Super heat conductive grain dryer

A dryer and superconducting heat technology are applied in the direction of drying and preserving seeds, which can solve the problems of easy mildew and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

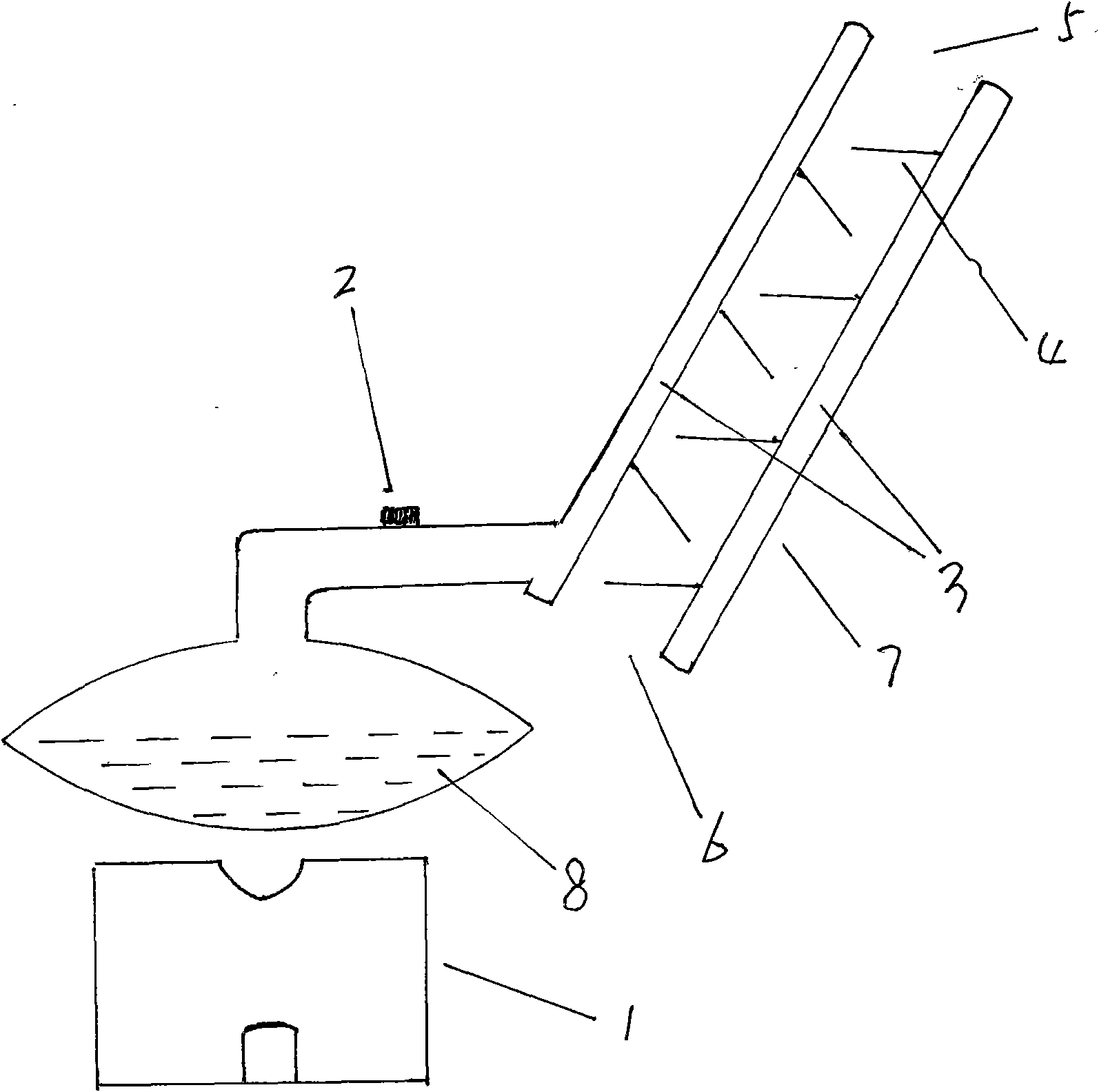

[0007] The present invention will be further described below in conjunction with drawings and embodiments.

[0008] In the figure, the heat source receiver 9 is connected to the lower part of the dryer 7 through a pipeline, and connected to the interlayer of the interlayer pipe 3 after being connected, and a plurality of restrictor plates 4 are installed on the inner wall of the dryer 7 to limit the downward flow rate of the grain , make the dryer 7 form an angle of 60° with the ground, add the superconducting heat material 8 to the heat source receiver 9 by adding the superconducting heat material vacuum port 2, and use the vacuum pump to evacuate all the spaces in the interlayer pipe 3 and the pipe into a vacuum , seal and add superconducting heat-conducting material to evacuate the port 2, put the grain with higher water content from the grain inlet 5, and after being blocked by the flow limiting plate 4 for many times, the moisture in the grain will come from the grain inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com