Deep sea durability testing device and method of ocean instrument equipment

A technology for marine instruments and testing devices, applied in the field of deep-sea durability testing devices, can solve the problems that autonomous marine instruments and equipment lack long-term marine testing conditions, methods, devices and environments, limited testing time, and high testing risks, and achieve reliable testing. method, high utilization, and the effect of reducing trial risk and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

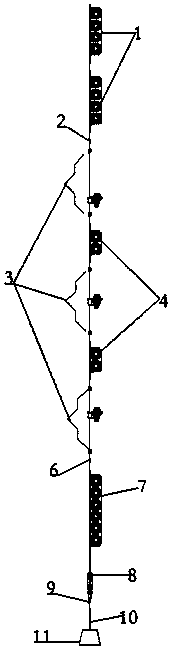

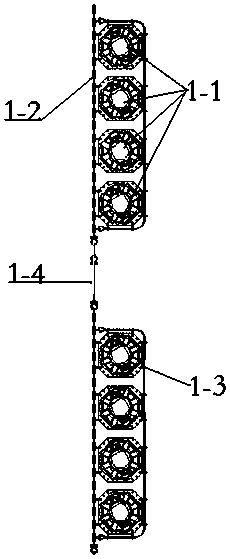

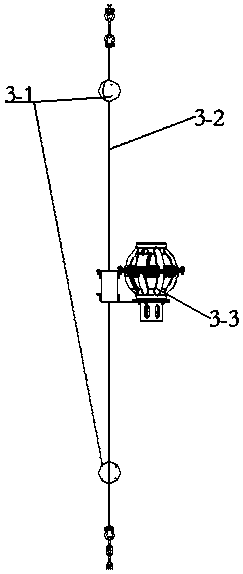

Embodiment 1

[0042] Such as Figures 1 to 4 As shown, the present invention proposes a deep-sea durability test device for marine instruments and equipment, which includes a first glass float section 1, a first water depth adjustment section 2, a second water depth adjustment section 6, and a third glass float ball from top to bottom. Ball section 7, acoustic release device 8, third water depth adjustment section 9, composite connection section 10 and gravity anchor 11, wherein a plurality of second glass floats are arranged between the first water depth adjustment section 2 and the second water depth adjustment section 6 Section 4 and a plurality of tested test sections 3, the number of the second glass float section and the tested test section can be flexibly installed according to specific test tasks, the second glass float section 4 and the tested test section 3 are arranged at intervals, and the The purpose of being arranged at intervals between the tested test section 3 and the secon...

Embodiment 2

[0062] Such as Figure 1-4 As shown, this embodiment provides a deep-sea durability testing device for marine instruments and equipment. On the basis of the above-mentioned embodiments, this embodiment further makes an improved technical solution: the passive connection assembly 3-4 can also be provided with For having a square structure, the inside of the square structure is equipped with guide wheels. Under the traction of the passive connection components, the prototype under test moves on the cable of the test section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com