Waterproof structure adopting combined steel-edged rubber water stop and construction method thereof

A rubber waterstop and waterproof structure technology, applied in underwater structures, infrastructure engineering, water conservancy engineering and other directions, can solve the problems of water leakage, cracking, no cracks, etc., to facilitate positioning and installation, improve waterproofing performance, the effect of extending the water seepage path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

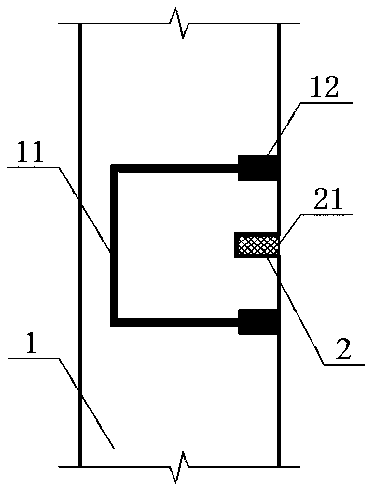

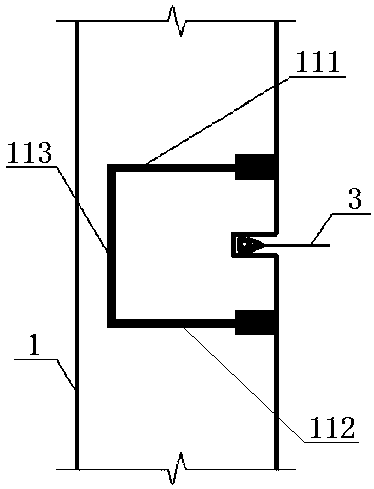

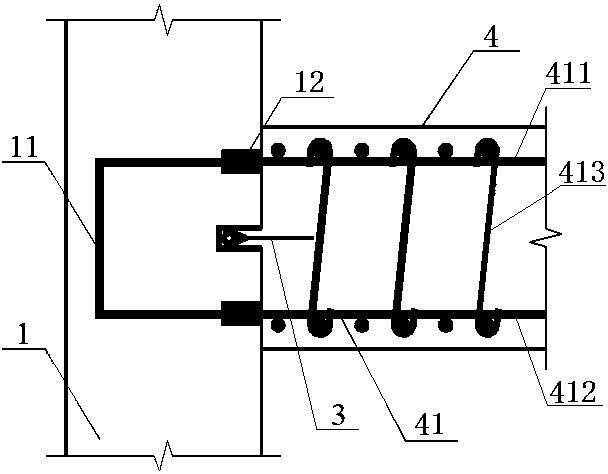

[0033] Such as Figure 1-Figure 4 As shown, this embodiment provides a waterproof structure using a combined steel-edged rubber waterstop, including a pre-concrete structure 1, a post-concrete structure 4 and a combined steel-edged rubber waterstop 3; the pre-concrete structure 1 and the post-concrete structure Make the positioning connection of the concrete structure 4, and the steel plate groove 2 with the opening facing the rear concrete structure 4 is pre-embedded on the concrete structure 1 in advance; the combined steel edge rubber waterstop 3 includes a rubber strip 31 and a steel strip 32, and the rubber strip 31 is installed In the steel plate groove 2, the steel plate groove 2 and the rubber strip 31 are arranged along the construction joint between the pre-concrete structure 1 and the post-concrete structure 4; one end of the steel plate strip 32 is embedded in the rubber strip 31, and the other end is placed in the post-concrete structure 4 Inside. In this embodim...

Embodiment 2

[0040] Such as Figure 1-Figure 4 As shown, this embodiment provides the construction method of the waterproof structure using the combined steel edge rubber waterstop in the above embodiment, including the following steps:

[0041] 1) Determine the thickness of the post-concrete structure 4 and the reinforcement requirements for the steel skeleton 41 of the post-concrete structure 4 according to the structural calculation;

[0042] 2) Construct the pre-concrete structure 1, and during the construction of the pre-concrete structure 1, pre-embed the steel plate groove 2 in the pre-concrete structure 1, and at the same time fill the steel plate groove 2 with filler 21 temporarily to prevent concrete from blocking the steel plate groove 2;

[0043] 3) After completing the construction of the pre-concrete structure 1, according to the needs of the post-concrete structure 4, break the enclosure structure or remove the formwork to provide construction space; then according to the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com