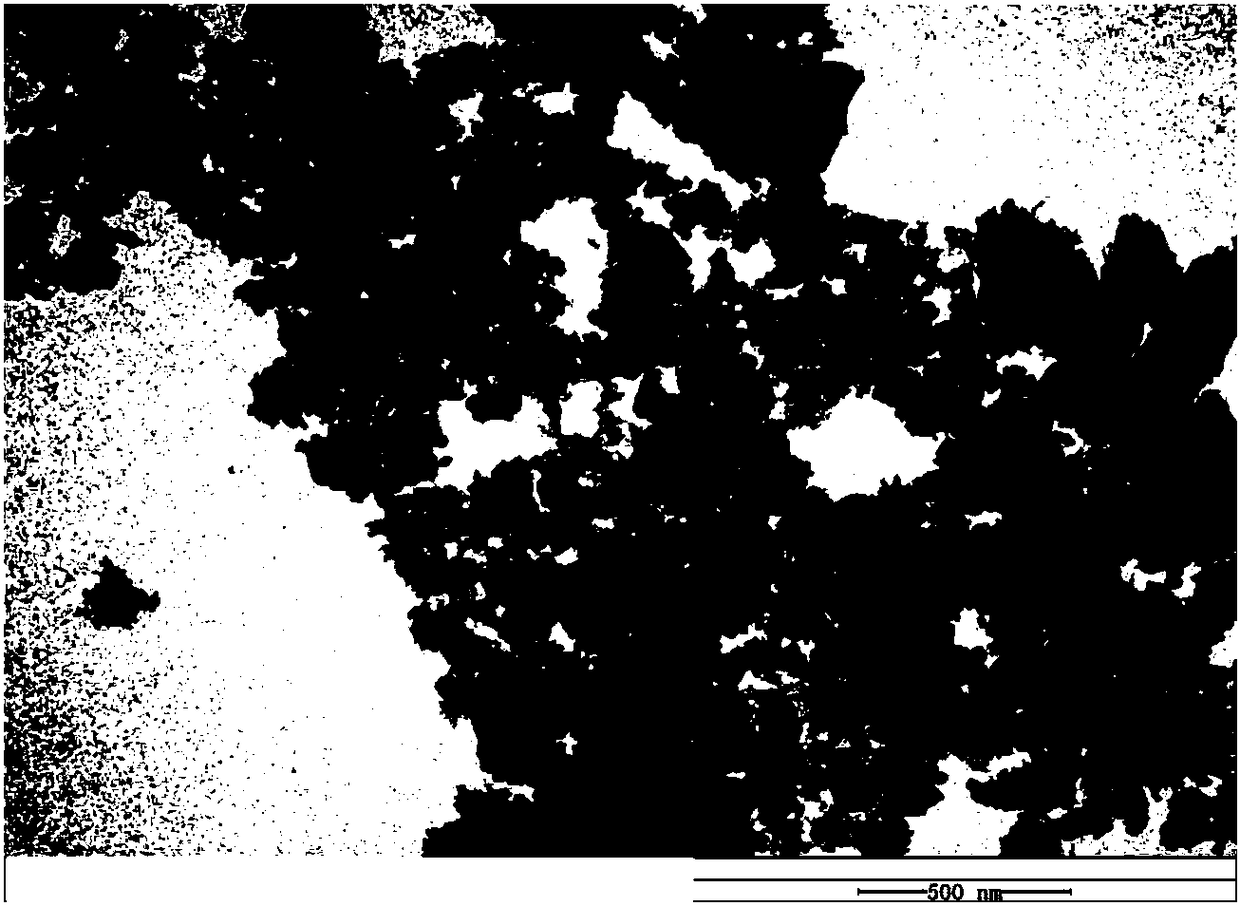

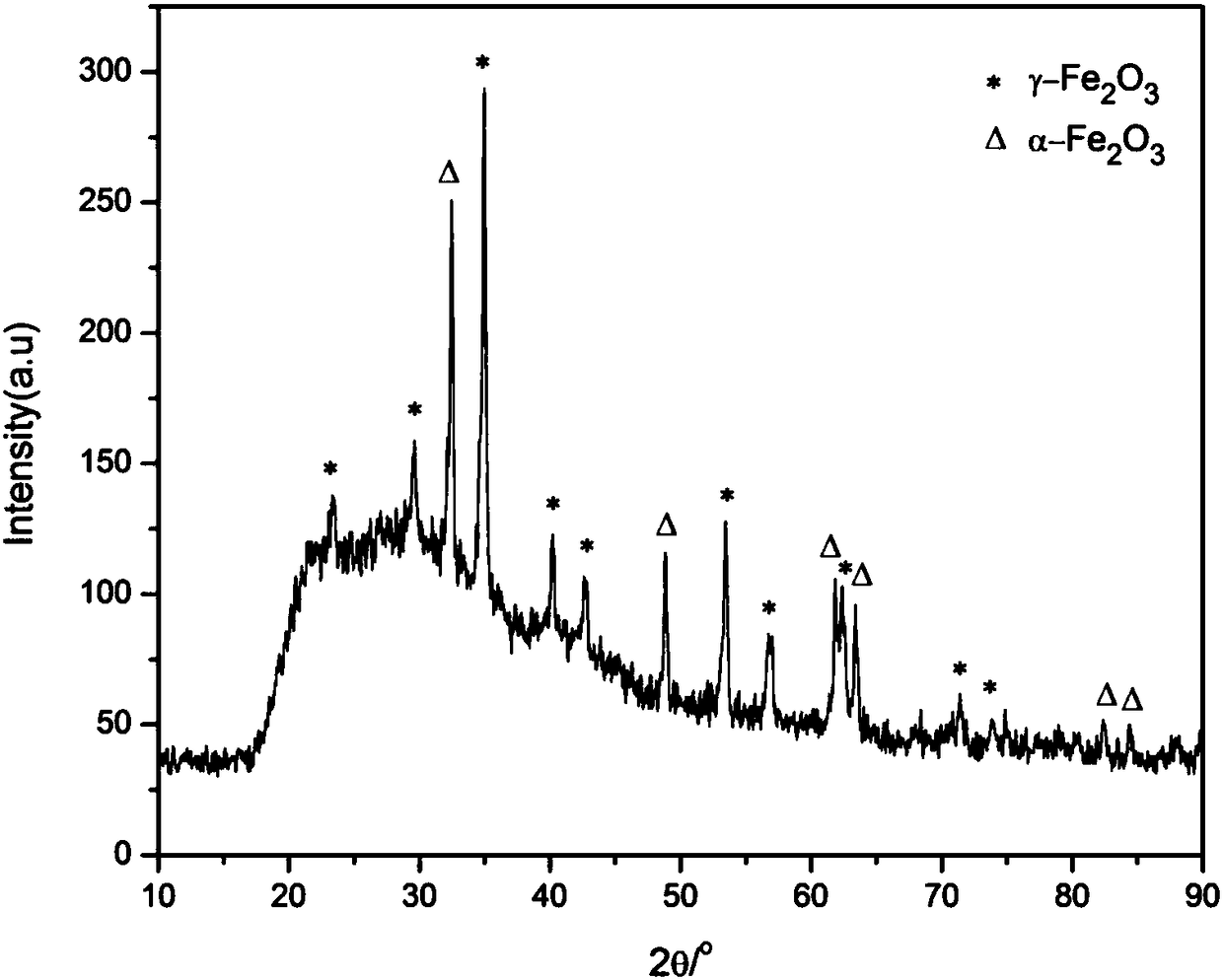

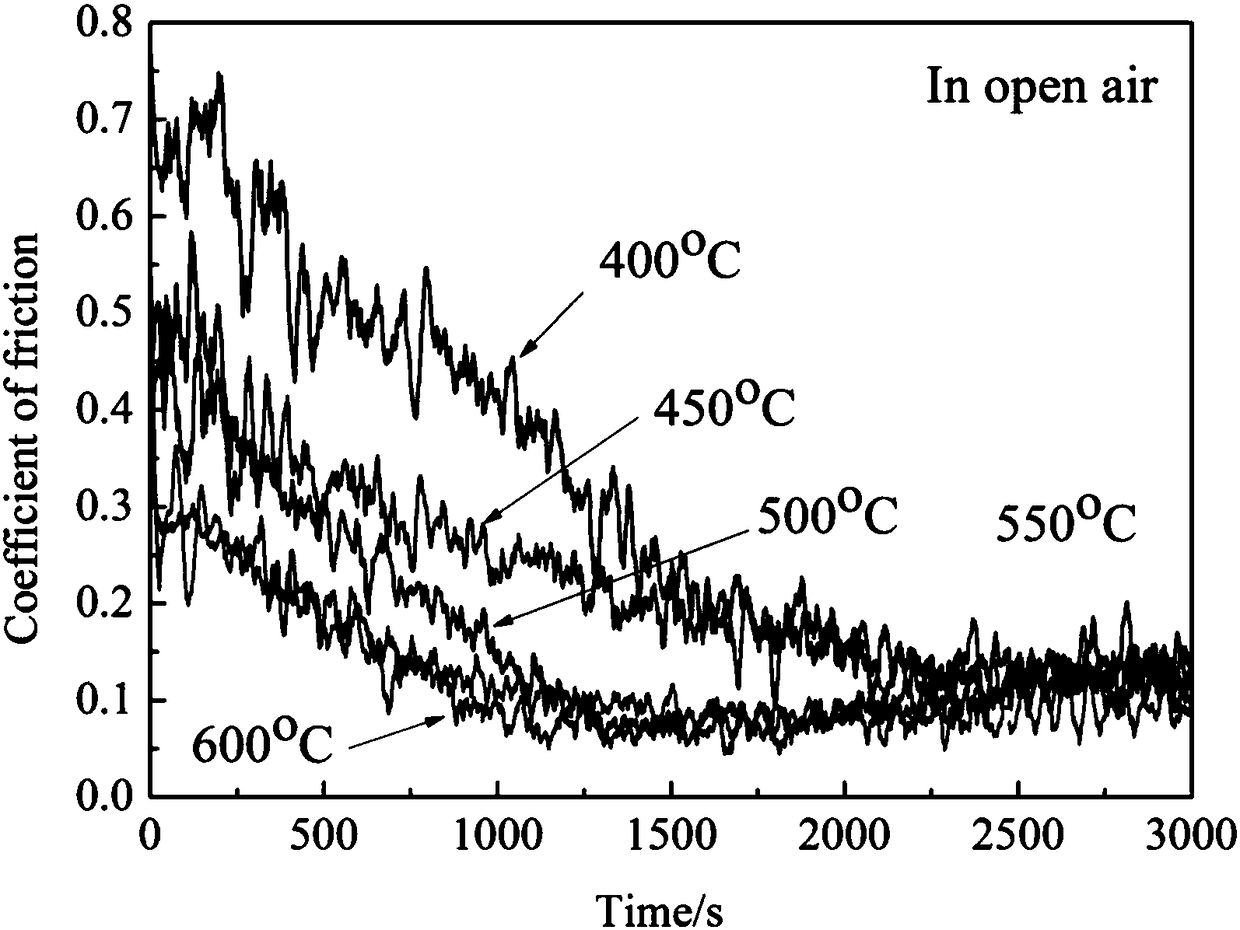

Preparing method of high-temperature low-friction nano gamma-Fe2O3/SiO2 composite coating on steel base body

A composite coating, low-friction technology, applied in the coating, metal material coating process, liquid chemical plating and other directions, can solve problems such as poor coating performance, and achieve the effect of low processing cost and simple process equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The production technology of present embodiment is realized like this:

[0015] The first step is to prepare the sol: take 10.261g (0.0254mol) ferric nitrate nonahydrate lavender crystal and 10ml (0.044mol) ethyl tetrasilicate colorless liquid, pour them into a beaker in turn, then add 45ml ethanol solution, and use a glass rod After stirring to make it evenly mixed, hydrochloric acid was added dropwise to make the solution pH=0.9. Place the beaker on a magnetic stirrer and stir for 2 h to form a transparent sol.

[0016] The second step is to prepare the wet gel: transfer the sol to a Teflon tube (S / V=0.02) with a diameter of 36 mm and a volume of 100 ml, and then place it in a drying oven to dry at 50° C. for 8 days to produce a wet gel.

[0017] The third step of high-speed steel substrate treatment: use a large amount of deionized water to rinse the high-speed steel plate with a diameter of 30 mm to remove large particle pollutants attached to the surface of the hi...

Embodiment 2

[0024] The production technology of present embodiment is realized like this:

[0025] The first step is to prepare the sol: take 10.261g (0.0254mol) ferric nitrate nonahydrate lavender crystal and 10ml (0.044mol) ethyl tetrasilicate colorless liquid, pour them into a beaker in turn, then add 45ml ethanol solution, and use a glass rod After stirring to make it evenly mixed, hydrochloric acid was added dropwise to make the solution pH=0.9. Place the beaker on a magnetic stirrer and stir for 2 h to form a transparent sol.

[0026] The second step is to prepare the wet gel: transfer the sol to a Teflon tube (S / V=0.01) with a diameter of 18 mm and a volume of 100 ml, and then place it in a drying oven to dry at 80° C. for 5 days to produce a wet gel.

[0027] The third step of high-speed steel substrate treatment: use a large amount of deionized water to rinse the high-speed steel plate with a diameter of 30 mm to remove large particle pollutants attached to the surface of the hi...

Embodiment 3

[0032] The production technology of present embodiment is realized like this:

[0033]The first step is to prepare the sol: take 10.261g (0.0254mol) ferric nitrate nonahydrate lavender crystal and 10ml (0.044mol) ethyl tetrasilicate colorless liquid, pour them into a beaker in turn, then add 45ml ethanol solution, and use a glass rod After stirring to make it evenly mixed, hydrochloric acid was added dropwise to make the solution pH=0.9. Place the beaker on a magnetic stirrer and stir for 2 h to form a transparent sol.

[0034] The second step is to prepare the wet gel: transfer the sol to a Teflon tube (S / V=0.02) with a diameter of 36 mm and a volume of 100 ml, and then place it in a drying oven to dry at 80° C. for 5 days to produce a wet gel.

[0035] The third step of high-speed steel substrate treatment: use a large amount of deionized water to rinse the high-speed steel plate with a diameter of 30 mm to remove large particle pollutants attached to the surface of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com