Measuring system and method for mechanical quality factor of vibrating body

A technology of mechanical quality factor and measurement method, which is applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve the problems of low measurement accuracy and inability to measure at the same time, achieve simple calculation process, suppress adverse effects, reduce The effect of a small number of measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

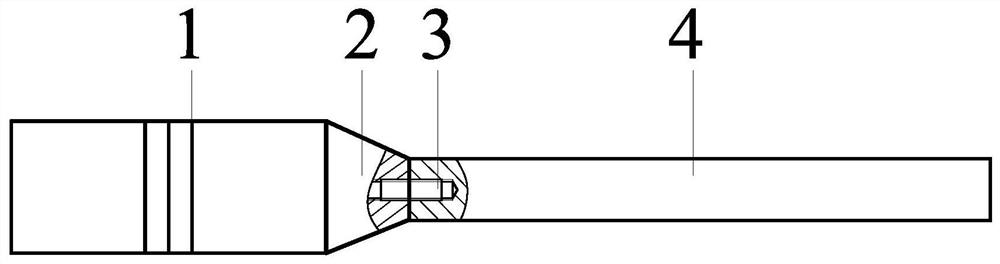

[0043] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

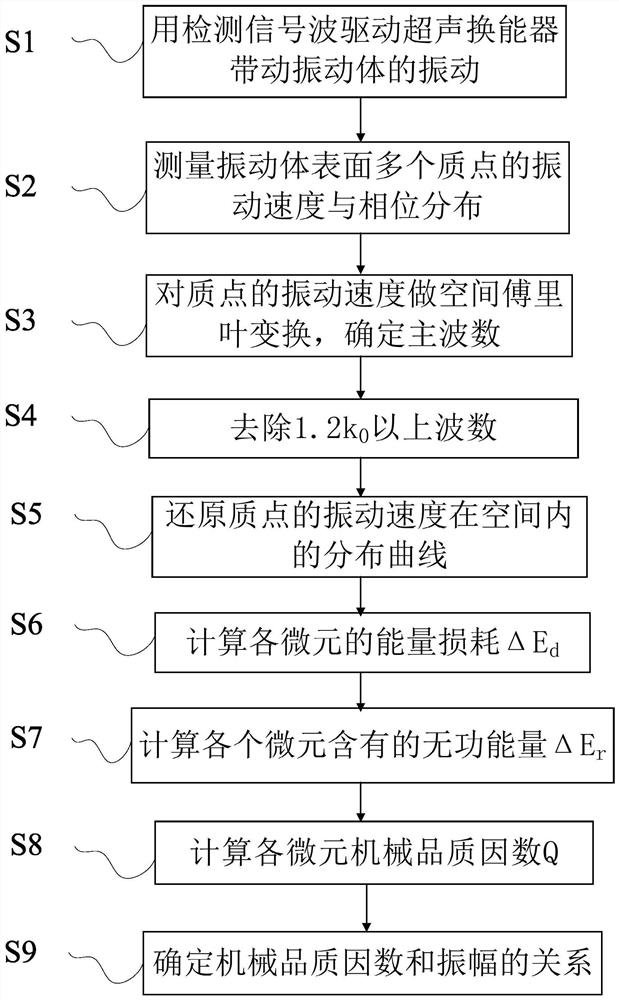

[0044] The mechanical quality factor Q of the vibrating body 4 represents the energy consumed by overcoming internal friction when the vibrating body 4 resonates, and is an important parameter to measure the performance of the material. Such as Figure 2-Figure 3 The method for measuring the mechanical quality factor of the invention shown is as follows:

[0045] S1, using the detection signal wave to drive the ultrasonic transducer 1 to drive the vibration body 4 to vibrate.

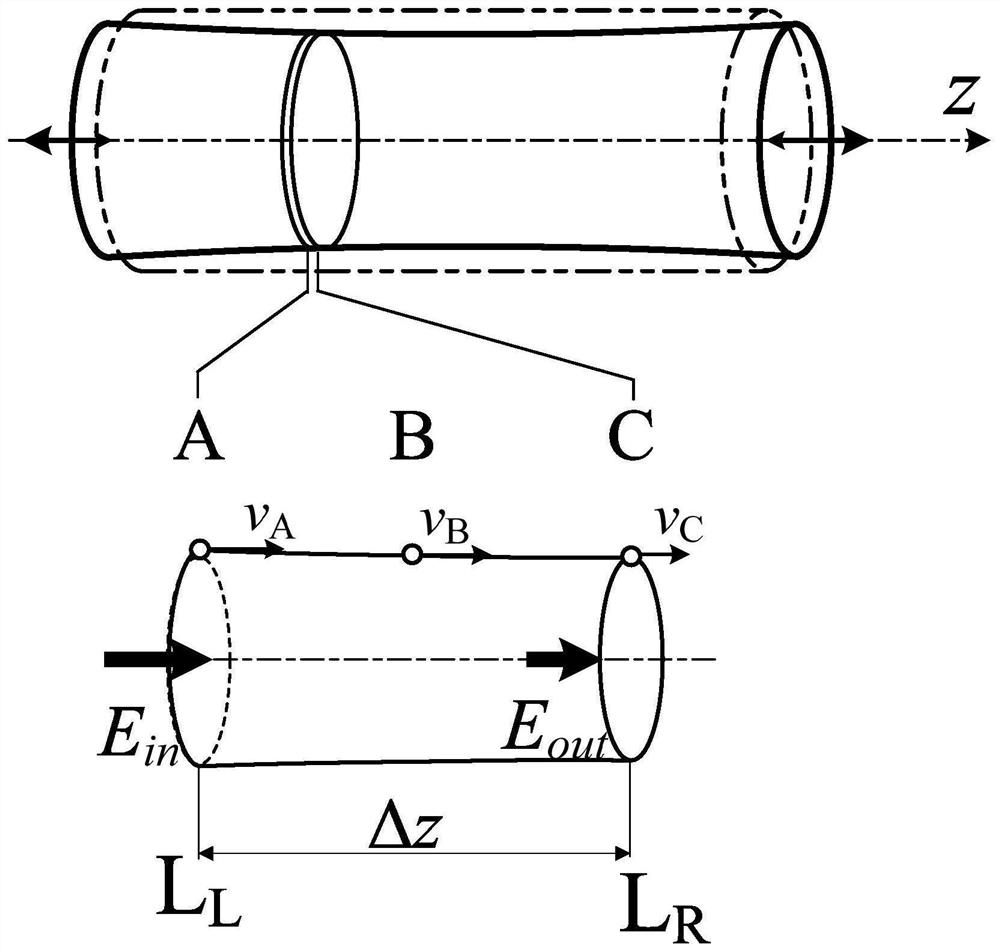

[0046] S2, move the vibration measuring device 7 along the axial direction of the vibrating body 4, and measure the vibration velocity and phase of multiple particles of the ΔZ micro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com