Washing machine, dewatering bucket assembly and waterfall spraying cover plate

A cover plate and component technology, applied in the field of washing machines, can solve the problems of small spray coverage, high risk of clothing entanglement, weak water spray intensity, etc., so as to reduce the probability of spray dead corners, reduce the risk of clothing entanglement, and improve spray Effects of distance and spray intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

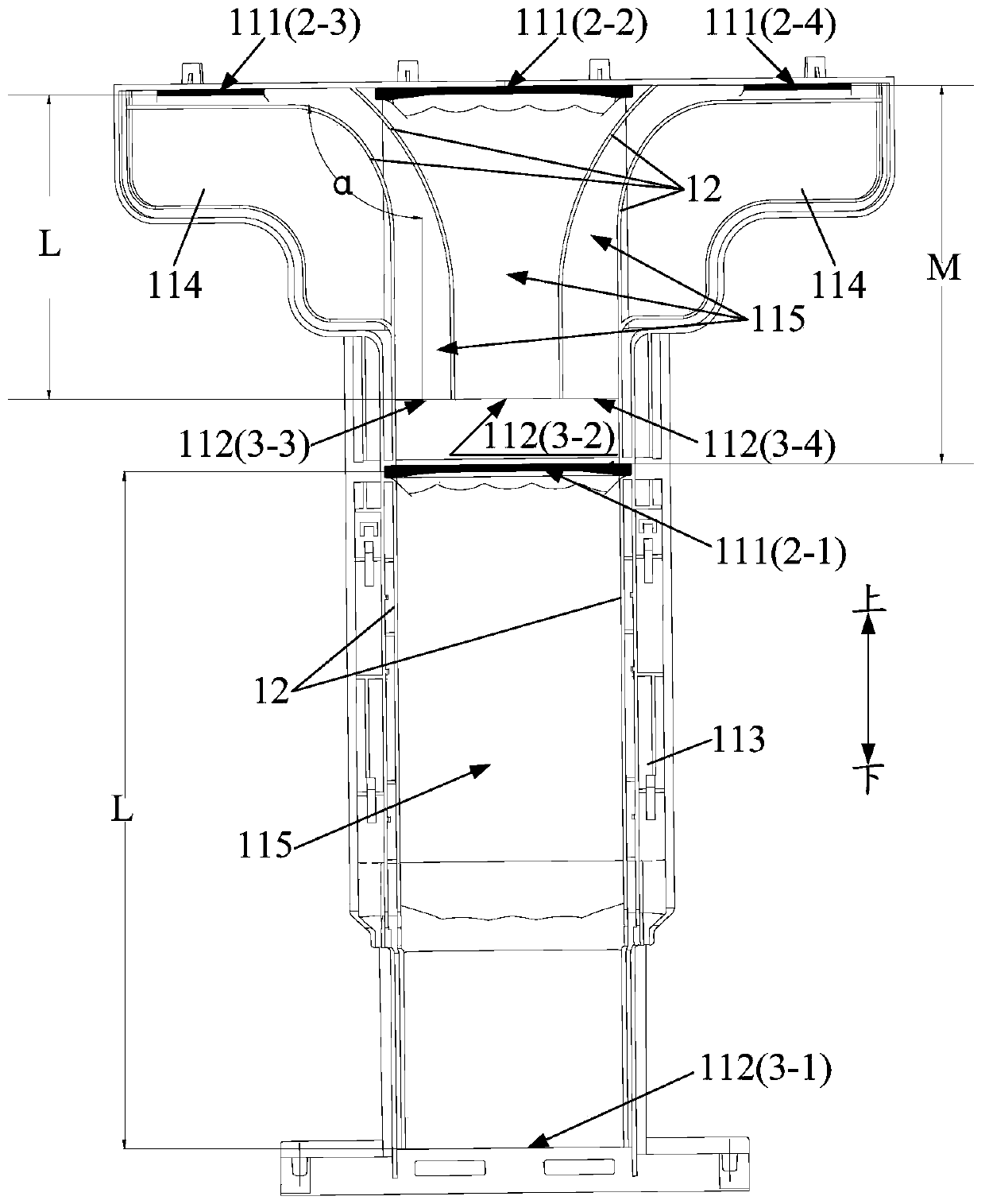

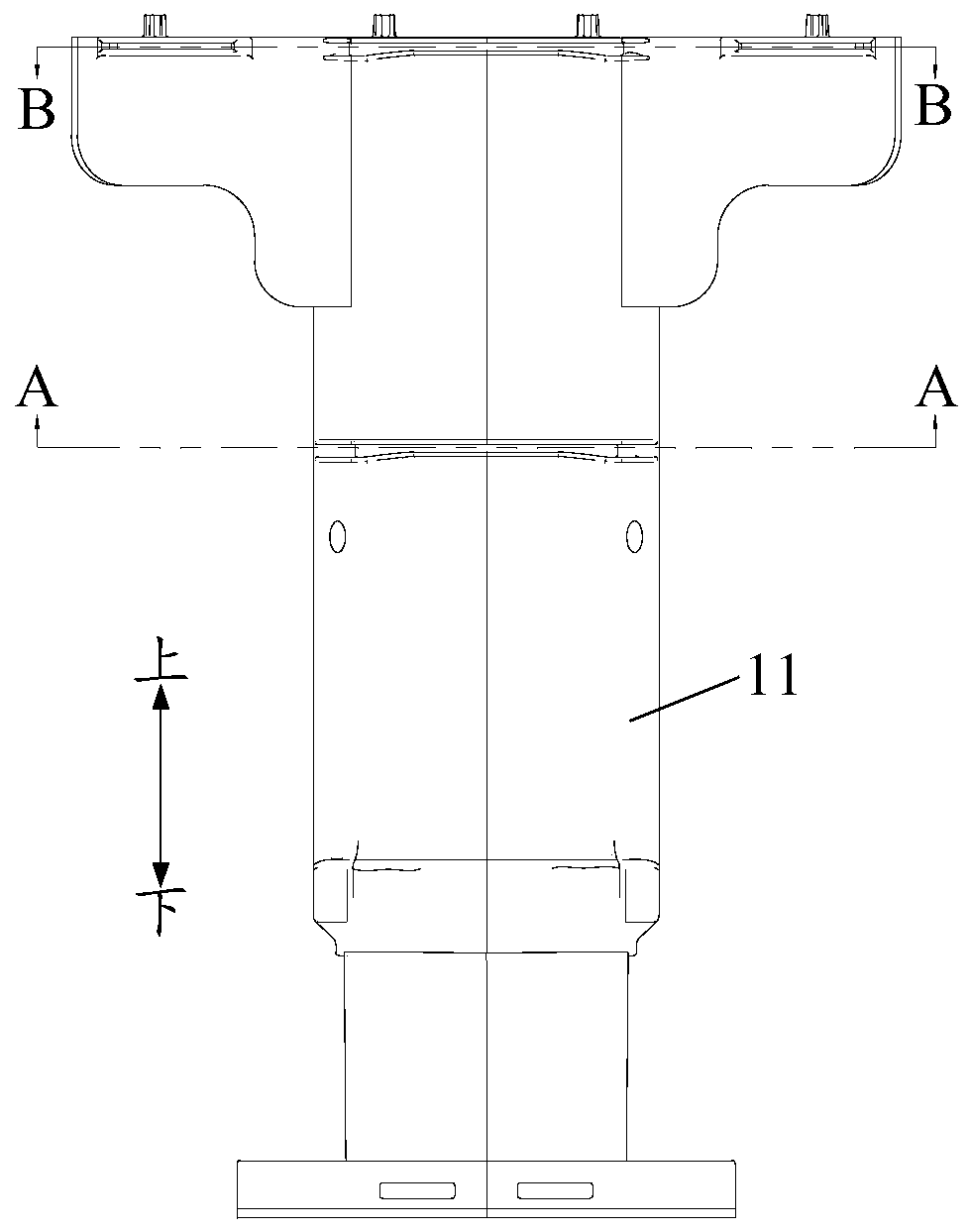

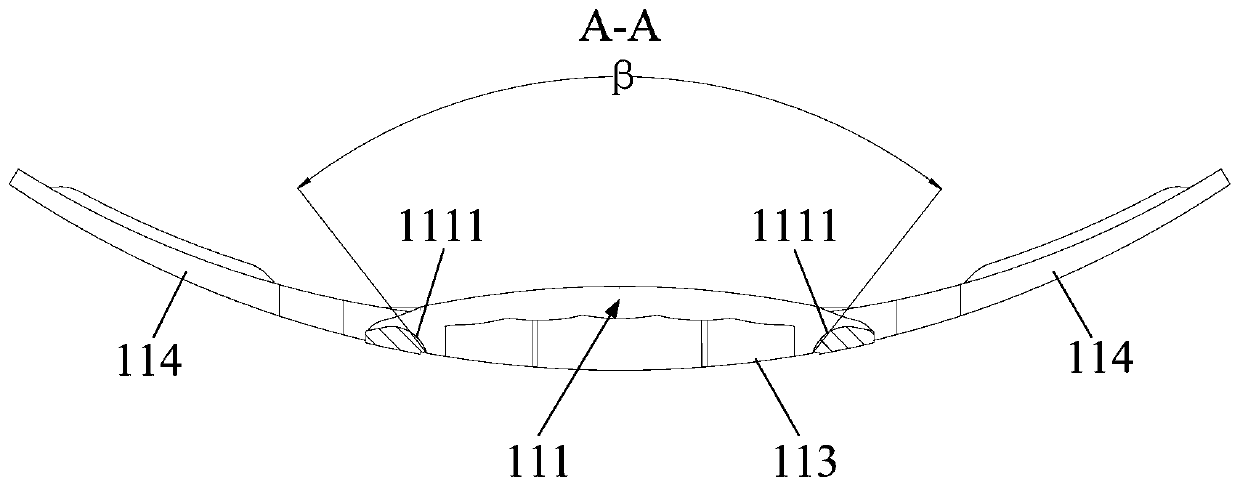

[0073] The diversion channel includes a plurality of independent waterfall flow channels 115, the number of waterfall holes 111 is equal to the number of waterfall flow channels 115 and corresponds to each other and the number of water inlet holes 112 is equal to the number of waterfall flow channels 115 And one-to-one correspondence, the two ends of a plurality of waterfall flow channels 115 are respectively connected with a plurality of waterfall holes 111 and a plurality of water inlet holes 112, such as figure 1 shown.

[0074] The diversion channel is divided into a plurality of mutually independent waterfall channels 115, and the plurality of waterfall channels 115 correspond to and communicate with the plurality of waterfall holes 111 and the plurality of water inlet holes 112 respectively, namely: one waterfall The flow path 115 corresponds to a water inlet hole 112 and a waterfall hole 111. During the washing process, the water flow in the washing chamber enters the w...

Embodiment 2

[0091] The difference from Embodiment 1 is: on the basis of Embodiment 1, further, the positions of the plurality of waterfall holes 111 have different heights, such as figure 1 shown.

[0092] In the prior art, there is only one waterfall hole 111 and its position is fixed, so when the water level is low, the water pressure may not be enough to raise the water flow to the waterfall hole 111, and the waterfall hole 111 cannot flow to the waterfall hole 111. Clothes are sprayed with water, causing the clothes to be easily entangled. Based on this, the present application makes the positions of multiple spray holes 111 have different heights by rationally arranging the positions of the multiple spray holes 111, so that the lower spray holes 111 can play an important role when the water level is low. Waterfall effect, and the waterfall hole 111 at a higher position can play a major role in the waterfall when the water level is high, thereby meeting the needs of waterfalls at dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com