Conveying device for cable pipe-penetrating laying and cable pipe-penetrating laying method

A technology of conveying device and cable, which is applied in cable laying equipment, cable installation device, cable installation and other directions, can solve the problems of large occupied space, high cost, difficult construction, etc., to reduce side pressure, reduce main traction, reduce effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

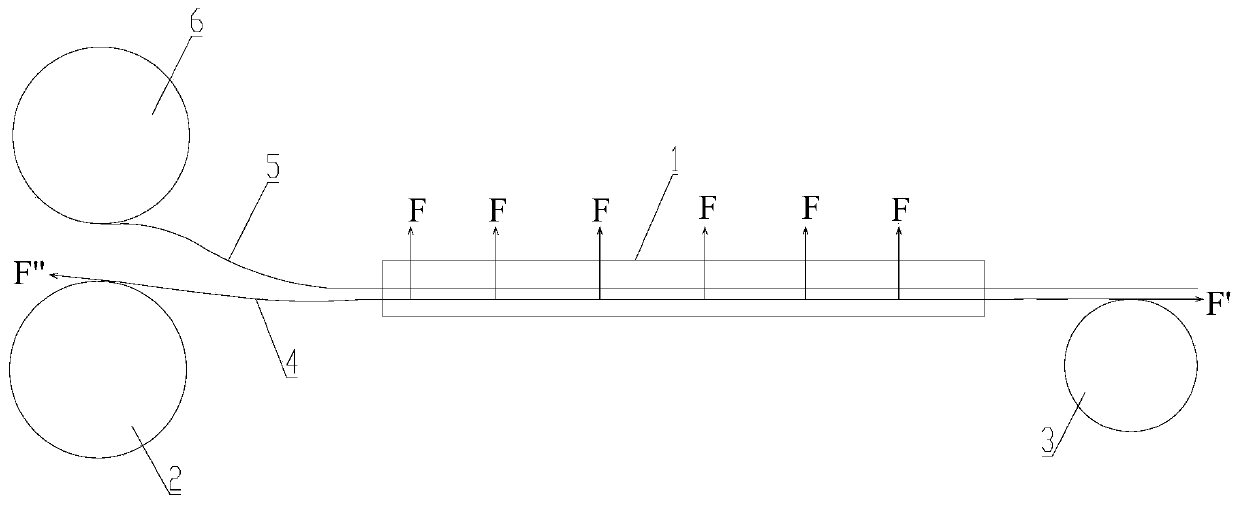

[0043] Such as figure 1 with figure 2 As shown, the first embodiment provides the first embodiment of the conveying device for laying cables through pipes of the present invention.

[0044] see figure 1 , The conveying device for cable pipe laying in the first embodiment includes a pay-off machine 2 , a take-up machine 3 and a conveyor belt 4 . Wherein, the pay-off machine 2 is placed at the entrance of the pipe 1, the pipe 1 is for the cable 5 to be laid to pass, the cable 5 to be laid is wound on the cable reel 6, and the cable reel 6 is placed at the entrance of the pipe 1, The cable 5 on the cable reel 6 can enter the pipe 1 from the entrance of the pipe 1 and protrude from the outlet of the pipe 1 after passing through the pipe 1 to realize the laying of the cable 5 through the pipe. The pay-off machine 2 accommodates the conveyor belt 4 in the initial state, and one end of the conveyor belt 4 is wound on the pay-off machine 2 . The take-up machine 3 is placed at the...

Embodiment 2

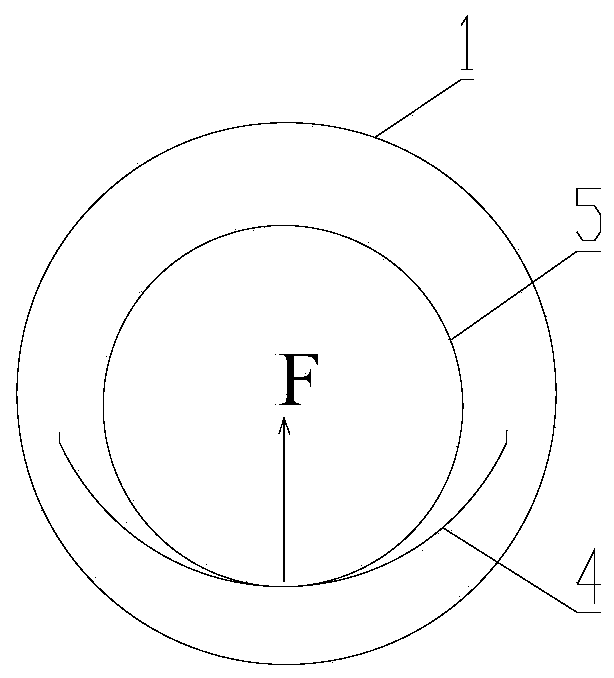

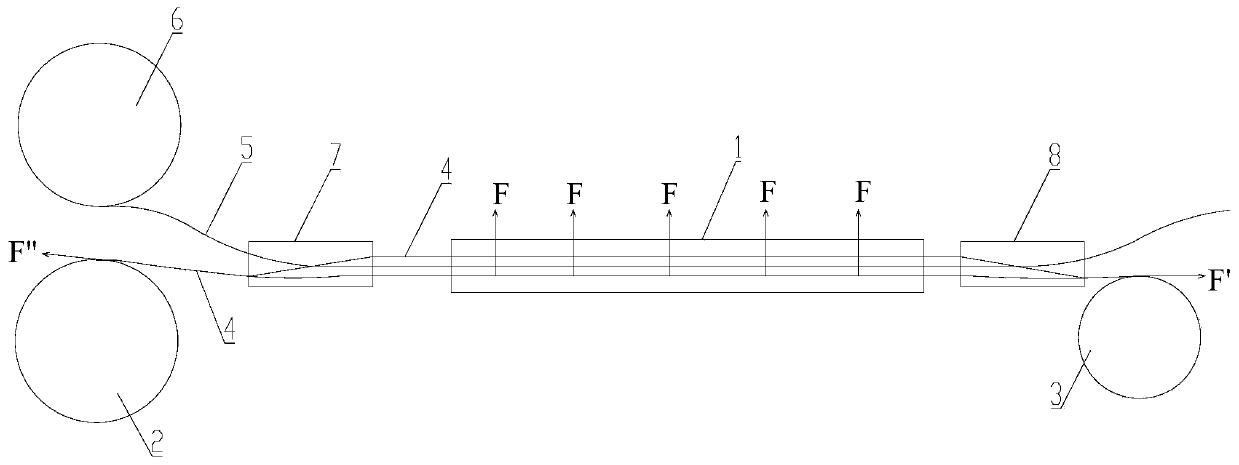

[0051] Such as Figure 3 to Figure 11 As shown, the second embodiment provides the second embodiment of the conveying device for laying cables through pipes of the present invention. The second embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that in the second embodiment, when the conveyor belt 4 is in contact with the cable 5, the cable 5 is partially or completely wrapped, thereby ensuring the transportation The stability of the belt 4 supporting the cables 5 enables the conveyor belt 4 to effectively drive the cables 5 through the pipe arrangement 1 together.

[0052] see Figure 4 , in the second embodiment, preferably, the conveyor belt 4 includes a first traction rope 41, a second traction rope 42 and a trawl net 43, and the first traction rope 41 and the second traction rope 42 are all connected to the take-up machine 3 and the pay-off machine 2. The trawl net 43 is fixed between the first traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com