A large-scale isolator with hidden resistance

A hidden isolator technology, applied in resistors, resistor components, resistor installation/support, etc., can solve the problems of isolators hindering resistance heat dissipation, isolator installation occupying large space, and unable to achieve rapid resistance cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

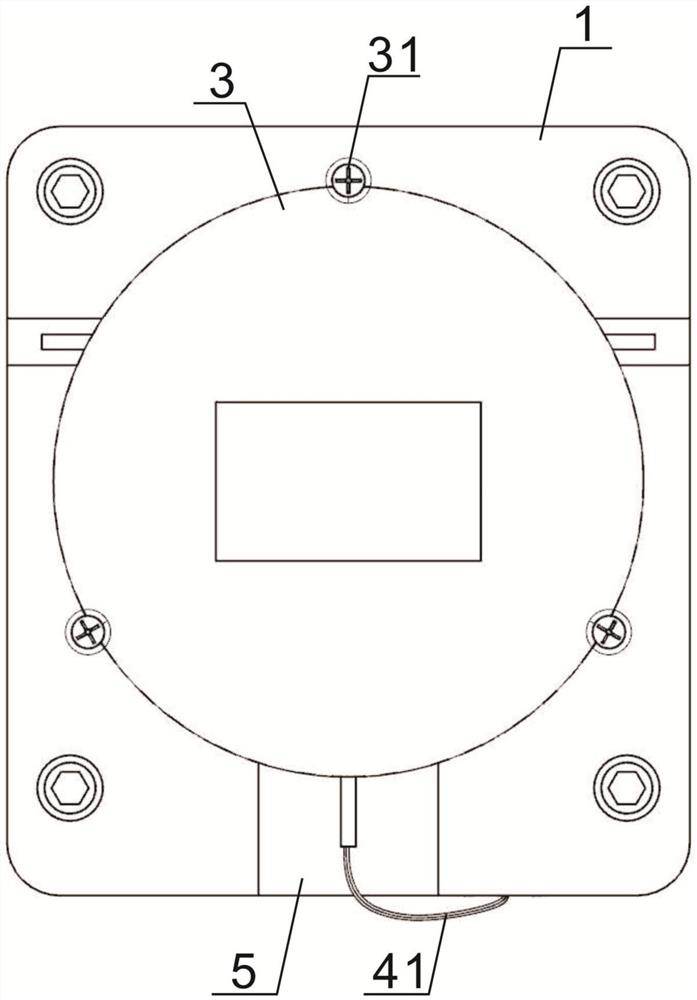

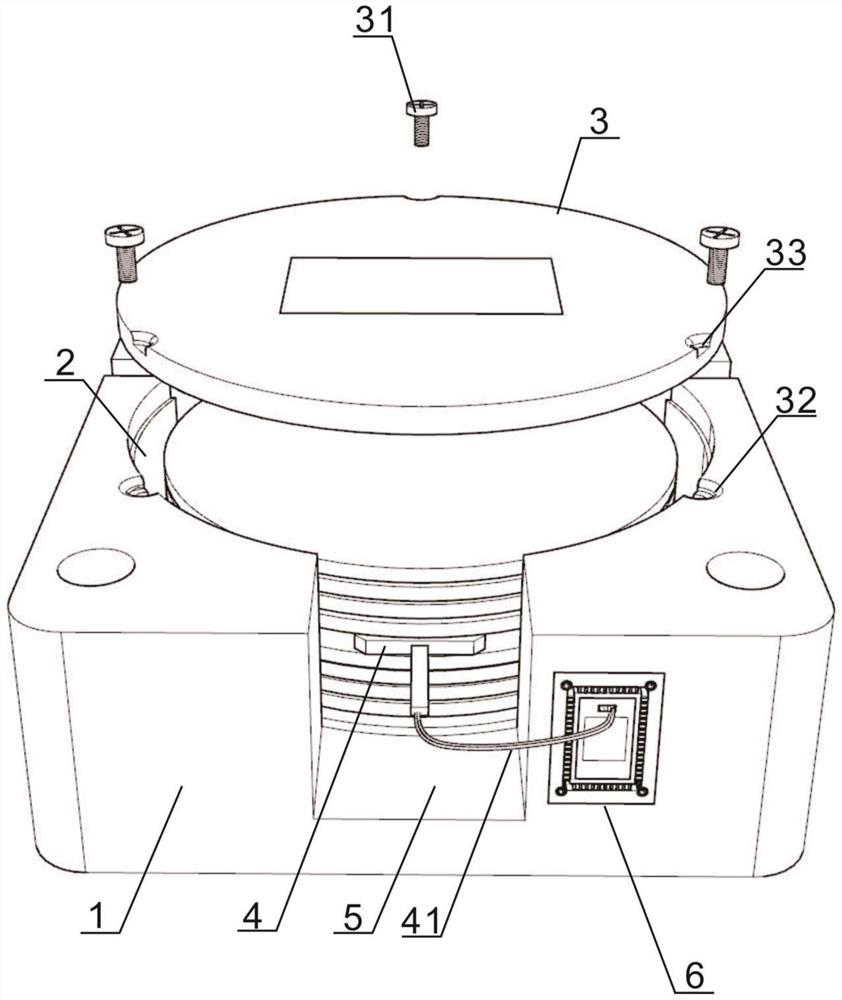

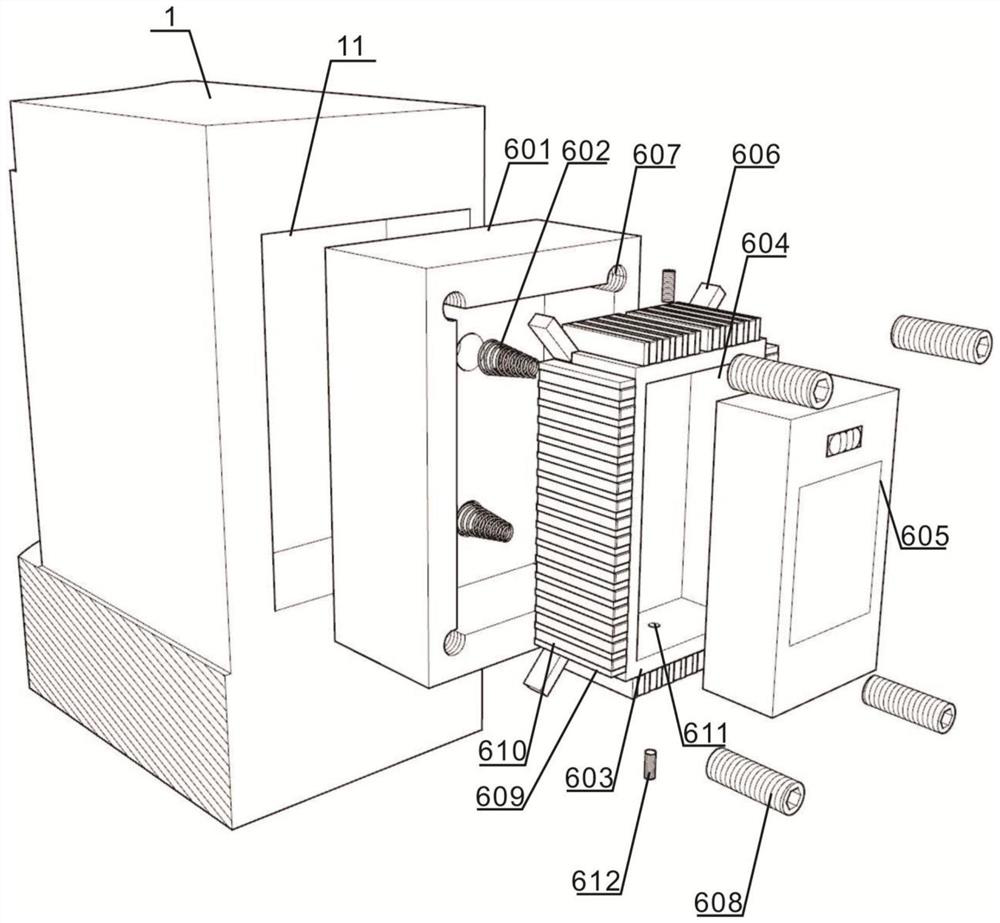

[0018] Figure 1-3 An embodiment of the present invention is a large-scale isolator with hidden resistance. The isolator includes a protective casing 1, the front of the casing 1 is provided with an inner cavity 2 with an open top, and internal components are arranged in the inner cavity 2, and a top for covering the inner cavity 2 is arranged on the top of the inner cavity 2. Cover 3. There is a central conductor 4 with three pins in the internal assembly, and one of the front pins is a resistor connection pin for soldering connection resistors. And three notches 5 are respectively set corresponding to three pins on the side of installation case 1, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com