Special lifting appliance for railway vehicle floor frame

A technology for rail vehicles and spreaders, which is applied to the underframe, railway car body parts, load hanging components, etc., can solve the problems of difficult quality assurance, inability to pull out the suspending rope, safety problems, etc., so as to avoid operation quality defects, The effect of reducing weight and reducing business costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

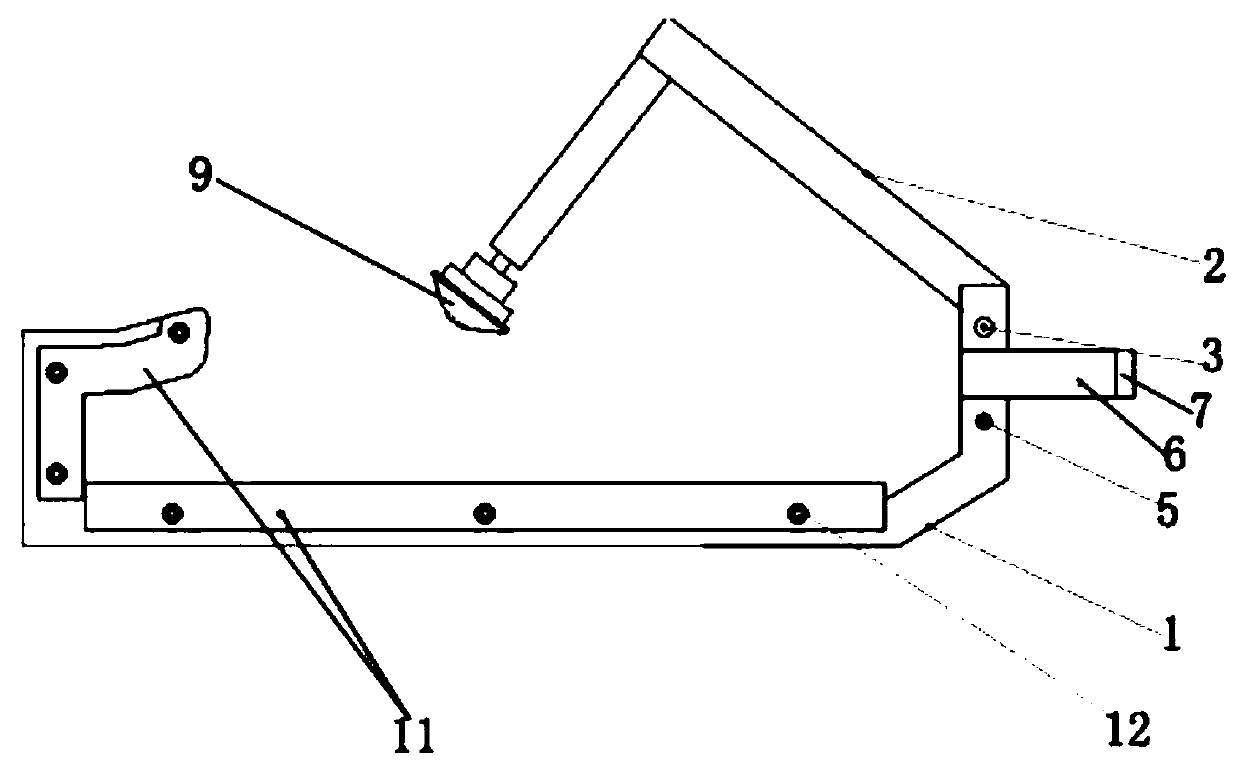

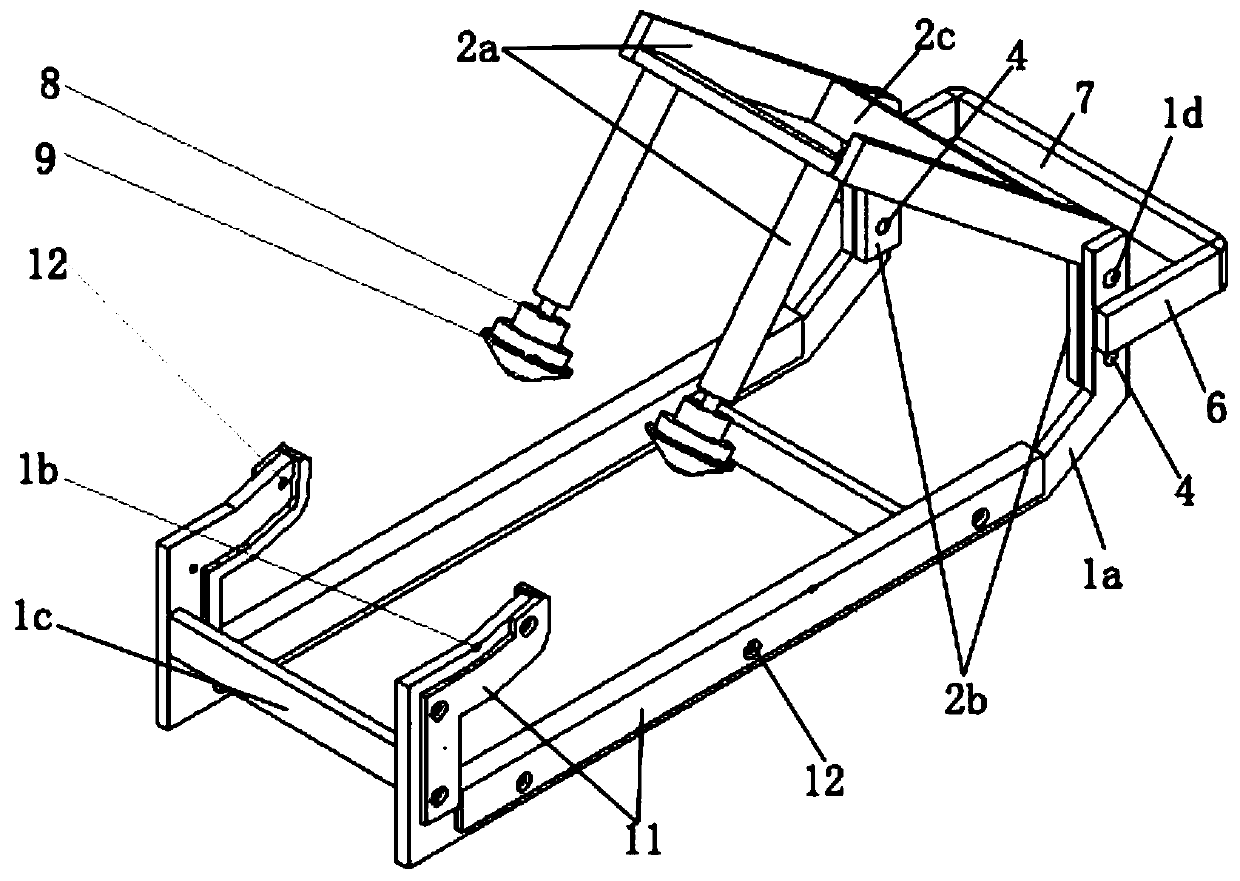

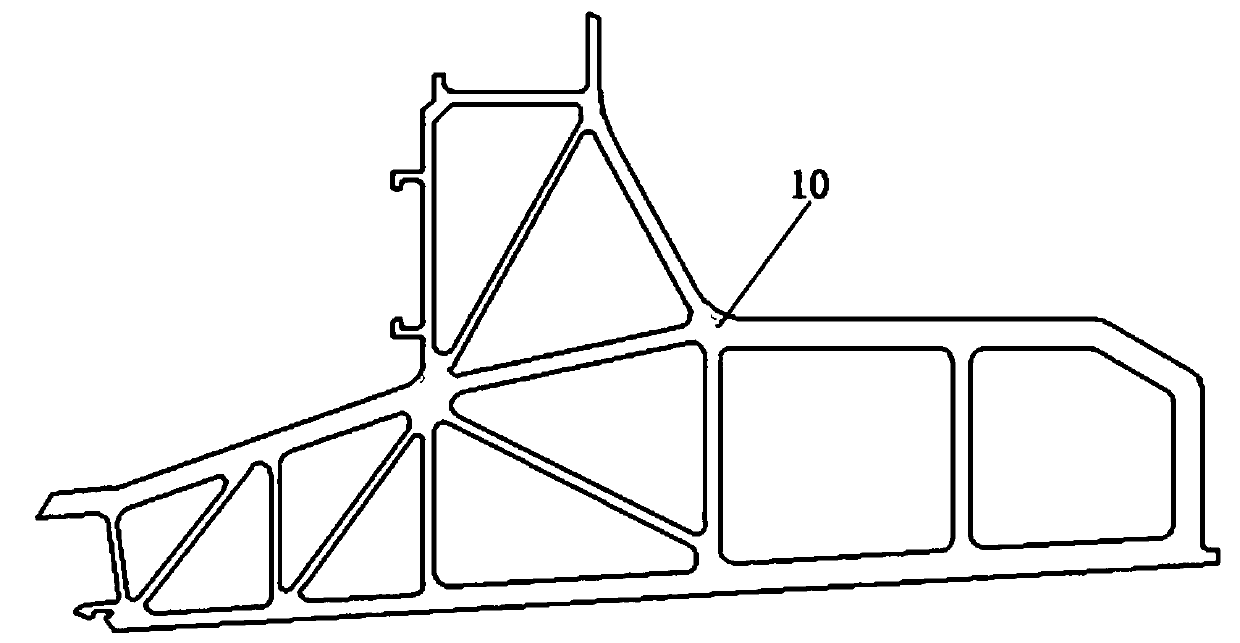

[0022] Example: see figure 1 , figure 2 and image 3 , in the figure, 1-spreader frame, 2-spreader buckle, 3-rotating shaft, 4-fixing hole, 5-fixing pin, 6-hanging rod, 7-cross bar, 8-clip ring, 9-ball nylon block, 10-edge beam, 11-U-shaped rubber block, 12-countersunk head screw;

[0023] 1a -U-shaped beam, 1b-inner buckle beam, 1c-first connecting rod, 1d-hinge hole;

[0024] 2a-right angle beam, 2b-connecting beam, 2c-second connecting rod.

[0025] The special spreader for the side beam of the rail vehicle floor includes a spreader frame and a spreader buckle. The spreader frame has a U-shaped structure. One end of the spreader frame is hinged to one end of the spreader buckle through a rotating shaft, and is fixed and limited by a fixing device. The other end of the spreader frame is in the shape of an inner buckle; the spreader frame includes a U-shaped beam, an inner buckle beam and a first connecting rod, one end of the U-shaped beam is provided with a hinged hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com