Improved process for manufacturing sheets made of aluminium-copper-lithium alloy for aircraft fuselage manufacture

A manufacturing method, technology for aluminum alloys, applied in the manufacture of fuselage panels, in the field of constraints in the aviation and aerospace industry, capable of solving problems such as degraded performance and not being able to withstand optimized manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Alloy A having the composition shown in Table 1 is an alloy of the present invention.

[0058] Table 1 - Chemical composition (weight %)

[0059] Casting mark Si Fe Cu mn Mg Zr Li Ag Ti A 0.01 0.03 2.3 0.3 0.3 <0.01

1.4 <0.01

0.03

[0060] SOES (Spark Optical Emission Spectroscopy) analysis was performed on the solid.

[0061] Average values were taken for three samples.

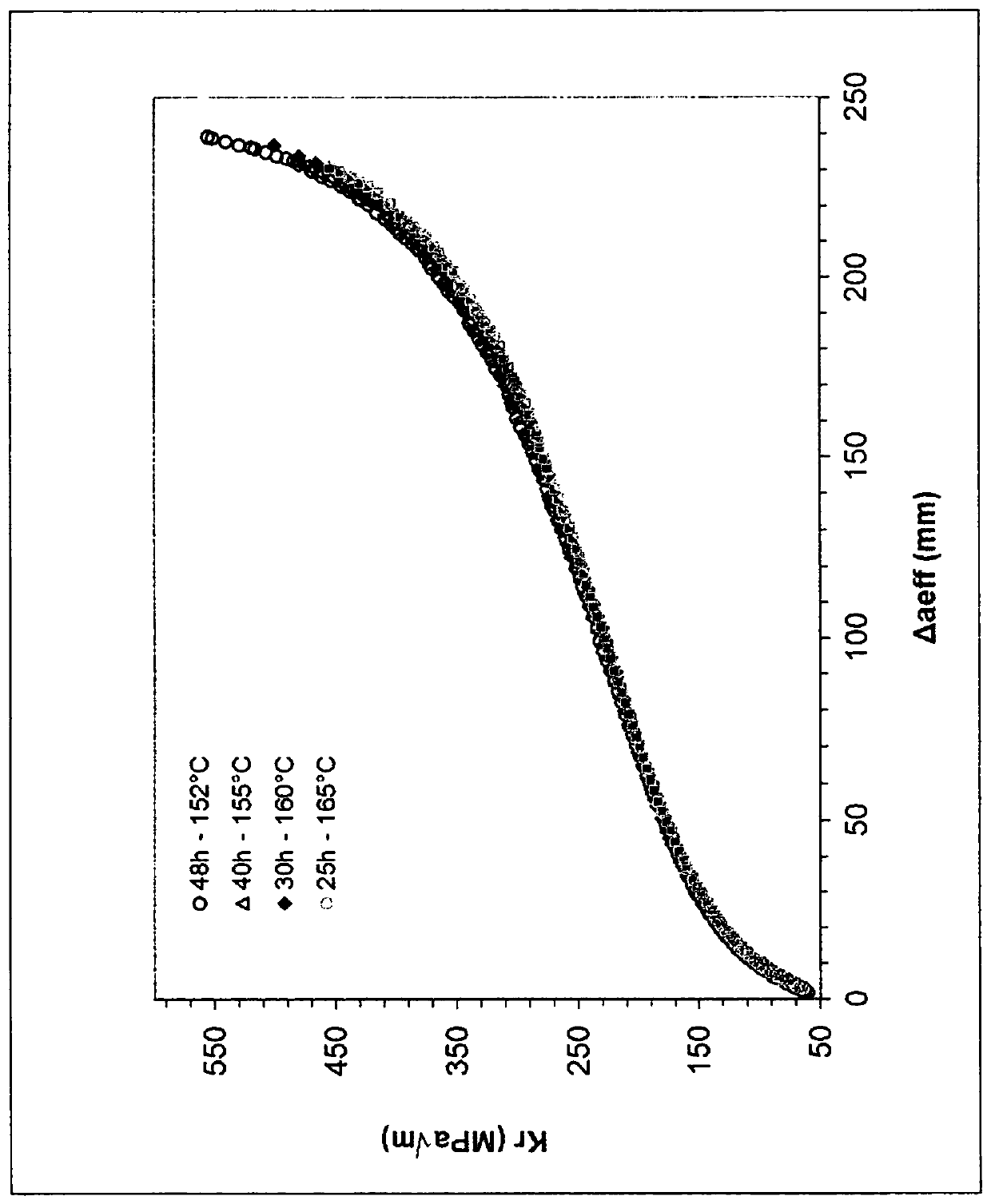

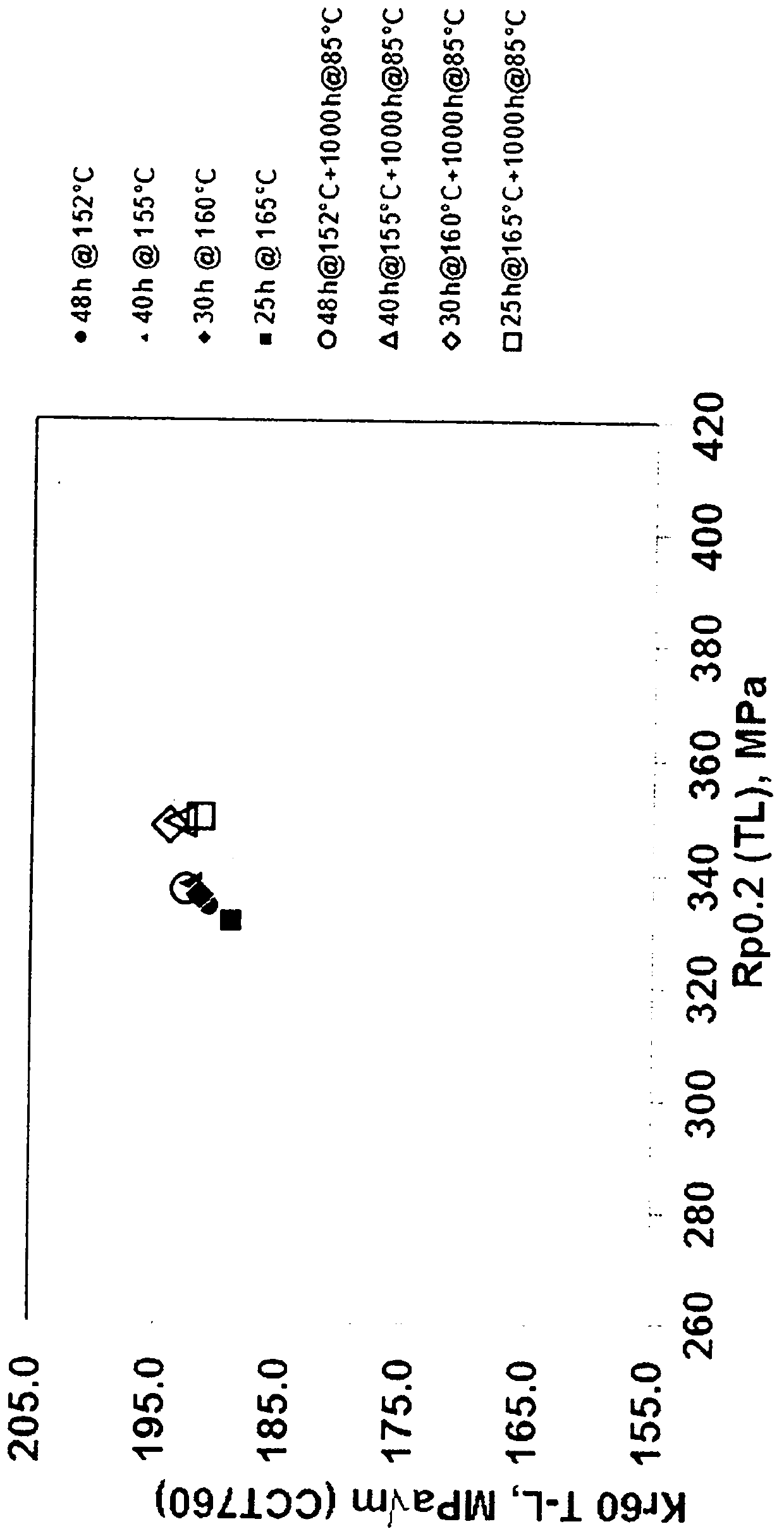

[0062] The method used to manufacture plates made of Alloy A was as follows: An ingot made of Alloy A with a thickness of about 400 mm was cast, homogenized at 508° C. for about 12 hours, and then peeled. The ingot was hot rolled to obtain a plate with a thickness of 4 mm. It is solution heat treated at about 500°C and then quenched with cold water. The panels were then stretched with a permanent elongation of 3 to 4%. The following aging treatments were performed on each plate sample: 48h-152°C, 40h-155°C, 30h-160°C and 25h-165°C.

[0063] For e...

Embodiment 2

[0072] Alloy B with the composition shown in Table 4 is a reference alloy known inter alia from document EP 1 966 402 B2.

[0073] Table 4 - Chemical composition (weight %)

[0074] Casting mark Si Fe Cu mn Mg Zr Li Ag Ti B 0.03 0.03 2.4 0.3 0.3 <0.01

1.4 0.34 0.02

[0075] SOES (Spark Optical Emission Spectroscopy) analysis was performed on the solid.

[0076] Take the average of the three samples.

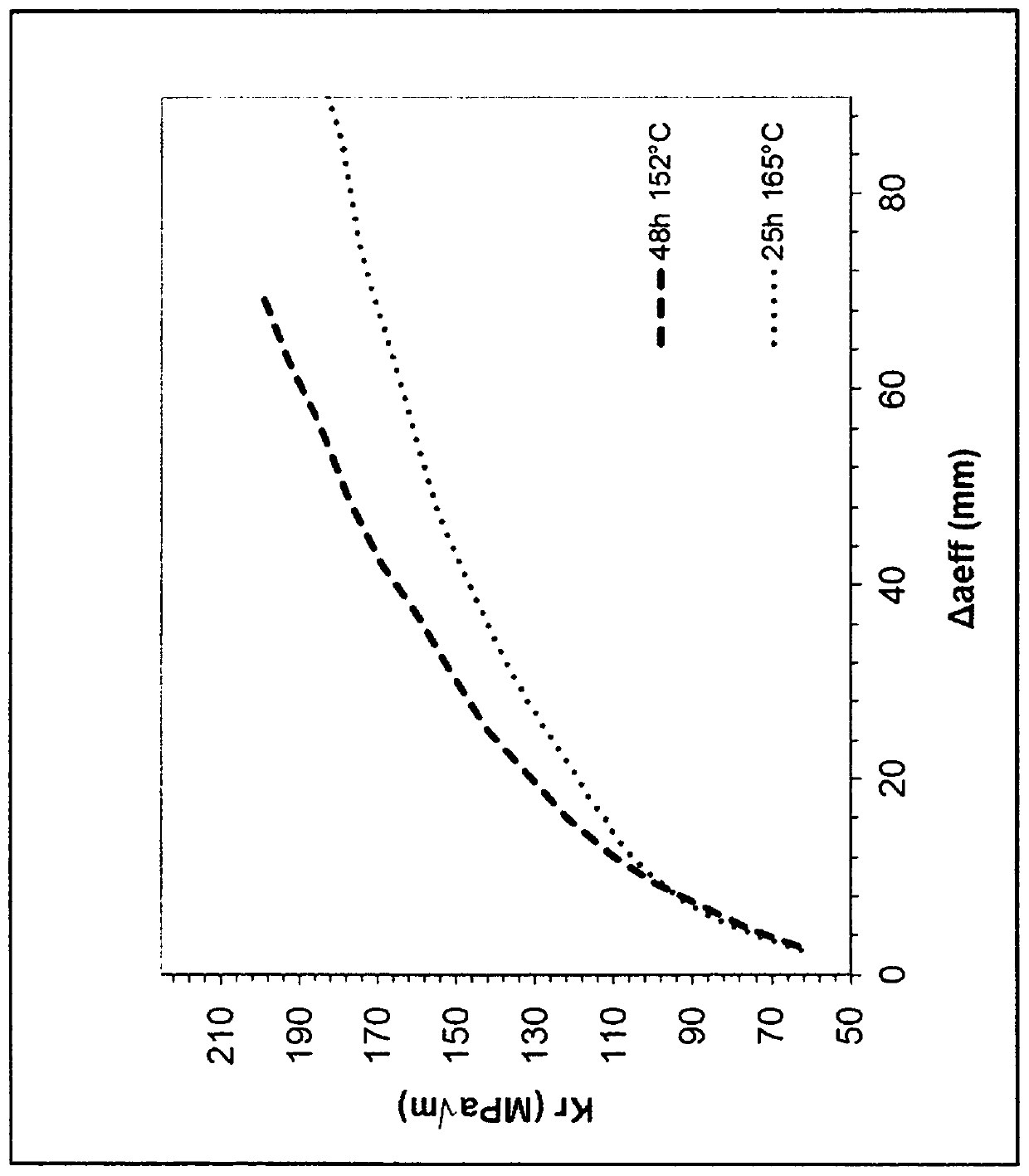

[0077] The method used to manufacture plates made of alloy B was as follows: an ingot made of alloy B with a thickness of about 400 mm was cast, homogenized at 500° C. for about 12 hours, and then peeled. The ingot was hot rolled to obtain a plate with a thickness of 5 mm. It is solution heat treated at about 500°C and then quenched with cold water. The panels are then stretched with a permanent elongation of 1 to 5%. The following aging treatments were performed on each panel sample: 48h-152°C and 25h-165°C.

[0078] According ...

Embodiment 3

[0086] The effect of high temperature aging treatments has also been studied in the literature. This example reproduces the data presented in the articles cited below that disclose the known effects of high temperature aging treatments, such as the high temperature aging treatment of the present invention, on the toughness of aluminum alloys containing, inter alia, copper and lithium:

[0087] _Effects of aging treatment on strength and fracture toughness of 2A97 aluminum-lithium alloy, S.Zhong et al., The Chinese Journal of Nonferrous Metals, Volume 21, n3, 2011

[0088] _The effect of aging temperature on the fracture toughness of an8090 Al-Li alloy, K.J.Duncan and J.W.Martin, Journal of Materials Science Letters, Vol. 10, No. 18, pp. 1098-1100, 1991.

[0089] The article by Zhong et al. deals with Al-Cu-Li alloy 2A97. It reveals a reduction in toughness caused by an increase in temperature in the second aging treatment step of a product made of 2A97 alloy in a two-step agi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com