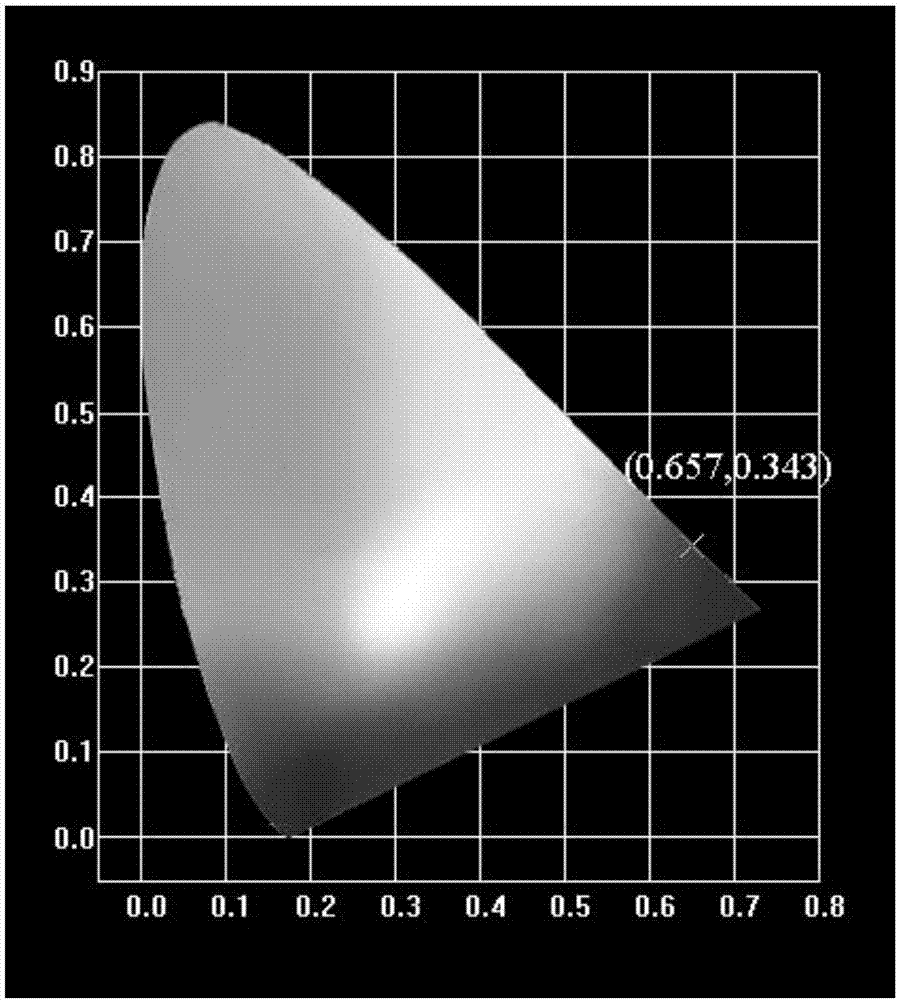

Rare earth europium activated molybdate-based red phosphor powder and preparation method thereof

A red phosphor, molybdate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as unachievable luminous efficiency, and achieve the effects of not easy impurities, stable physical and chemical properties, and low synthesis temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

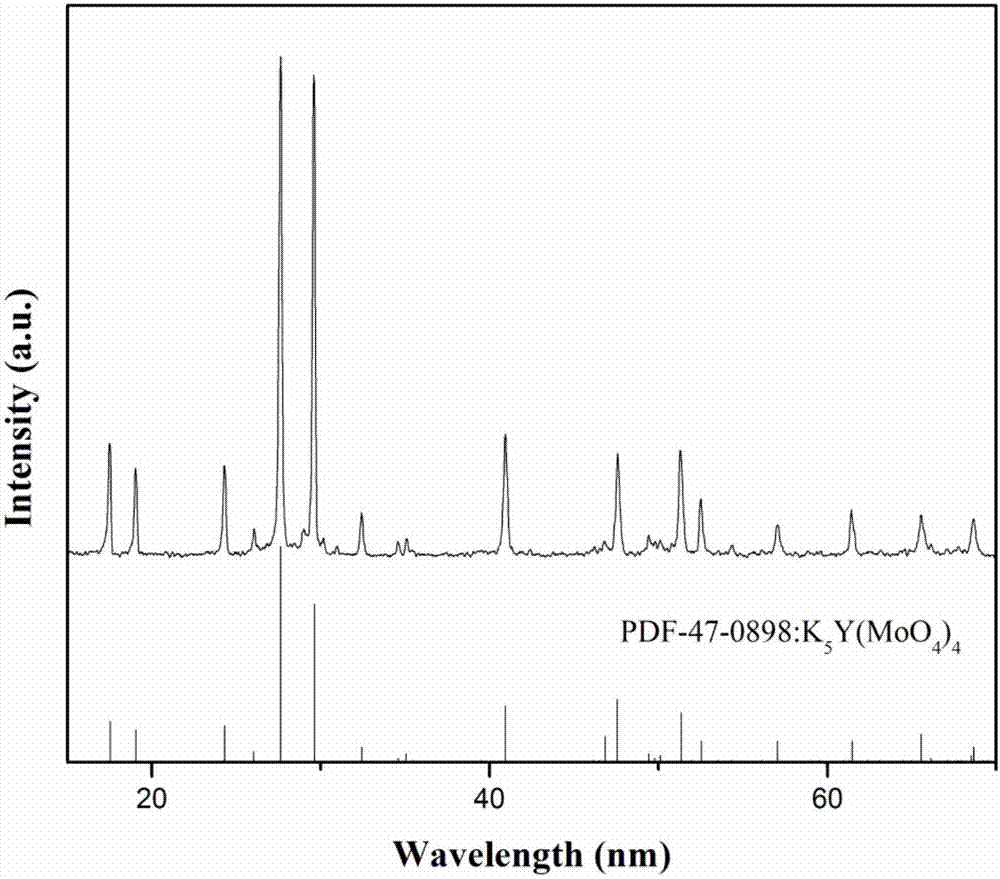

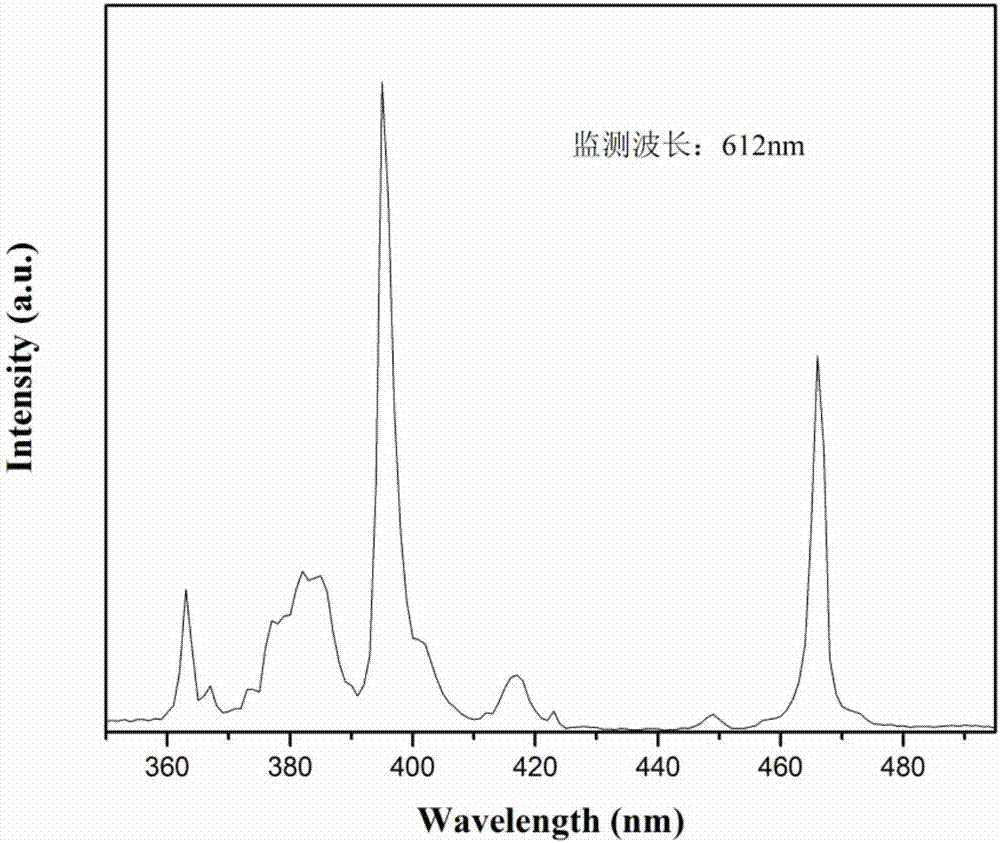

Embodiment 1

[0035] Take x=0.01, according to chemical formula K 5 Y 0.99 (MoO 4 ) 4 :0.01Eu 3+ The stoichiometric ratio, weigh K with electronic balance 2 CO 3 , Y 2 o 3 、MoO 3 and Eu 2 o 3As raw materials, the purity of rare earth oxides is 99.99%, and the rest are analytically pure; mix all the above-mentioned raw materials and grind them for 30 minutes to mix the raw materials evenly to obtain a mixture; put the obtained mixture into corundum Put the corundum crucible in a rapid heating resistance furnace, calcined in the air atmosphere, during this period, the temperature was raised to 600 ° C at a rate of 5 ° C / min, and kept for 3 hours. After the calcination was completed, it was cooled with the furnace until it was cooled to At room temperature, the calcined product was obtained; the calcined product was taken out and ground again for 15 minutes, and the chemical formula was K 5 Y 0.99 (MoO 4 ) 4 :0.01Eu 3+ Rare earth europium activates molybdate-based red phosphor...

Embodiment 2

[0037] Take x=0.02, according to chemical formula K 5 Y 0.98 (MoO 4 ) 4 :0.02Eu 3+ The stoichiometric ratio, weigh K with electronic balance 2 CO 3 , Y 2 o 3 、MoO 3 and Eu 2 o 3 As raw materials, the purity of rare earth oxides is 99.99%, and the rest are analytically pure; mix all the above-mentioned raw materials and grind them for 40 minutes to mix the raw materials evenly to obtain a mixture; put the obtained mixture into corundum Put the corundum crucible in a rapid heating resistance furnace, and calcined it in an air atmosphere. During this period, the temperature was raised to 750°C at a rate of 7°C / min, and kept for 5h. After the calcination was completed, it was cooled with the furnace until it was cooled to At room temperature, the calcined product was obtained; the calcined product was taken out and ground again for 20 minutes, and the chemical formula was K 5 Y 0.98 (MoO 4 ) 4 :0.02Eu 3+ Rare earth europium activates molybdate-based red phosphor.

...

Embodiment 3

[0040] Take x=0.04, according to chemical formula K 5 Y 0.96 (MoO 4 ) 4 :0.04Eu 3+ The stoichiometric ratio, weigh K with electronic balance 2 CO 3 , Y 2 o 3 、MoO 3 and Eu 2 o 3 As raw materials, the purity of rare earth oxides is 99.99%, and the rest are analytically pure; mix all the above-mentioned raw materials and grind them for 60 minutes to mix the raw materials evenly to obtain a mixture; put the obtained mixture into corundum Put the corundum crucible in a rapid heating resistance furnace, calcined in the air atmosphere, during this period, the temperature was raised to 850°C at a rate of 8°C / min, and kept for 6h. After the calcination was completed, it was cooled with the furnace until it was cooled to At room temperature, the calcined product was obtained; the calcined product was taken out and grinded again for 30 minutes to obtain the chemical formula K 5 Y 0.96 (MoO 4 ) 4 :0.04Eu 3+ Rare earth europium activates molybdate-based red phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com