Transparent coil plate and manufacturing method thereof, transparent electromagnetic induction plate and display device

A production method and electromagnetic induction technology, which is applied in the fields of electrical digital data processing, instruments, calculations, etc., can solve the problems of high equipment requirements, thick electromagnetic induction plates, and low production efficiency, and achieve simple process equipment requirements and excellent induction magnetic field changes. , Good transparency and visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

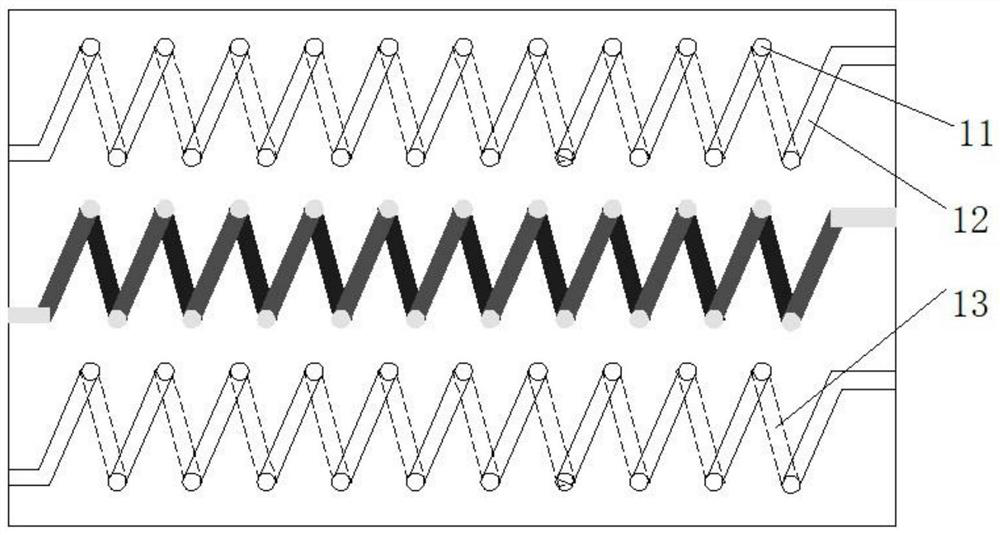

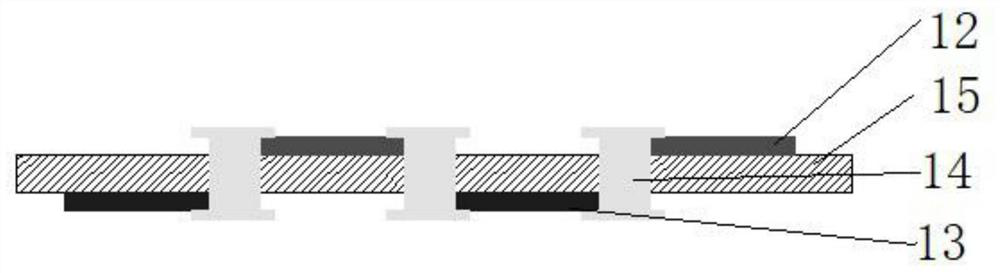

[0045] Figure 13 It is a flow chart of the transparent coil plate manufacturing method in an embodiment provided by the present application, Figure 3-Figure 12 A schematic diagram of the manufacturing process of the transparent coil plate in an embodiment provided by the application, such as Figure 3-13 As shown, the production method includes:

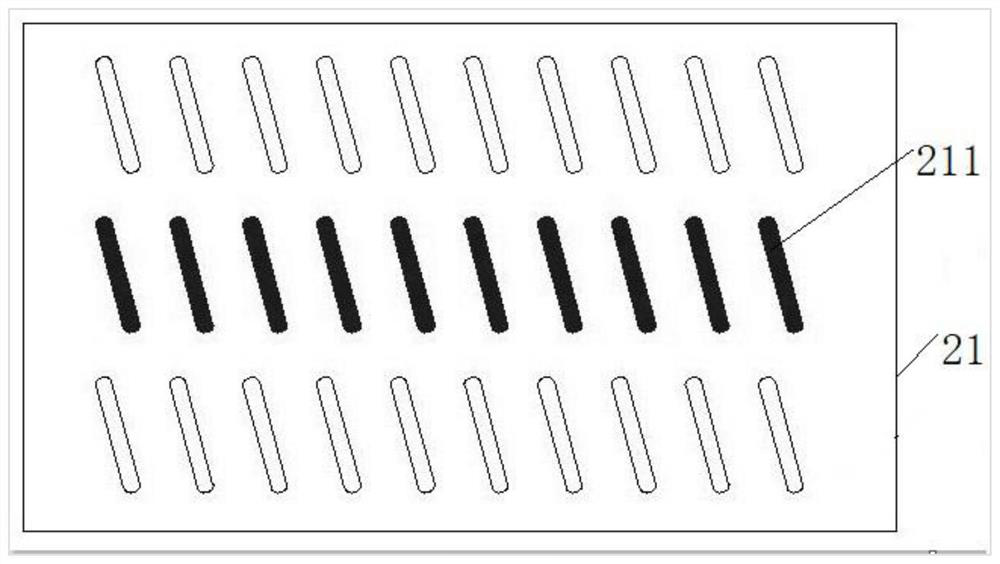

[0046] S101, refer to image 3 and Figure 4 , processing the conductive layer of the transparent conductive substrate 21 into a plurality of first transparent sensing lines 211 arranged in parallel;

[0047] S102, refer to Figure 5 and Image 6 , forming several via holes 221 on the transparent conductive film 22;

[0048] S103, refer to Figure 7 and Figure 8 , paste the transparent conductive film 22 on the transparent conductive substrate 21, wherein the insulating layer 223 of the transparent conductive film 22 is adjacent to the conductive layer of the transparent conductive substrate 21, and the plurality of via hole...

Embodiment 2

[0066] This embodiment provides a method for manufacturing a transparent electromagnetic induction panel, including:

[0067] The two transparent coil plates produced by the production method of the first embodiment are attached to each other, wherein the coil directions of the two transparent coil plates are perpendicular to each other;

[0068] The terminals of the two transparent coil boards are respectively electrically connected to the corresponding flexible circuit boards 6 .

[0069] Wherein, the terminal of the transparent coil plate is the terminal of the coil circuit drawn from the first transparent induction line 211 / second transparent induction line 226 on both sides of the spiral coil circuit;

[0070] In addition, the forming process of the terminal of the transparent coil board and the forming process of the conductive filler 23 in the via hole 221 can be carried out together by a printing process; finally, the two terminals on the outer edge of the coil loop ar...

Embodiment 3

[0073] This embodiment provides a transparent coil board, including: a transparent conductive substrate, a transparent conductive film attached to the conductive layer of the transparent conductive substrate, and a plurality of parallel first coils formed by the conductive layer of the transparent conductive substrate. A transparent sensing line, and a plurality of parallel second transparent sensing lines formed by the conductive layer of the transparent conductive film, wherein the insulating layer of the transparent conductive film is adjacent to the conductive layer of the transparent conductive substrate;

[0074] The transparent conductive film has a number of via holes, and the first and last positions of the first transparent sensing line and the first and last positions of the second transparent sensing line correspond to the via holes to form a helical coil structure;

[0075] A conductive filler is arranged in the via hole, and the conductive filler electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com