A test simulation method for the bearing capacity of vertical support columns under the construction environment of reverse construction

A technology of construction environment and vertical support, which is applied in the test of foundation structure, foundation structure engineering, construction, etc., can solve the problem that the construction method of deep foundation pit is difficult to adapt to the development conditions, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

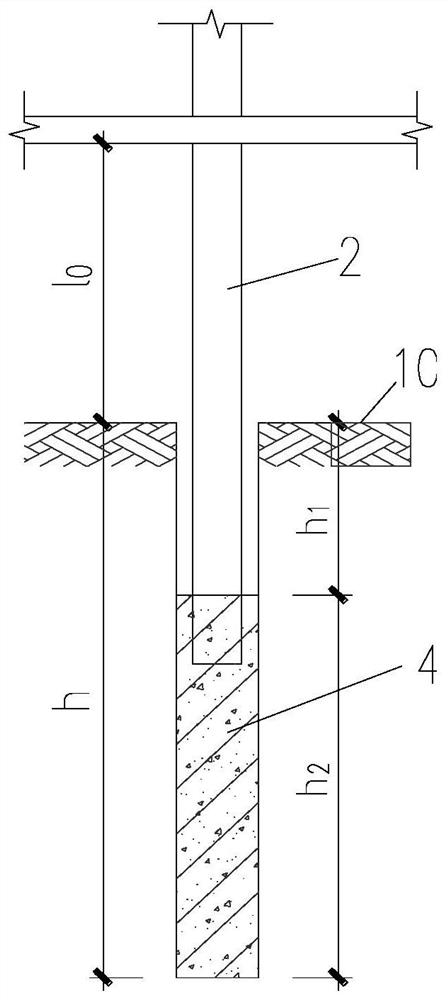

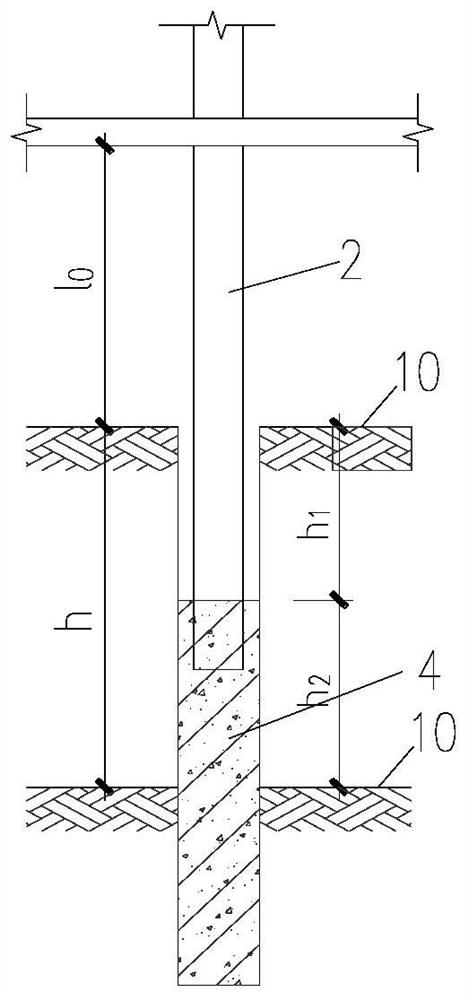

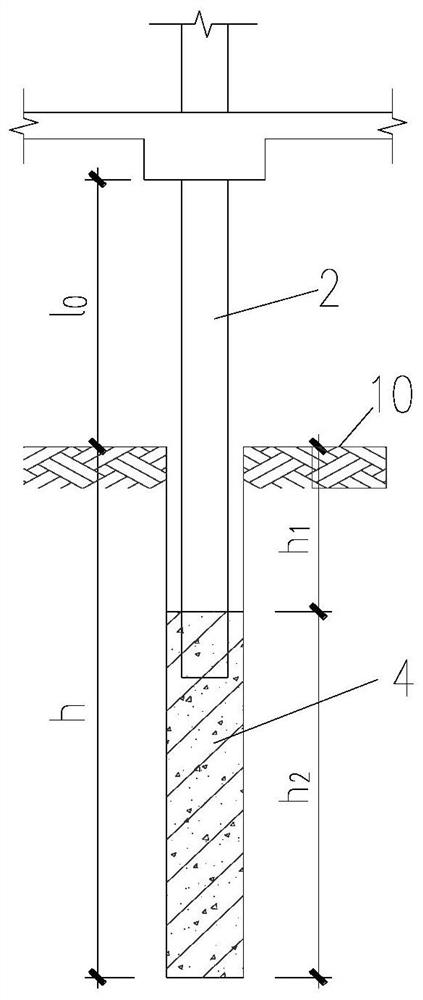

[0061] Calculation length L of steel pipe concrete column under constraint conditions c And a method for calculating the calculation of the steel tube concrete column 2 c The calculation formula is as follows:

[0062]

[0063] The steel pipe concrete column 2 includes a steel pipe and a concrete pouring in the steel pipe, and the actual pile 4 is formed by a steel and piles of concrete 42. For convenience of calculation, steel pipe concrete column 2 is calculated as an equivalent pile. l c For the calculation length (m) of the steel pipe concrete column 2; μ is the calculation length coefficient of the column end constraint condition of the steel pipe concrete column 2, and the constraint conditions include fixed, hinged, semi-rigid connections. When the steel tube concrete column 2 is hinged, 1.0 is hinged, and when one end is fixed, 0.7 is fixed, and 0.5 is fixed at both ends. 0 The exposed length of the steel pipe concrete column 2; H 1 , H 2 The length of the steel pipe con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com