Device and method for detecting falling of coal conveying belt patrolling person

A detection device and belt technology, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve problems such as complex distribution of equipment, endangering personal safety of personnel, and hazards to the safe operation of equipment along the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

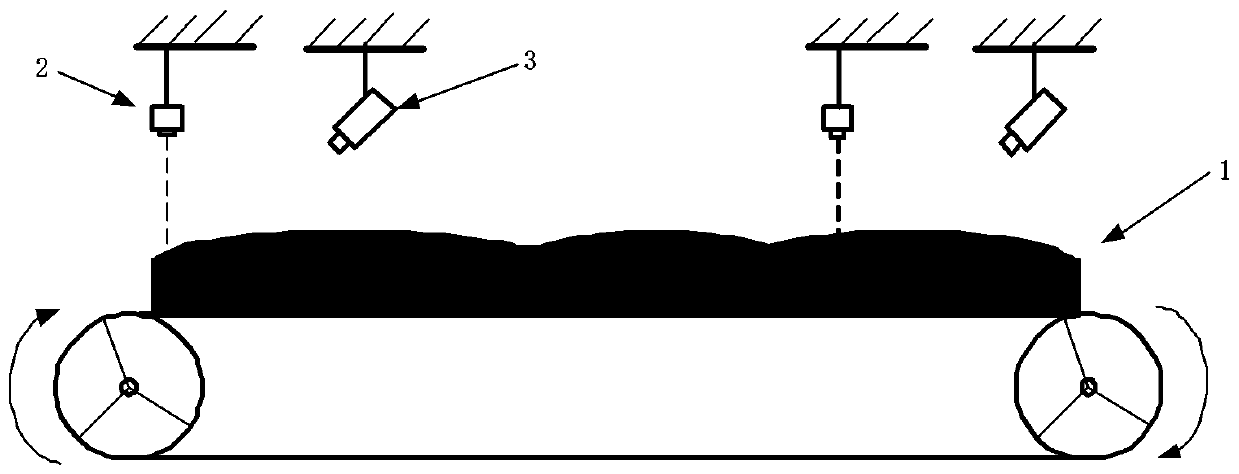

[0026] The fall detection device for inspection personnel on the coal conveying belt includes a set of signal acquisition devices respectively located at the head and tail of the belt 1, and also includes a drop detection controller for belt inspection personnel for signal transmission with the signal acquisition device; among them, the signal acquisition device Including an inline laser 2 and a digital camera 3; the inline laser 2 is connected to the belt patrol personnel drop detection controller through a control signal line; the digital camera 3 is connected to the belt patrol personnel drop detection controller Connect via Ethernet cable.

Embodiment 2

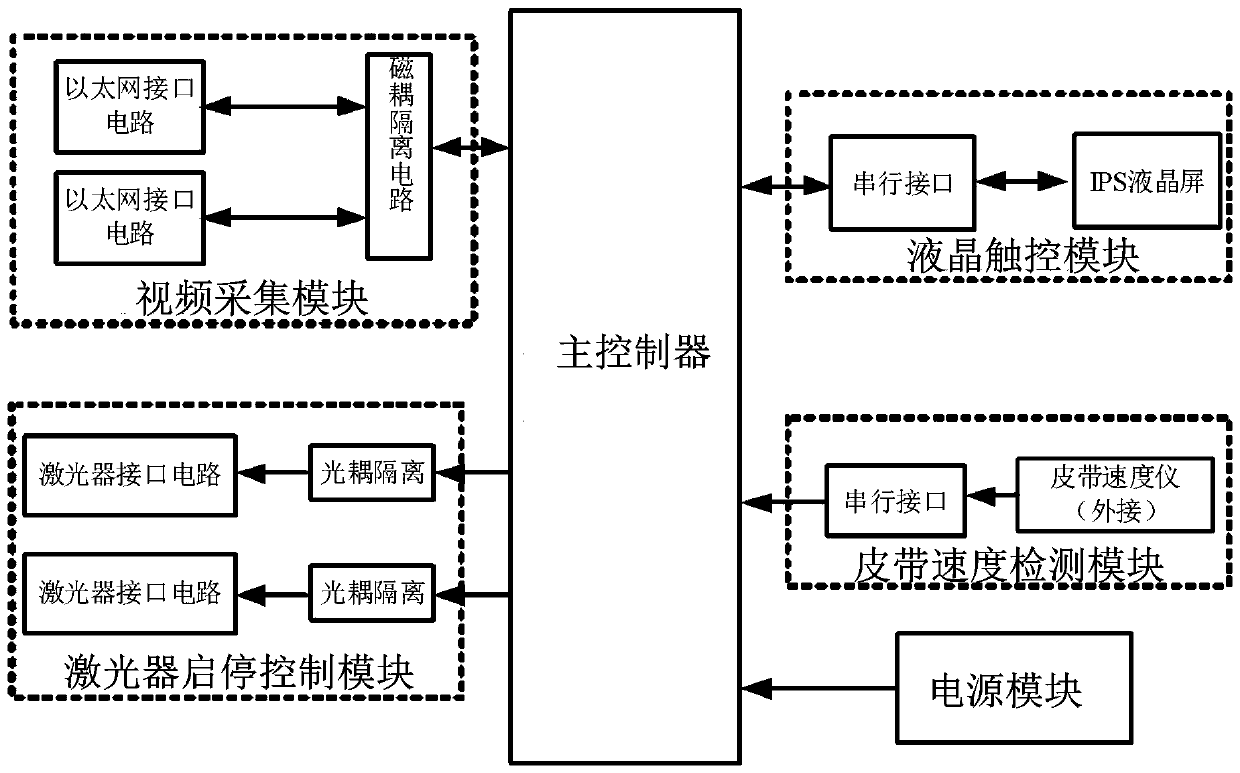

[0028] On the basis of Embodiment 1, the fall detection controller of the belt inspection personnel includes a main controller and a video acquisition module respectively connected to the main controller, a laser start-stop control module, a liquid crystal touch module, a belt speed detection module and The power supply module; the inline laser 2 and the digital camera 3 are both connected to the main controller; the belt speed detection module is connected to an external coal conveyor belt speed detector. The digital camera 3 is sequentially connected to the main controller through the Ethernet interface circuit and the magnetic couple isolation circuit; the linear laser 2 is sequentially connected to the main controller through the laser interface circuit and the optocoupler isolation circuit; the liquid crystal touch module and the external coal delivery The belt speed detectors are all connected to the main controller through the serial interface. The liquid crystal touch ...

Embodiment 3

[0031] A machine vision and laser-based method for detecting the fall of inspection personnel on a coal conveyor belt, using the above-mentioned drop detection device for inspection personnel on a coal conveyor belt, the specific detection method is as follows:

[0032] 1) Install a set of signal acquisition devices at 1.5m-2.0m above the head and tail of belt 1;

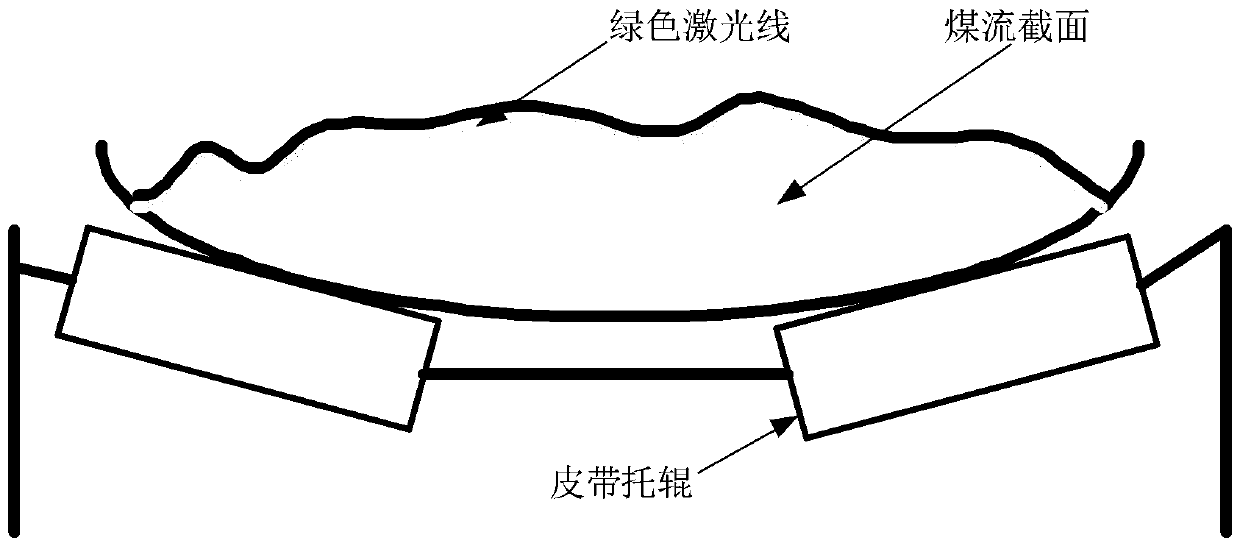

[0033] Among them, the inline laser 2 is vertically installed above the belt 1, and its laser vertical line is vertically projected on the surface of the belt 1; the angle between the lens axis of the digital camera 3 and the laser vertical line of the inline laser 2 is at 45°- Between 75°, it is used to collect the image of the belt 1; the inline laser 2 is a 150mw green laser inline laser 21;

[0034] 2) At time T0, the digital camera 3 installed at the head of belt 1 transmits the collected image of belt 1 to the drop detection controller of the belt inspection personnel; at time T1, the coal material originally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com