A flotation column scraping device

A flotation column and flotation technology, used in flotation, solid separation and other directions, can solve the problem of slow foam overflow in the central area, and achieve the effect of saving electric energy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

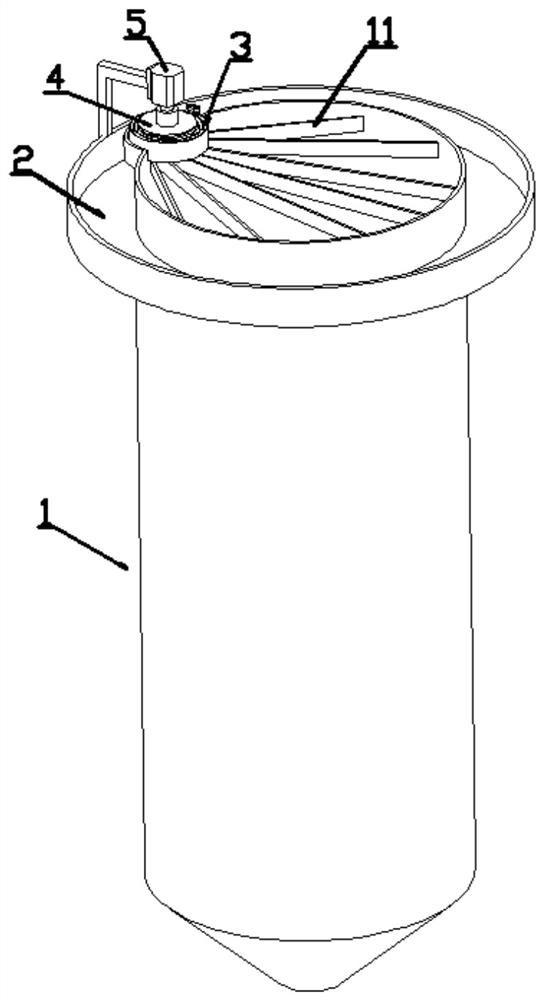

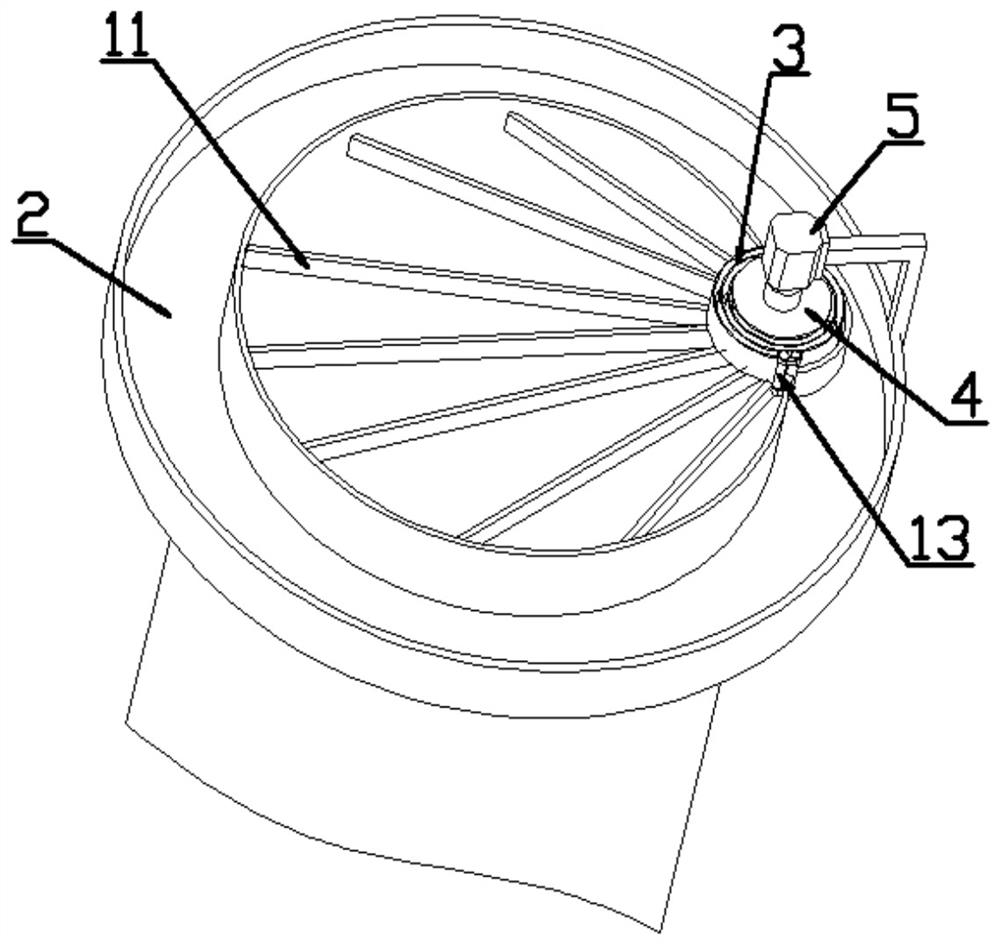

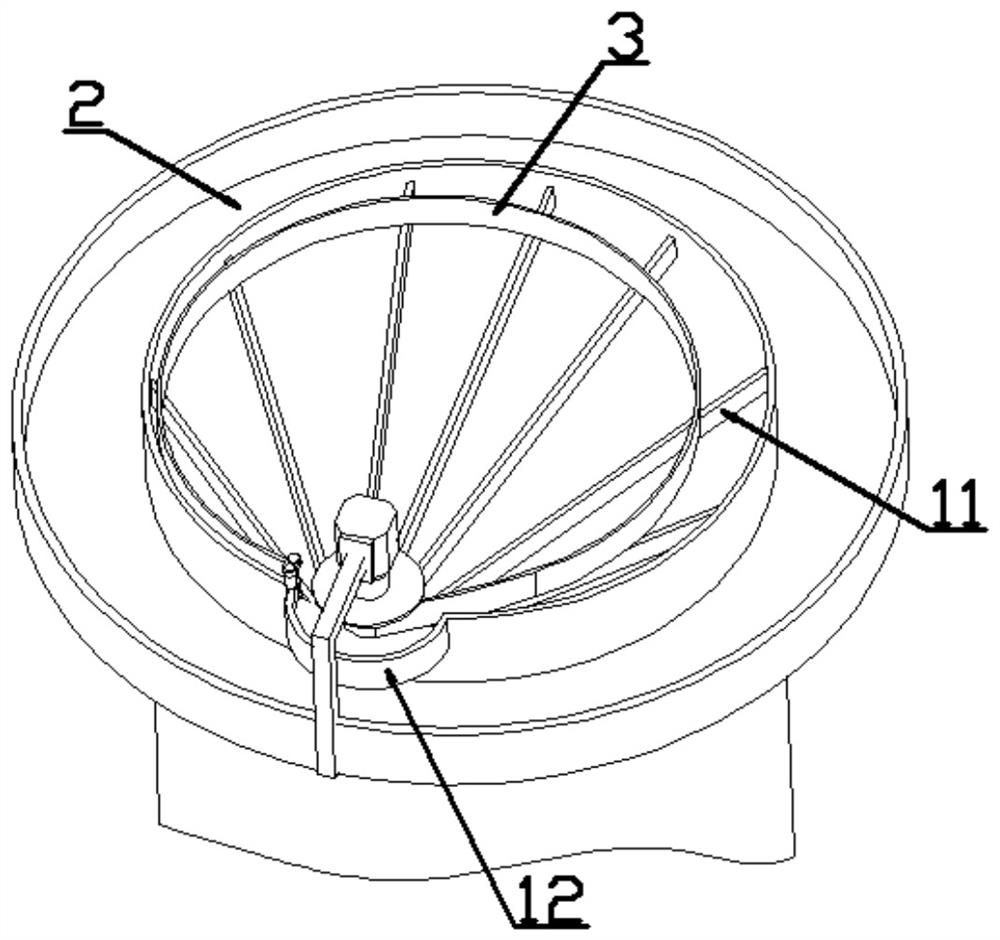

[0025] A kind of flotation column scraping device, such as figure 1 As shown, it includes a flotation cylinder 1 and a foam collection tank 2, and also includes a clockwork spring 3. The clockwork spring 3 is made of 65Mn material, has elastic potential energy, and is usually used in an energy storage device or a torsion device. The barrel wall of the flotation cylinder 1 is provided with a barrel 12 for accommodating the clockwork spring 3 . In order to ensure a uniform overflow surface, the upper end surface of the barrel 12 is flush with the upper end surface of the flotation barrel 1 . A support member 11 for supporting the lower surface of the clockwork spring 3 is provided in the flotation cell 1, the support member 11 is a strip plate, and the strip plate is fan-shaped with the winding shaft 4 as the center.

[0026] Such as figure 2 As shown, the inner wall of the flotation cell 1 is provided with a fixed shaft 13, the outer coiled end of the clockwork spring 3 is ...

Embodiment 2

[0029] A flotation column scraping device as described in Embodiment 1, the difference from Embodiment 1 is that the motor 5 is a servo motor. The control system can control the number of rotations, positive and negative rotation and intermittent time of the servo motor in many aspects. Obviously, the same control effect as that of Example 1 can be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com