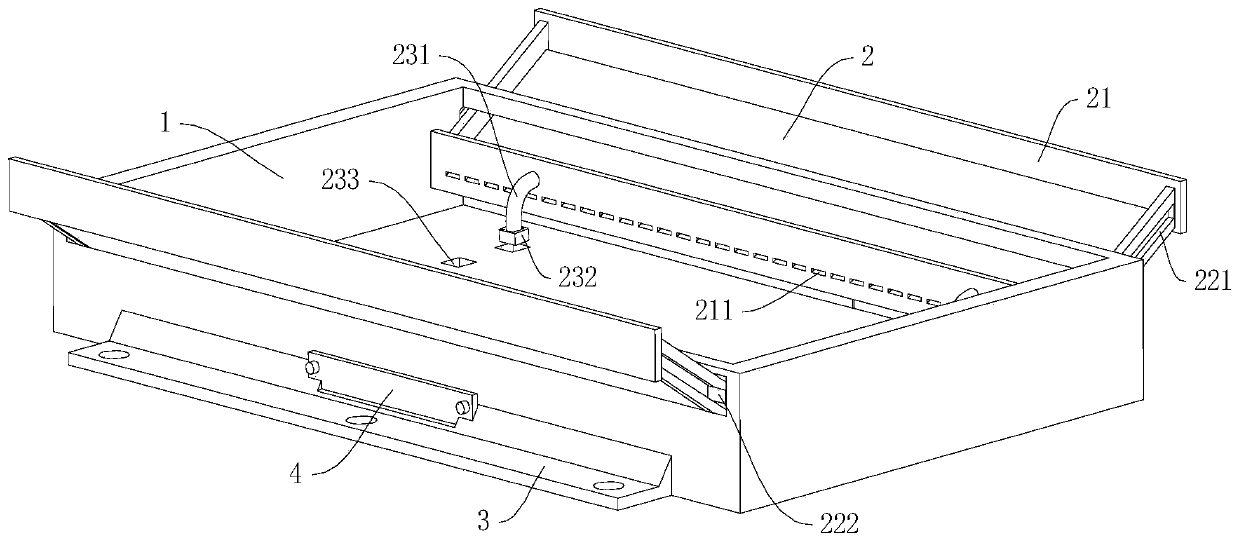

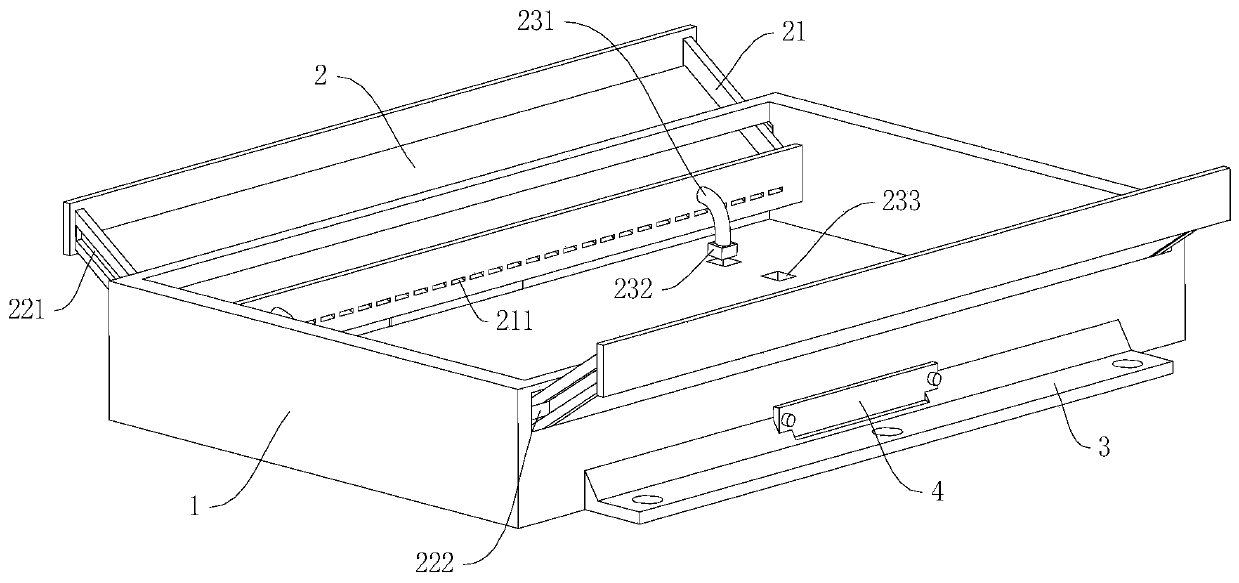

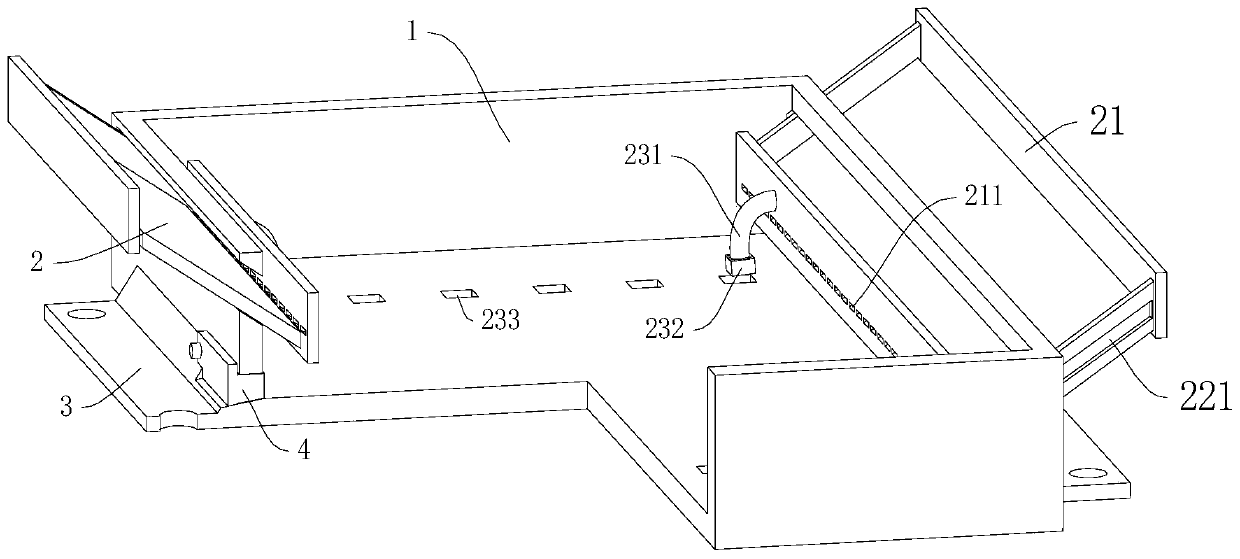

[0022] It includes a bottom container 1 for storing waste generated during the processing of automobile anti-collision beams. The interior of the bottom container 1 is hollow and it is fixed on the ground through a mounting plate 3. The side of the bottom container 1 is equipped with an outer protection against splashing. Plate 2, the projection of the protective surface formed by the outer guard plate 2 and the bottom container box 1 covers the entire automobile anti-collision beam processing device, and the outer guard plate 2 is covered with a coaming plate 21 that increases the depth of its inner cavity, and the outer guard plate The coaming plate 21 on the 2 is vertically installed and surrounds the outside of the outer guard plate 2.

[0023] When drilling the anti-collision beams of automobiles, etc., the bottom container 1 is installed on the bottom of the processing device in advance, and the cooling water or slag generated during the processing is collected in the inn...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that the protection range formed by the outer guard plate 2 and the bottom container box 1 is adapted to the protection needs of different sizes of automobile anti-collision beam processing devices:

[0026] A chute 221 is provided on the coaming plate 21 located on the left and right sides of the outer guard plate 2, and a guide plate 222 connected to the bottom container box 1 is slid in the chute 221, and the outer guard plate 2 slides relative to the bottom container box 1, and The connecting pipe 231, the block 232 and the slot 233 are connected between the outer guard plate 2 and the bottom container 1 to make the two relatively fixed. The connecting pipe 231 is connected to the outer guard plate 2 or the bottom container 1, and the block 232 is far One end of the connecting pipe 231 is fixed in the slot 233;

[0027] There are several draw-in slots 233 and they are uniformly distributed at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com