A core-filled compensating backing plate and its use method which can be adjusted for misalignment of reserved holes for alignment

A technology of reserved holes and compensation pads, which is applied in the direction of construction and building construction, can solve the problems affecting the safety of the structure, the reserved holes cannot meet the structural standards, etc., and achieve the effect of force stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

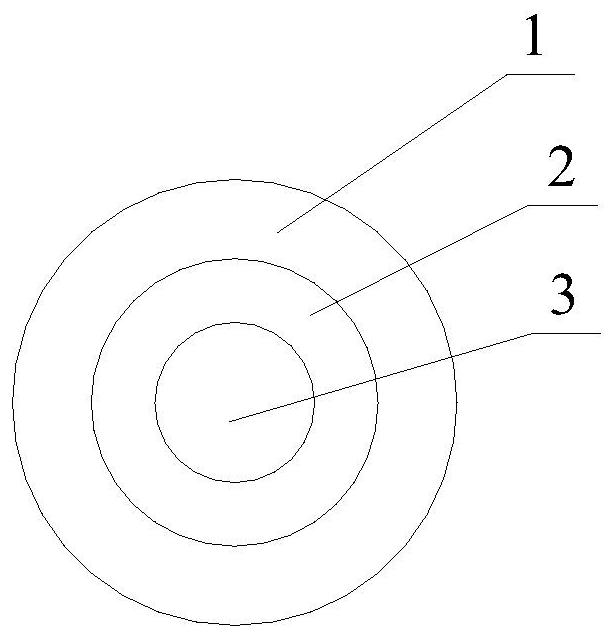

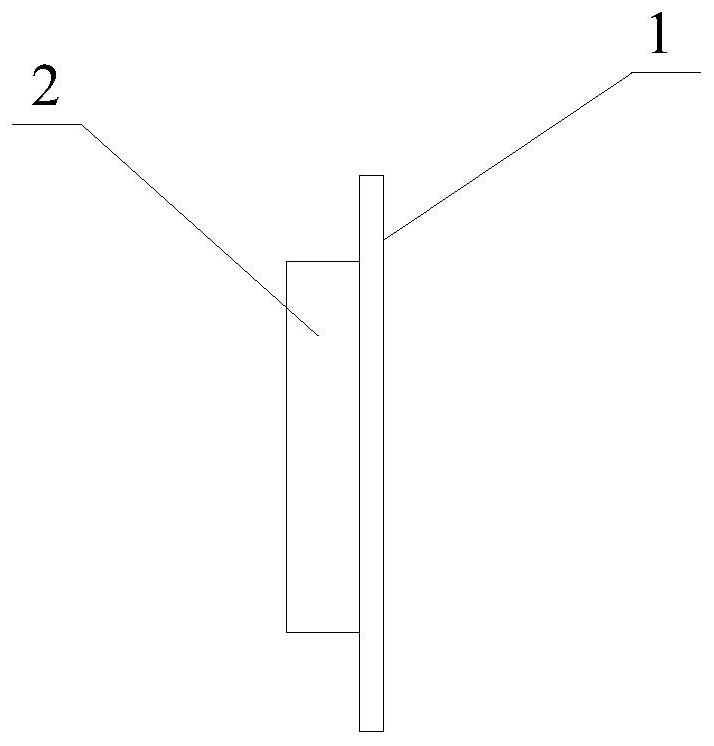

[0025] Embodiment 1: A core-filling compensating backing plate with an adjustable alignment reserved hole misalignment. The compensating backing plate is made into two groups and used together. It includes a fixed plate 1 with a diameter larger than the reserved hole and a core tube 2 whose outer diameter is consistent with the diameter of the reserved hole. The core tube 2 is fixed on the center of one side of the fixed plate 1, and the core tube 2 is hollow. Tubular structure, a circular through hole 3 is provided in the area corresponding to the inner cavity of the core filling tube 2 on the fixing plate 1 .

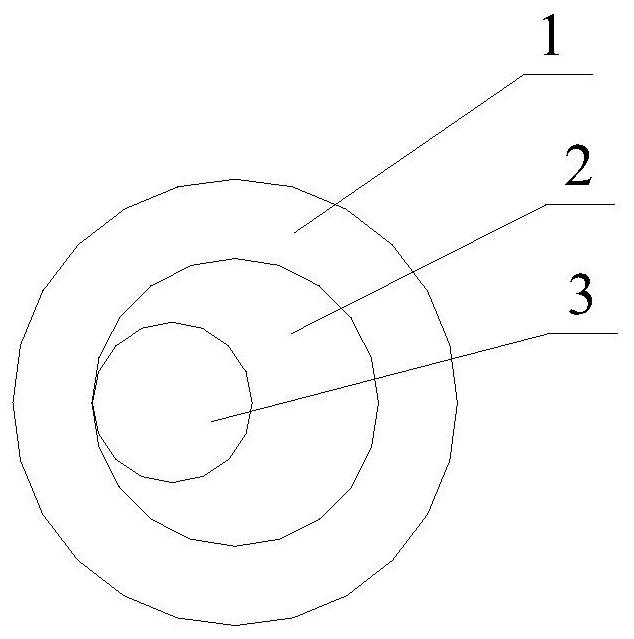

[0026] Wherein the through hole 3 on the fixed plate 1 of one group is positioned at the center in the area corresponding to the inner chamber of the core pipe 2 on the fixed plate 1, and the edge of the through hole 3 on the other set of fixed plate 1 is in line with the center of the core pipe 2. Edges coincide.

[0027] The method of using the above-mentioned alig...

Embodiment 2

[0033] Embodiment 2: An adjustable core-filling compensation backing plate with alignment reserved holes and misalignment. The difference from Example 1 is that the through hole 3 of the fixing plate 1 is elliptical, and only one kind of compensation backing plate needs to be made. Specification.

[0034] The diameter of the elliptical through hole 3 on the fixed plate 1 is smaller than the aperture of the reserved hole, and one of the focal points of the elliptical through hole 3 is located at the center of the area corresponding to the inner cavity of the core tube 2 on the fixed plate 1, and the edge Coincides with the edge of the core tube 2.

[0035] When in use, insert the bolts into the holes of the compensation backing plate at one end, and rotate and adjust the compensation backing plate according to whether there is any error in the position of the reserved hole at the other end, so that the positions of the openings on the compensation backing plates at both ends co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com