Method for preventing grouting hollowing in steel structure base

A steel structure, hollowing technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems that affect the strength and quality of the steel structure base, high-strength grouting material pouring into the hollowing, and it is difficult to ensure that the grouting material is dense, etc., to achieve ideas and methods Clear, low cost, avoid rework effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

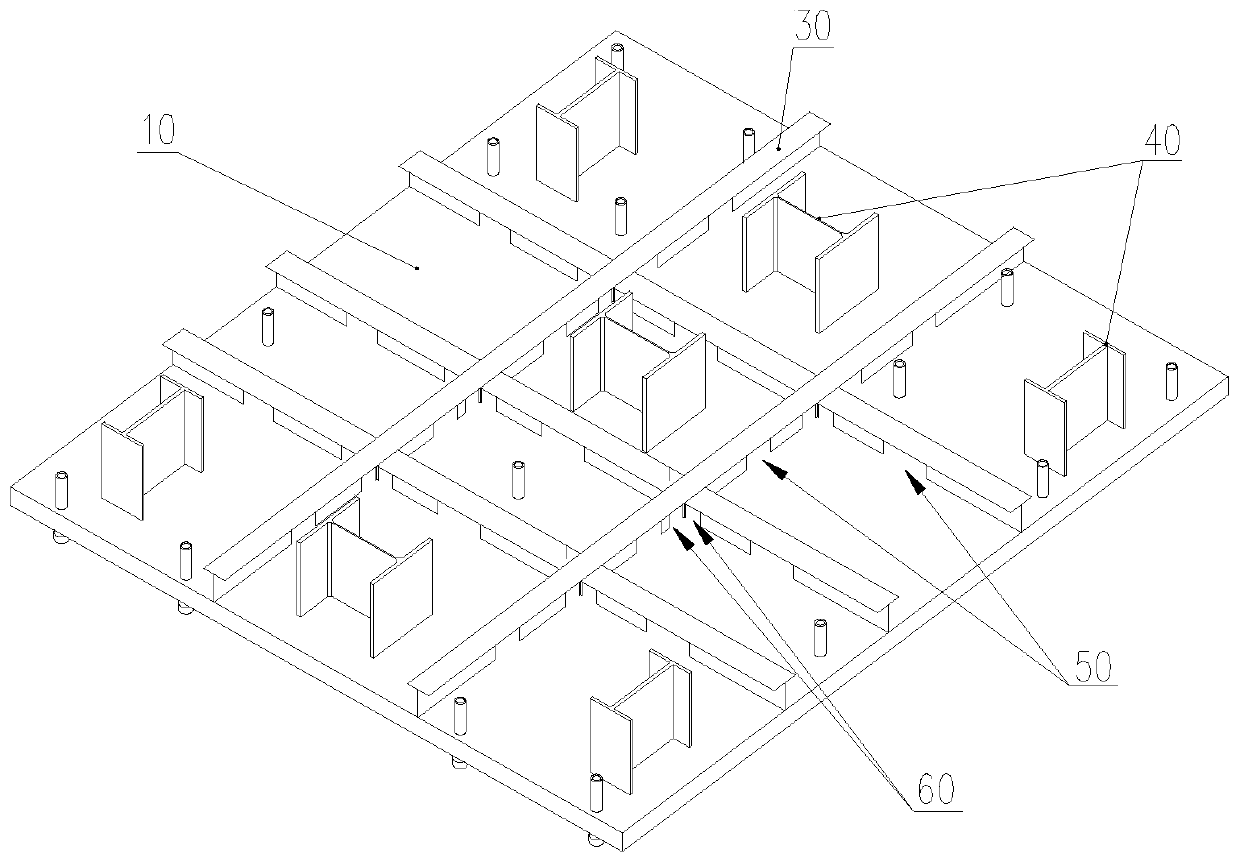

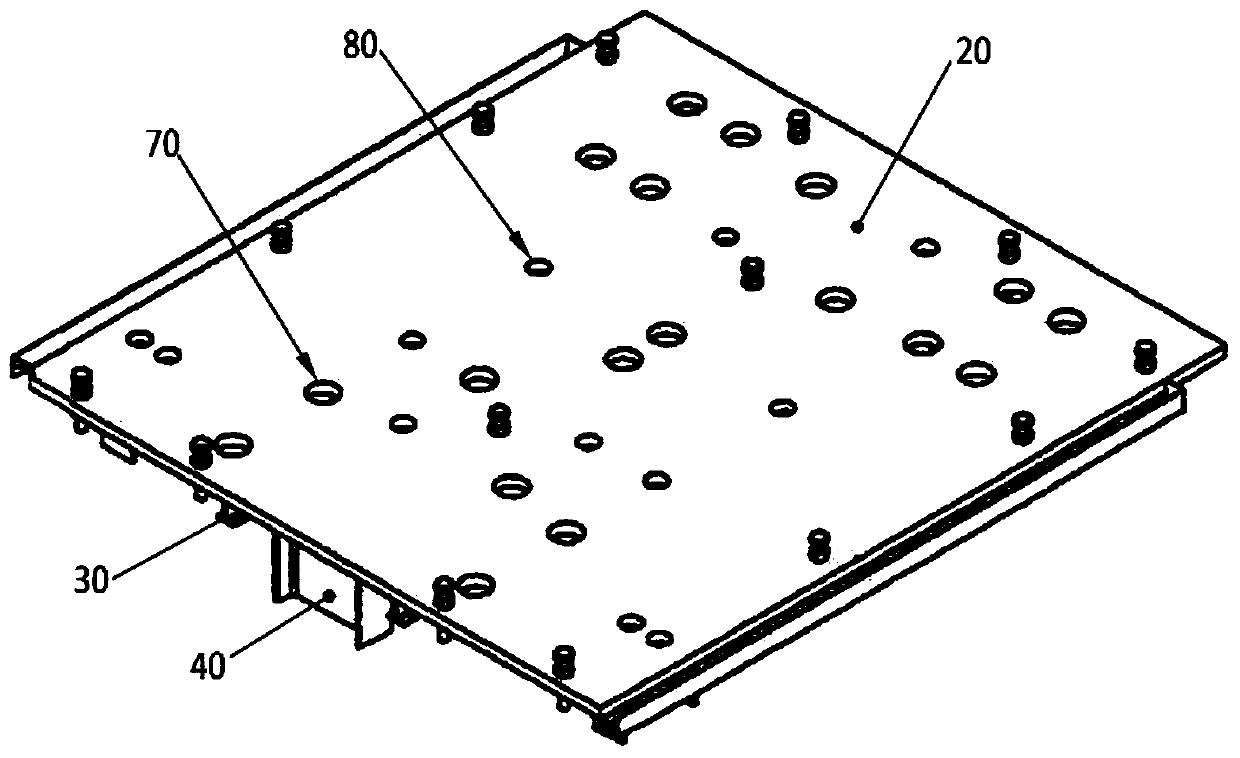

[0043] like figure 1 Schematic diagram of the structure of the steel plate at the bottom of the steel structure box in a method for preventing grouting hollowing inside the steel structure base provided by the embodiment of the present invention, figure 2 A schematic diagram of the structure of the top steel plate of the steel structure box in a method for preventing grouting hollowing inside the steel structure base provided by the embodiment of the present invention:

[0044] A method for preventing hollow grouting inside a steel structure base;

[0045] The steel structure base includes a steel structure box formed by combining the bottom steel plate 10 and the top steel plate 20. Inside the steel structure box is a high-strength grout that needs to be densely poured. The bottom steel plate 10 is laid and fixed on the reinforced concrete foundation structure layer, and the top layer The upper surface of the steel plate 20 is used for installing and carrying other equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com