Temporary storage device for ring-pull can cover body, and packaging equipment with temporary storage device

A can and lid technology, applied in the field of packaging equipment, can solve problems such as the complexity of the whole machine, the difficulty in matching the packaging speed of the packaging equipment and the speed of supplying the lids of the lid production line, the inability of the packaging equipment and the lid production line to be connected, and the like, and the production cost can be reached. The effect of low height, simple structure and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

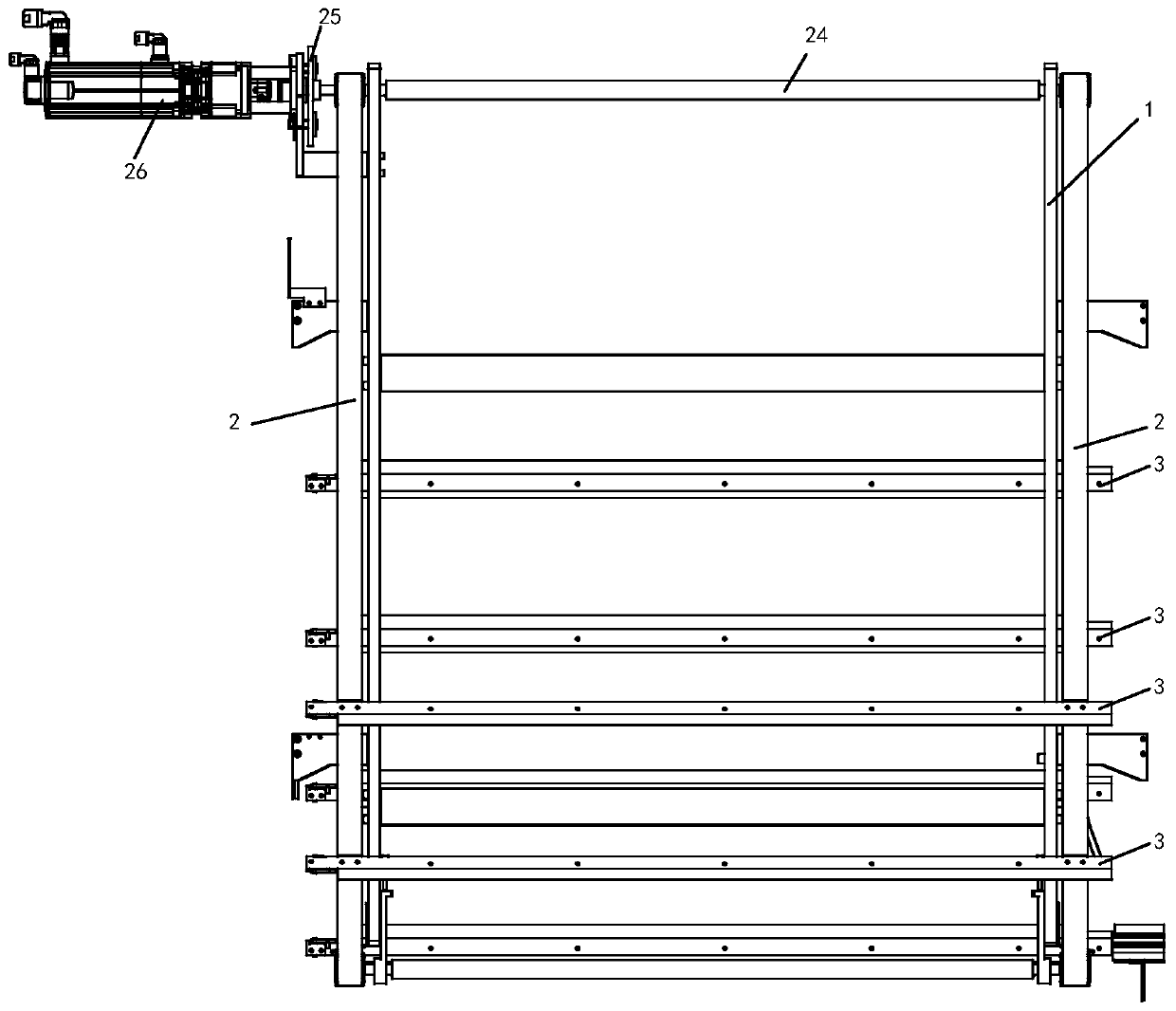

[0043] Embodiment one: see Figure 3-7 Shown:

[0044] A temporary storage device for pop can lids, comprising a frame 1, the frame 1 refers to a base frame structure, such as Figure 3-5 As shown in , the example frame 1 is composed of a front frame and a rear frame. The front frame and the rear frame have the same structure, and both are composed of two columns and a transverse connecting rod connected between the two columns. In practice, the frame 1 can also be of other structures, and it is just a fixed and fixed body of the temporary storage device for the lid body of the pop can.

[0045] see Figure 3-7 As shown, the first vertical surface on the front side and the second vertical surface on the rear side are defined on the frame 1, and the first vertical surface and the second vertical surface are parallel. For example, in the figure, the first The vertical plane and the second vertical plane are perpendicular to the horizontal plane.

[0046] see Figure 3-7 As ...

Embodiment 2

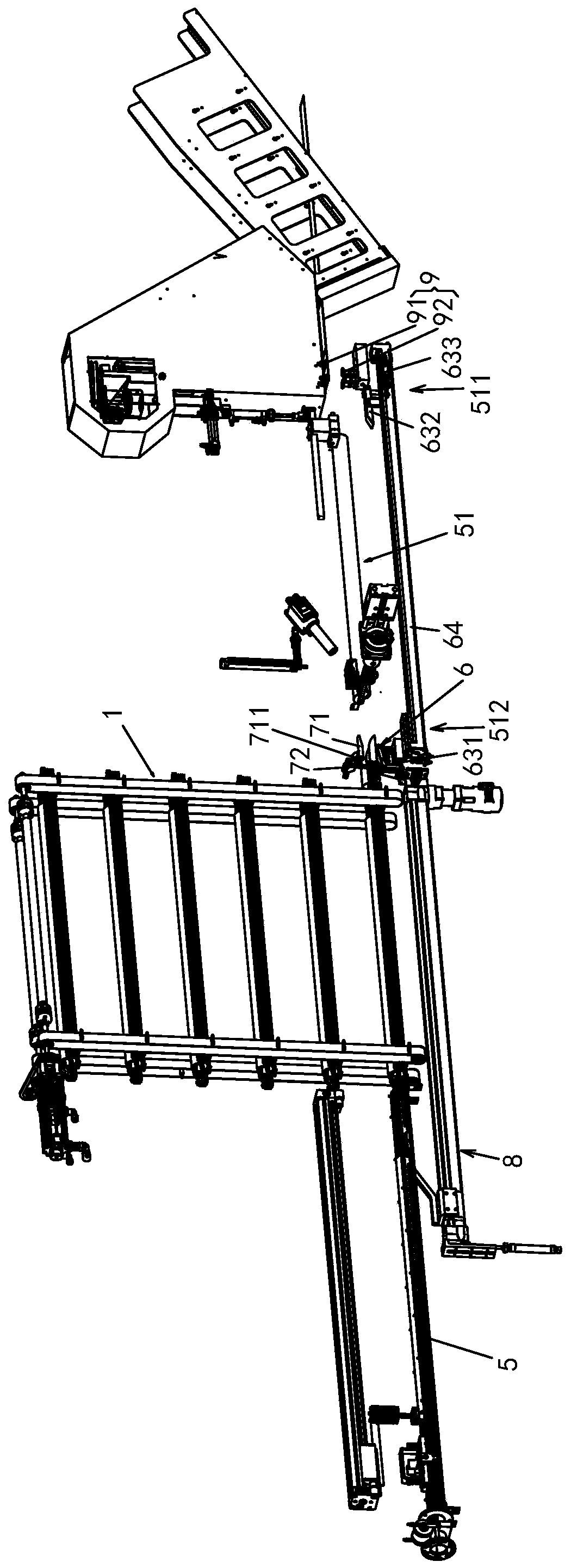

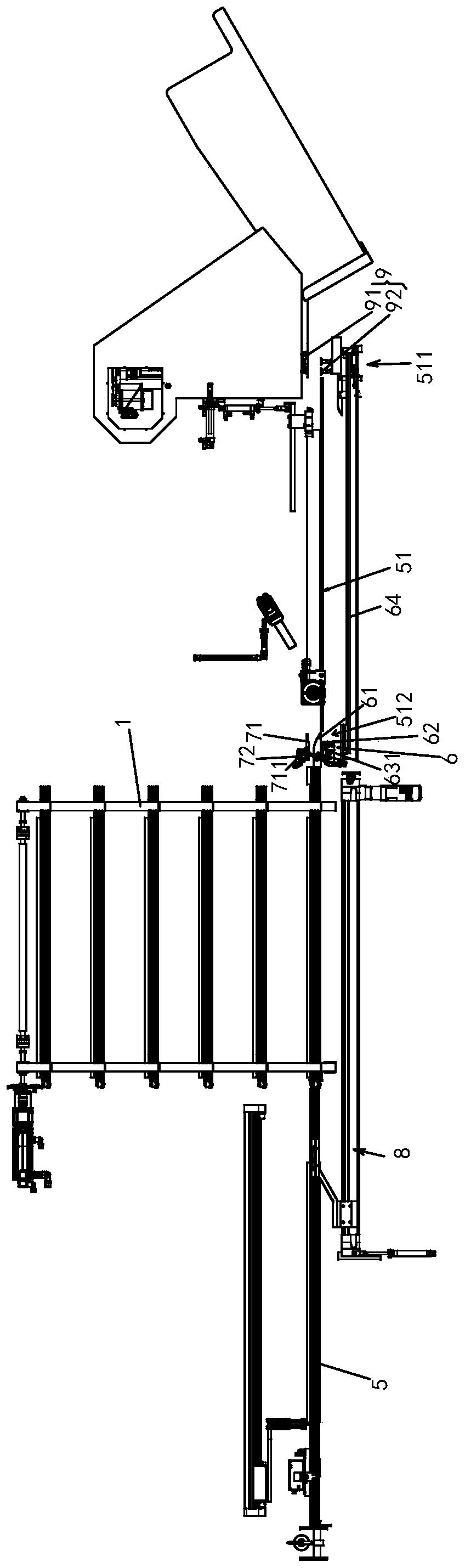

[0054] Embodiment two: see Figure 1-11 Shown:

[0055] A packaging device for the lid of the pop-top can, comprising a frame 4, and a lid rail 5 provided on the frame 4 for transporting stacked lids, the lid rail 5 is connected in series with the The temporary storage device for pop-top can lids, and specifically, the track for placing the lids on the bottom layer of the temporary storage device for pop-top can lids is connected in series with the lid track 5 .

[0056] see figure 1 , 2 and Figure 8-11 As shown, a section of the cover track 5 located behind the temporary storage device for pop can covers in the conveying direction of the cover track 5 is used as a push cover bagging section 51, and one end of the push cover bag bag section 51 is used as a packaging bag The supply position 511, the other end is used as the cover body into the bag position 512.

[0057] A packaging bag positioning and opening assembly 9 is provided at the packaging bag supply position 511...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com