Improved stone-like coating dispersion machine

A real stone paint and dispersing machine technology, which is applied to mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems of uneven dispersion, affecting the quality of finished products, and inconvenient operation, so as to achieve convenient operation and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

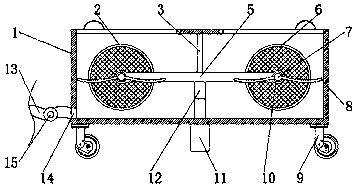

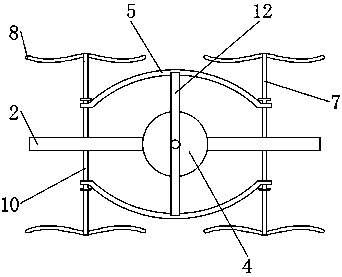

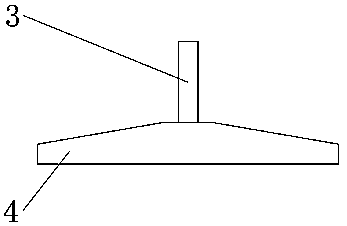

[0027] Such as Figure 1-3 As shown, the embodiment of the present invention provides an improved real stone paint disperser, including a dispersion box body 1, a servo motor 11, a roller 9, a discharge port 14, a discharge catheter 13 and a control valve 15, and the dispersion box body 1 There is a fixed gear 4 inside, the top of the fixed gear 4 is fixedly connected with a fixed rod 3, and the end of the fixed rod 3 away from the fixed gear 4 is fixedly connected with the inner top of the dispersion box body 1, and both sides of the fixed gear 4 are provided with transmission gears. Gear 2, two transmission gears 2 are symmetrically distributed with respect to the fixed gear 4, both transmission gears 2 are meshed with the fixed gear 4, and the center positions of the two transmission gears 2 are connected with a connecting shaft 10, and the connecting shaft 10 is connected to the transmission The gear 2 is fixedly connected, the driving end of the servo motor 11 extends thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com