Turbine power generation equipment

A technology of turbine power generation and equipment, applied in wind power generation, mechanical equipment, engines, etc., can solve problems such as the decline in power generation efficiency of turbine generators, and achieve the effect of avoiding difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

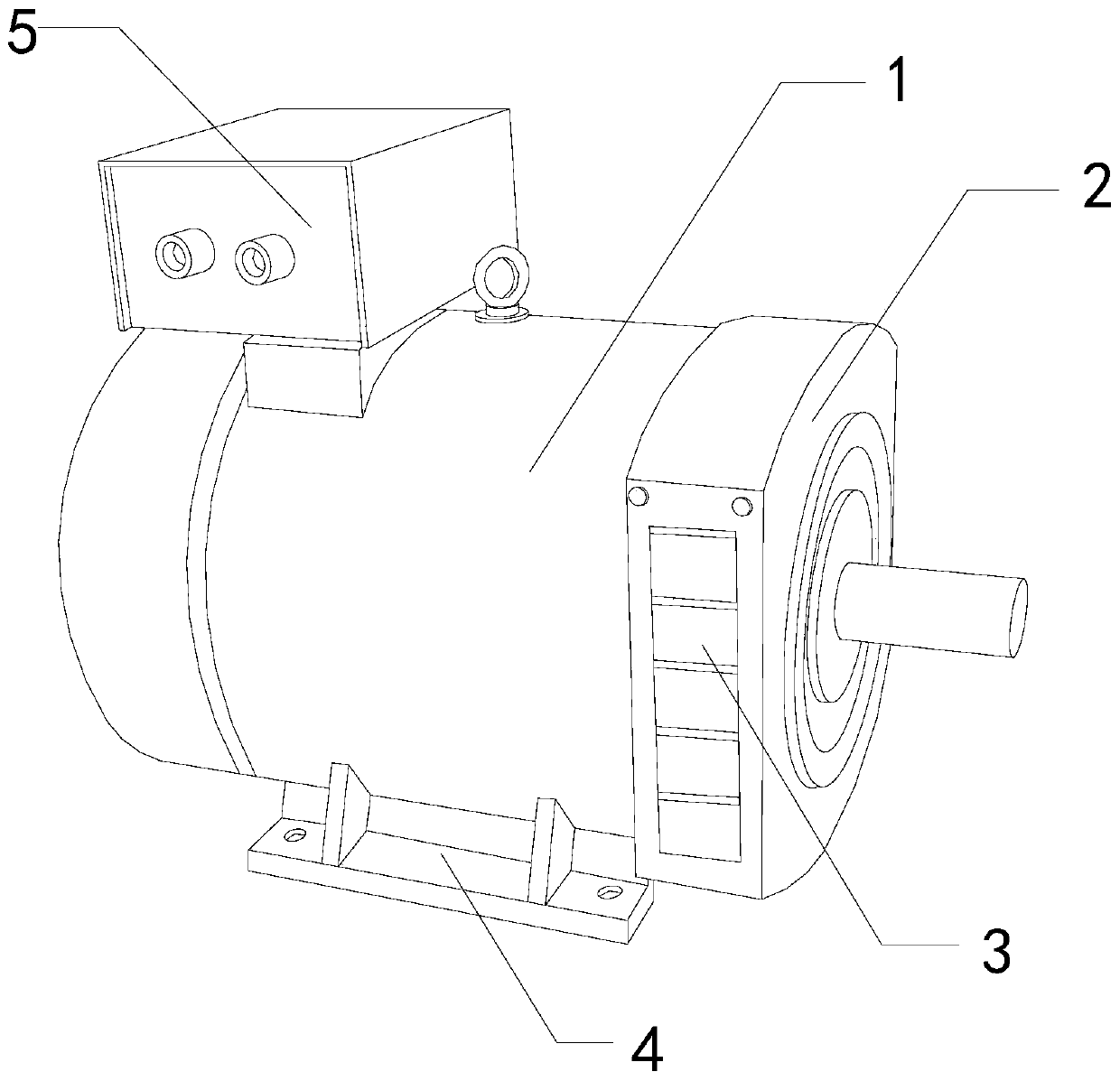

[0027] The invention provides a turbine power generation equipment, the structure of which includes a generator 1, a turbine mechanism 2, an air vent 3, a base 4, and a connection box 5. The turbine mechanism 2 is embedded in the right end of the generator 1, and the base 4 is welded at the bottom of the generator 1, the electrical connection box 5 is installed at the upper end of the generator 1, and the vent 3 and the turbine mechanism 2 are an integrated mechanism.

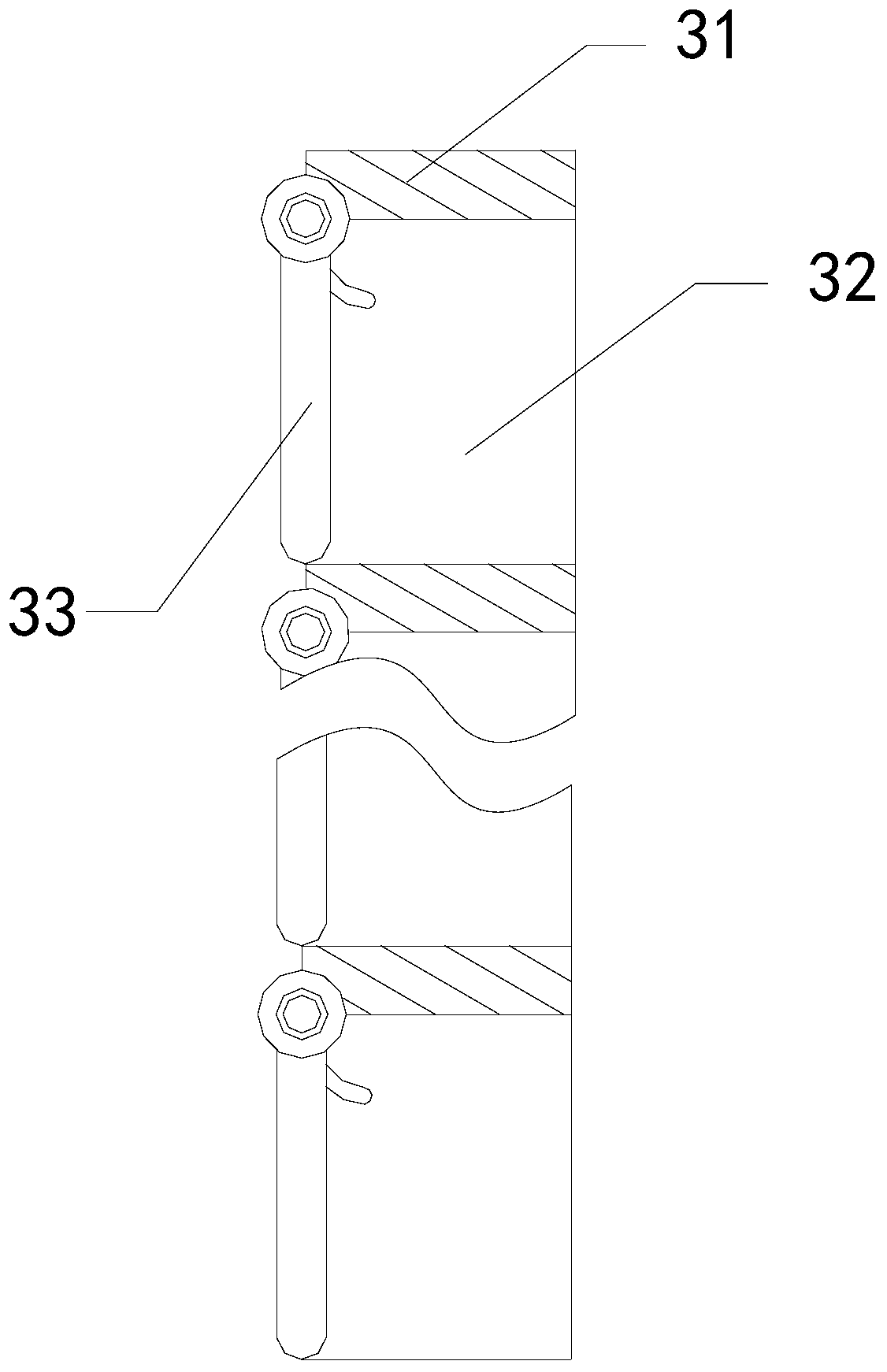

[0028] Wherein, the air vent 3 includes a frame body 31, an exhaust cavity 32, and a swing plate 33, the exhaust cavity 32 and the frame body 31 are an integrated structure, and the swing plate 33 is hingedly connected with the frame body 31, when there is The airflow pushes the swinging plate 33 outwards through the exhaust chamber 32 so that it can swing upwards, so that the airflow can be discharged. When the thrust of the airflow is lost, the swingin...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

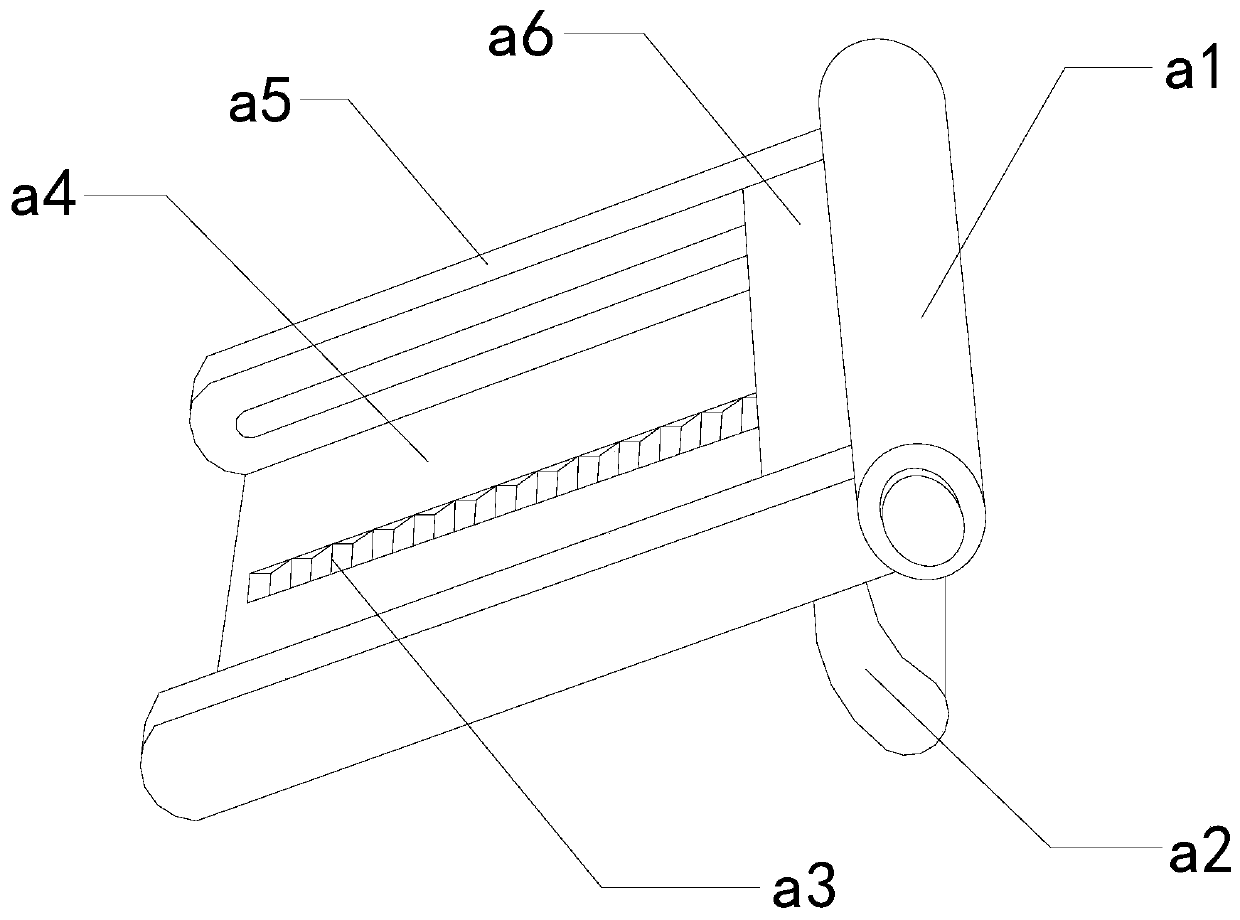

[0035]Wherein, the protection surface a3 includes a opening and closing plate a31, a sliding block a32, a fixed rod a33, a transmission rod a34, and a connecting rod a35. The sliding block a32 is in clearance fit with the opening and closing plate a31. Between the plywood a31, one end of the transmission rod a34 is connected with the left end of the fixed rod a33, and the other end of the transmission rod a34 is movably engaged with the left end of the connecting rod a35, and the connecting rod a35 is hingedly connected with the sliding block a32, There are two fixed rods a33, which are symmetrically distributed on the inner side of the opening and closing plate a31. When the opening and closing plate a31 is folded and closed by external force, the transmission rod a34 can be closed synchronously, so that the sliding block on the connecting rod a35 a32 can be attached to the inner side of the opening and closing plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com