Sectional Steel and Concrete Combined Underground Diaphragm Wall Structure and Its Construction Method

An underground diaphragm wall and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of affecting the development of underground space, loss of use function, waste, etc., to shorten the construction period, reduce the use of concrete, save resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

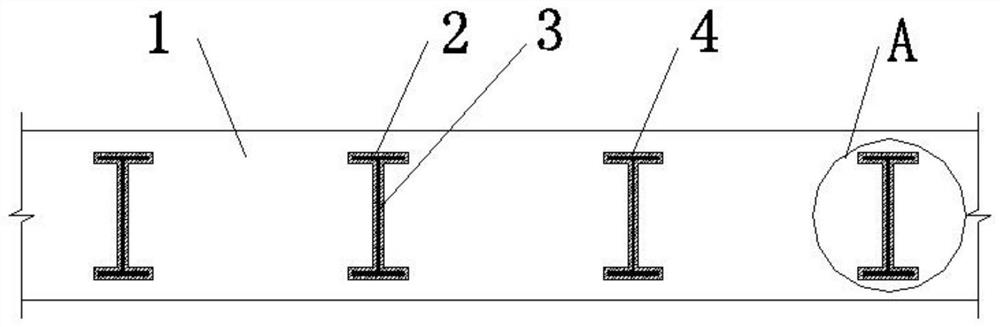

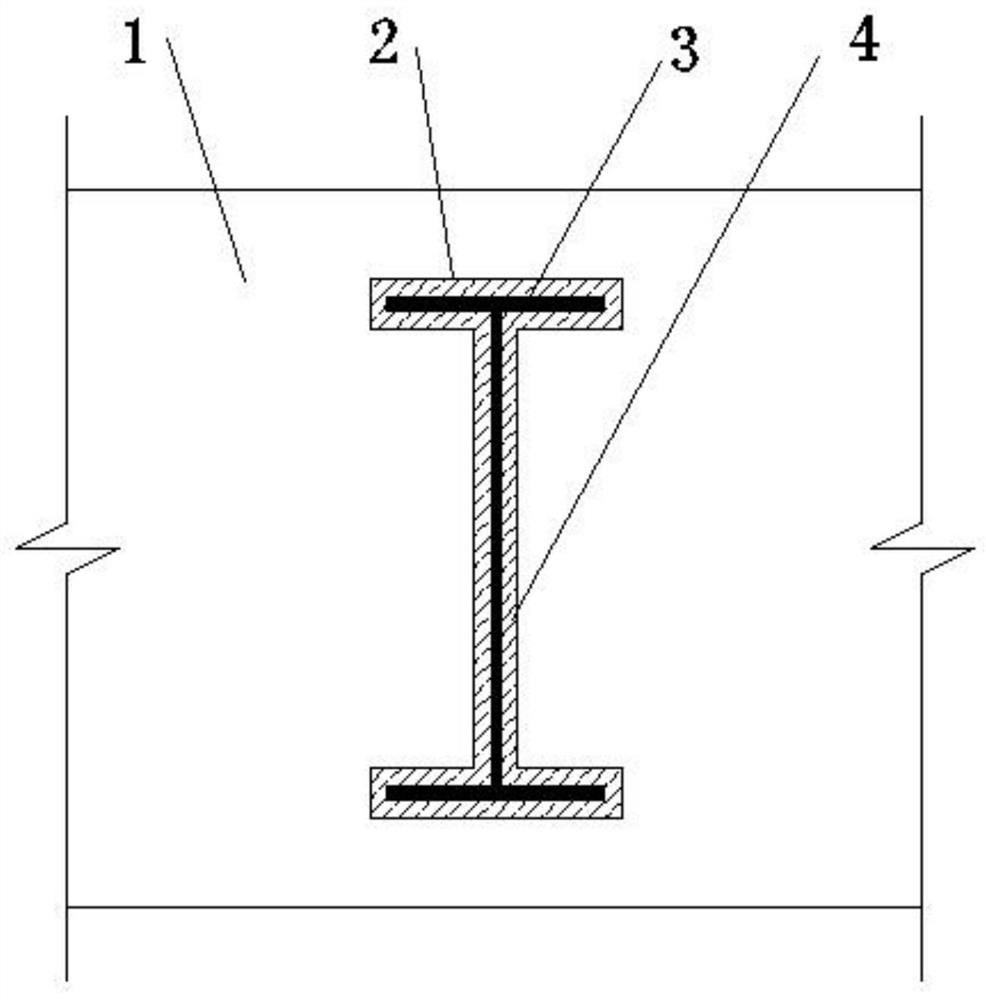

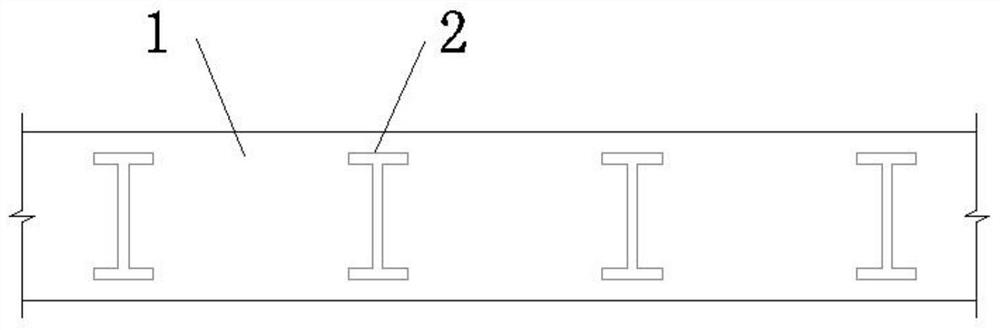

[0030] In order to avoid the waste of the extended part of the underground continuous wall considered in the background technology, and at the same time facilitate the development of deep underground spaces, the present invention particularly invents a recyclable section steel and concrete combined underground continuous wall. The underground continuous wall consists of It consists of three parts: prefabricated underground diaphragm wall with reserved cavity, section steel and grouting and solidification retaining ring. Such as Figure 1-2 As shown, the steel and concrete combined underground diaphragm wall structure defined in the present invention includes a prefabricated underground diaphragm wall body 1 and shaped steel 3, and a group of parallel reserved holes 2 are arranged at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com