Mud-water separation device

A mud-water separation and barrel separation technology, which is used in water/sludge/sewage treatment, centrifuges, sludge treatment, etc. It can solve problems such as clogging of sewer pipes, small mesh holes in mesh screens, and blockage of sediment, and prevent Sediment blocking device, obvious separation effect, and the effect of improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

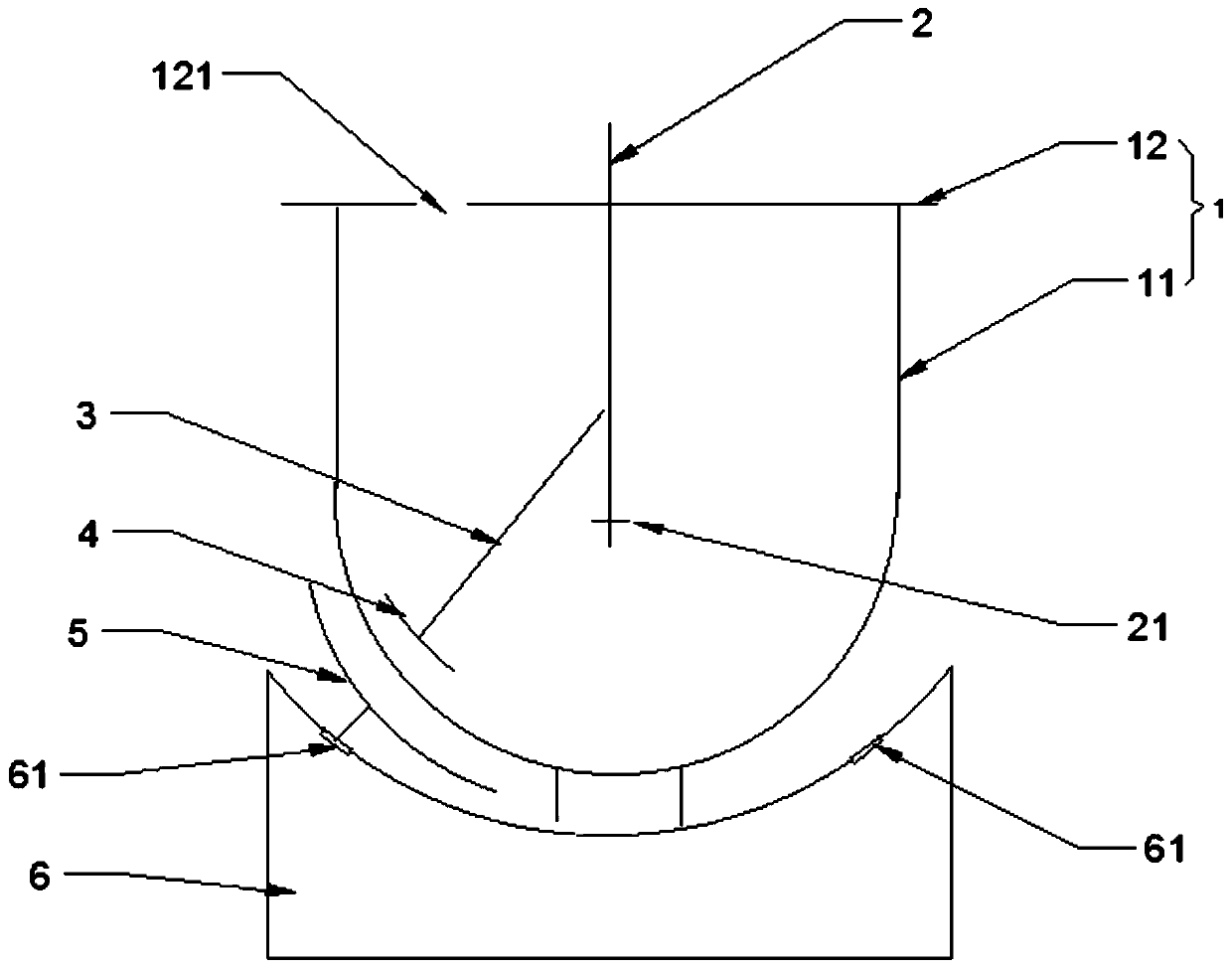

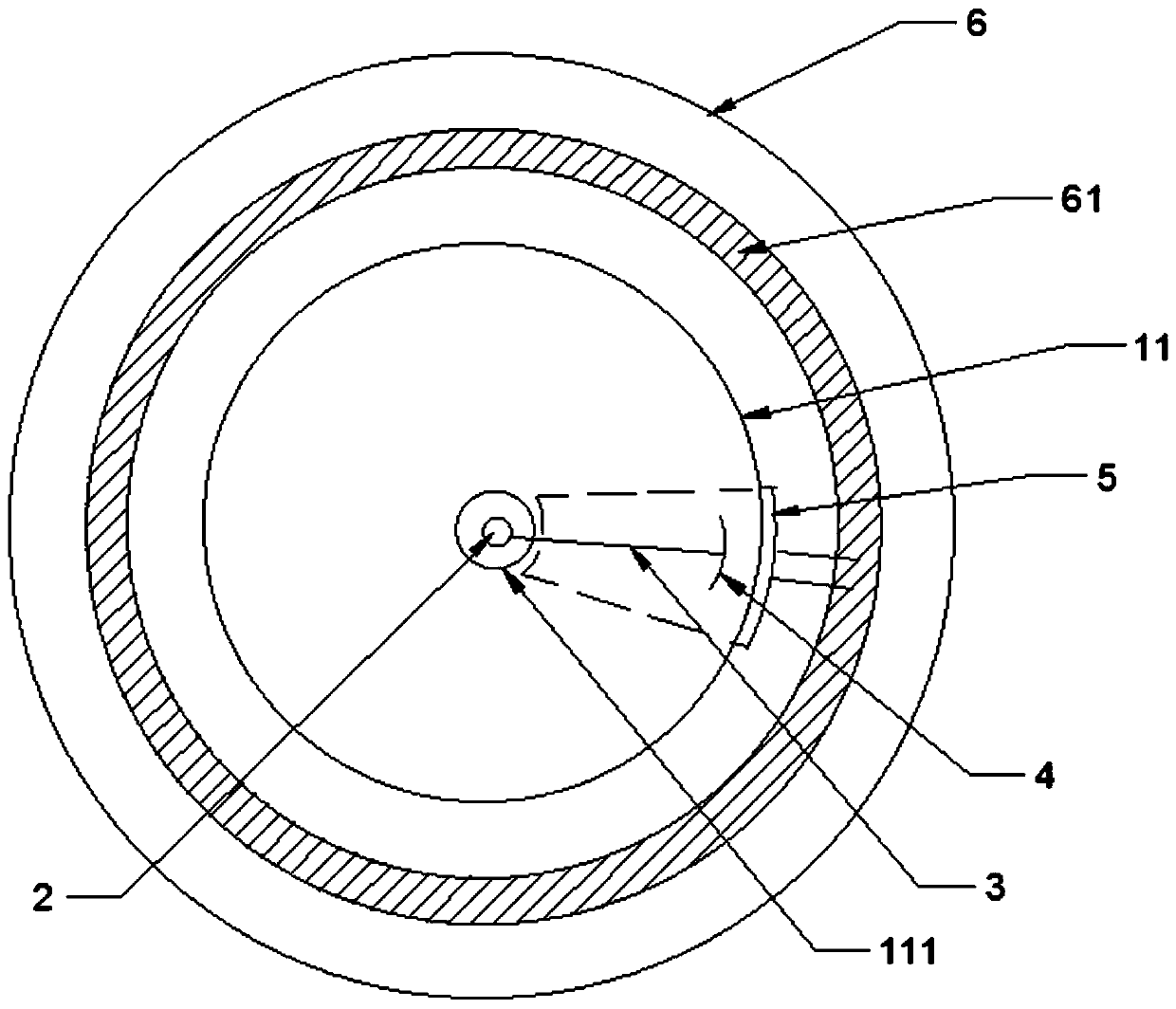

[0026] A mud-water separation device, through the magnetic force of the magnetic sheet 5, the iron sheet 4 in the separation barrel 1 is driven to rotate, so that a vortex is formed in the separation barrel 1, and the effect of sediment separation is improved. Chance of clogging the device.

[0027] Such as Figure 1 ~ Figure 2 As shown, the mud-water separation device in the present embodiment includes a separation barrel 1, and the separation barrel 1 includes a barrel body 11 and a barrel cover 12, and the barrel body 11 and the barrel cover 12 can be welded and fixed to each other, or can be set as The detachable lid is closed, and when the clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com