The firing method of Jianzhan with color drop and gold edge

A color bottom and green body technology, which is applied in the firing field of color-bottom color-drop gilt-edged lamps, can solve the problems of unclear formula selection and temperature control, dry and gray lips, and difficulty in preparing oil droplets, etc. Artistic value and appreciation value, easy to control, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

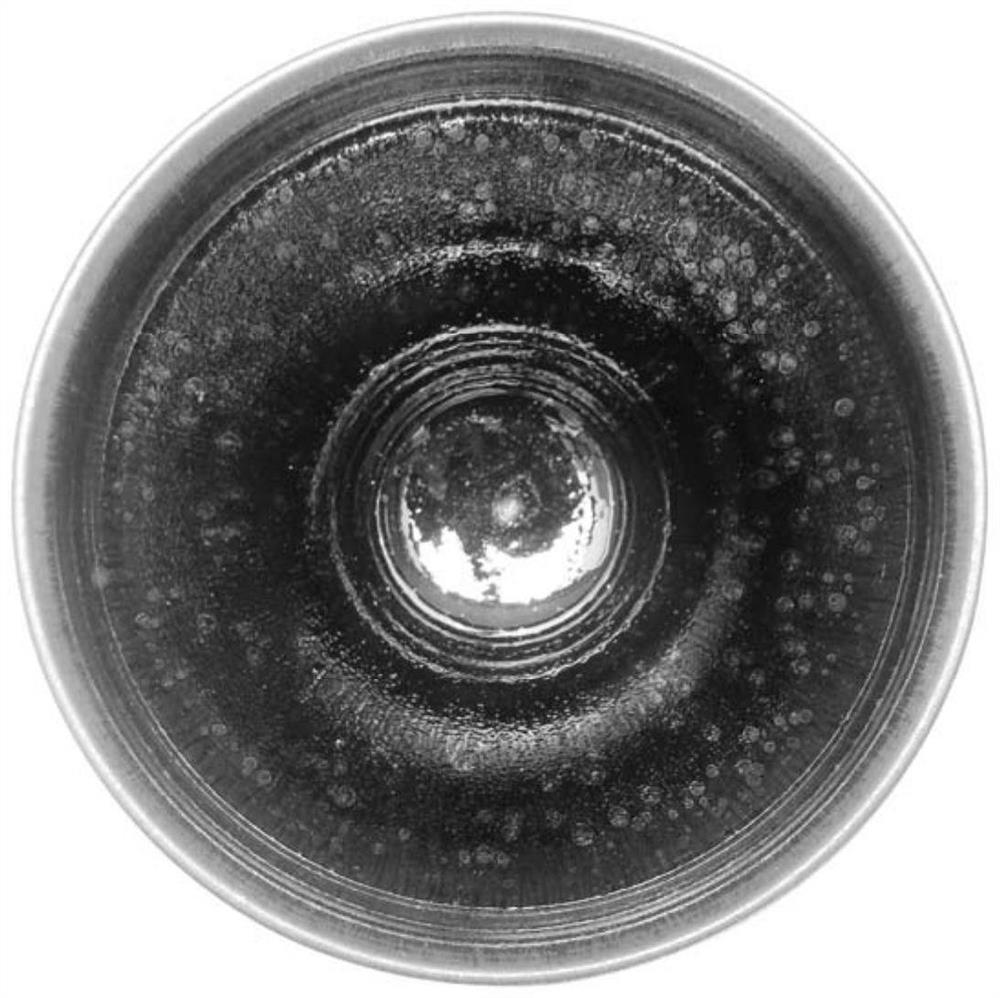

Image

Examples

Embodiment 1

[0033] The firing method of the color bottom color drop Phnom Penh jian cup includes the following steps:

[0034] (1) Preparation of raw materials and glazes for the blank;

[0035] The raw material of the body is prepared by the following method: 65 parts of kaolin, 25 parts of laterite by weight, 10 parts of the field soil mixed, crushed, washed, through 60 mesh sieve, press filtered, put into a wooden barrel for 3 months, and then refined, and then filled with plastic bags for 6 months;

[0036] The glaze paste is prepared by the following method: 75 parts of the glaze stone and water are mixed in a 1:1 ratio, ground into a pulp, the laterite of 5 parts by weight, the cone chestnut ash of 2 parts by weight, the potassium feldspar of 13 parts by weight, the limestone of 10 parts by weight into the ball mill with water into a pulp, the two kinds of pulp are mixed, and then the glaze pulp is obtained by 200 mesh sieve, and the glaze pulp concentration is adjusted to 49 ° Bé (the ...

Embodiment 2

[0052] The firing method of the color bottom color drop Phnom Penh jian cup includes the following steps:

[0053] (1) Preparation of raw materials and glazes for the blank;

[0054] The raw material of the blank is prepared by the following method: 70 parts of kaolin, 23 parts of laterite by weight, 9 parts of the field soil mixed, crushed, washed, through a 60 mesh sieve, filtered, put into a wooden barrel for 3 months, and then refined, and then filled with plastic bags for 6 months;

[0055]The glaze paste is prepared by the following method: 75 parts of the glaze stone and water are mixed in a 1:1 ratio, ground into a pulp, the laterite of 5 parts by weight, the cone chestnut ash of 2 parts by weight, 13 parts of potassium feldspar by weight, 10 parts of the limestone by weight into a ball mill with water into a pulp, the two kinds of pulp are mixed, and then the glaze pulp is obtained by 200 mesh sieve, and the glaze concentration is adjusted to 46 ° Bé (the glaze pulp tempe...

Embodiment 3

[0070] The firing method of the color bottom color drop Phnom Penh jian cup includes the following steps:

[0071] (1) Preparation of raw materials and glazes for the blank;

[0072] The raw material of the blank is prepared by the following method: 60 parts of kaolin, 26 parts of laterite by weight, 8 parts of the field soil mixed, crushed, washed, through 60 mesh sieve, filtered, put into a wooden barrel for 4 months, and then refined, and then filled with plastic bags for 7 months;

[0073] The glaze paste is prepared by the following method: 75 parts of the glaze stone and water are mixed in a 1:1 ratio, ground into a pulp, the laterite of 5 parts by weight, 2 parts by weight of cone chestnut ash, 13 parts of potassium feldspar by weight, 10 parts of limestone by weight into a ball mill with water into a pulp, the two kinds of pulp are mixed, and then the glaze pulp is obtained by 200 mesh sieve, and the glaze pulp concentration is adjusted to 50 ° Bé (the glaze pulp temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com