Speed limiting device for stacker

A speed limiting device and stacker technology, applied in the direction of lifting device, lifting equipment safety device, etc., can solve the problems of the rapid drop of the lifting platform, the stacker has no speed limit device, and the collision, etc., to avoid collision and easy to use. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

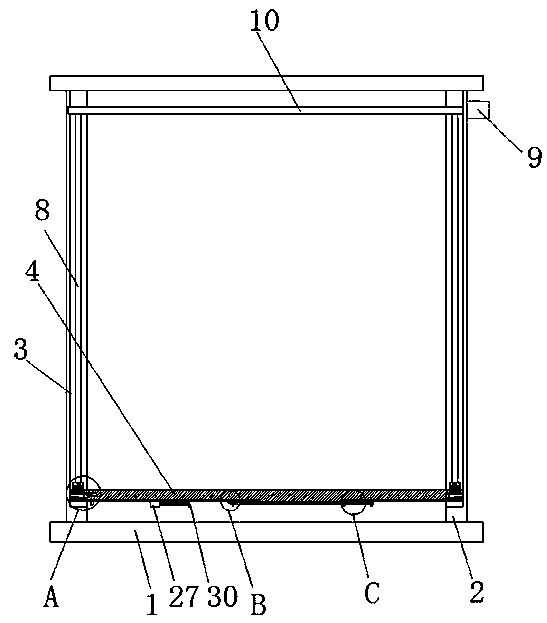

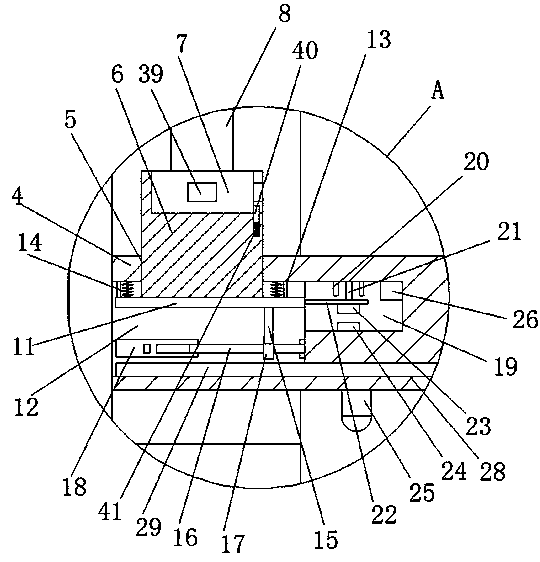

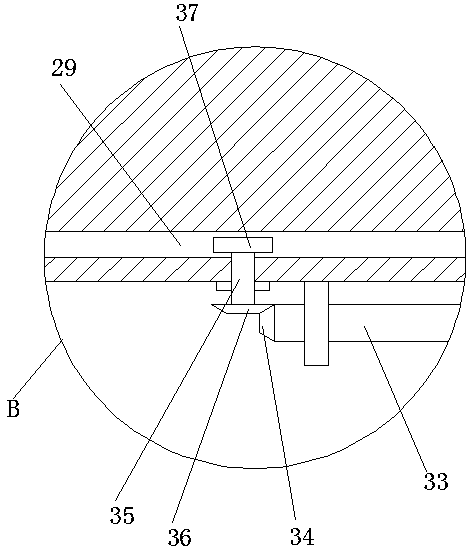

[0029] refer to Figure 1-5 , a speed limiting device for a stacker, comprising a bottom plate 1, two vertical plates 2 are fixedly installed on the top of the bottom plate 1, and a chute 3 is provided on the side where the two vertical plates 2 are close to each other, and the two chute 3 The same lifting platform 4 is slidingly installed inside, and the top of the lifting platform 4 is provided with two sliding holes 5, and a sliding plate 6 is slidingly installed in the two sliding holes 5, and a mounting block 7 is installed on the top of the two sliding plates 6. The tops of each mounting block 7 are fixedly connected with one end of a steel wire rope 8, and the other ends of the two steel wire ropes 8 are fixedly connected with the same drum 10, and both sides of the lifting platform 4 are provided with grooves 12, and the two grooves 12 The connecting plates 11 are all slidably installed, and the tops of the two connecting plates 11 are fixedly connected with the bottom...

Embodiment 2

[0040] refer to Figure 1-5 , a speed limiting device for a stacker, comprising a bottom plate 1, the top of the bottom plate 1 is fixed with two vertical plates 2 by bolts, the sides of the two vertical plates 2 close to each other are provided with chute 3, the two sliding The same lifting platform 4 is slidably installed in the groove 3, and the top of the lifting platform 4 is provided with two sliding holes 5, and a sliding plate 6 is slidably installed in the two sliding holes 5, and a mounting block 7 is installed on the top of the two sliding plates 6 , the tops of the two mounting blocks 7 are fixedly connected with one end of the steel wire rope 8, and the other ends of the two steel wire ropes 8 are fixedly connected with the same drum 10, and both sides of the lifting platform 4 are provided with grooves 12, two grooves Connecting plates 11 are all slidably installed in 12, and the tops of the two connecting plates 11 are fixedly connected with the bottoms of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com