A kind of barium stannate composite silica airgel powder and preparation method thereof

A technology of silica airgel and composite airgel, which is applied in the fields of airgel preparation, chemical instruments and methods, colloid chemistry, etc., and can solve the problems of large grain size and few research reports on nanocrystalline perovskite materials , to achieve the effect of stability and repeatability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

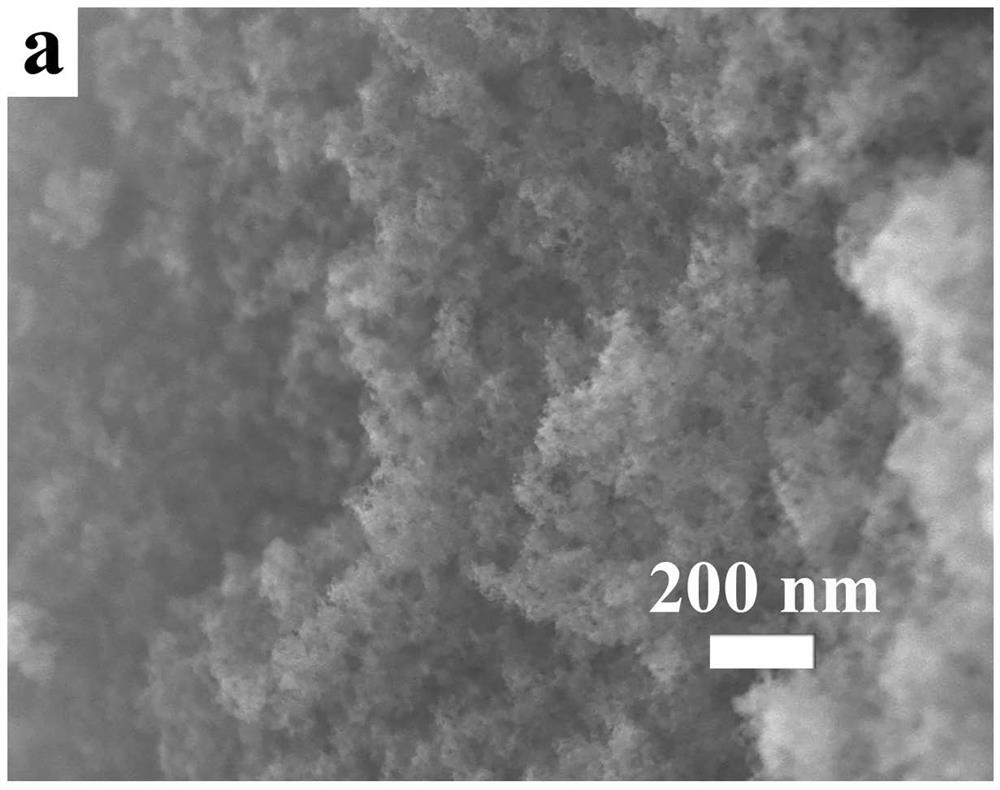

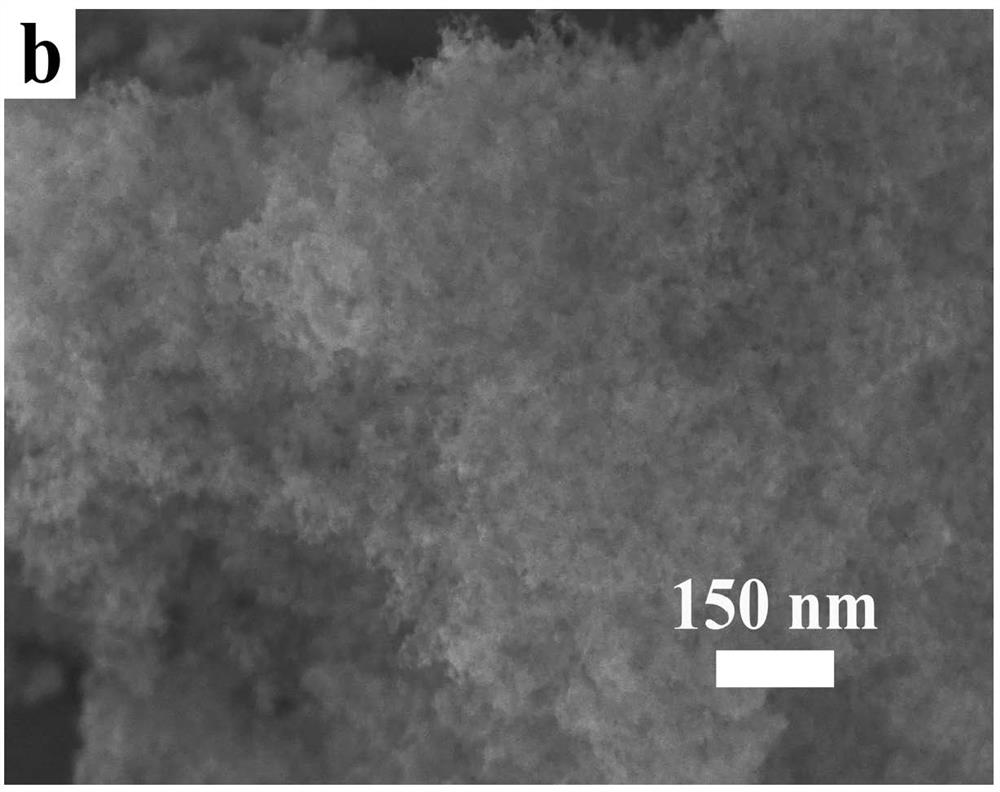

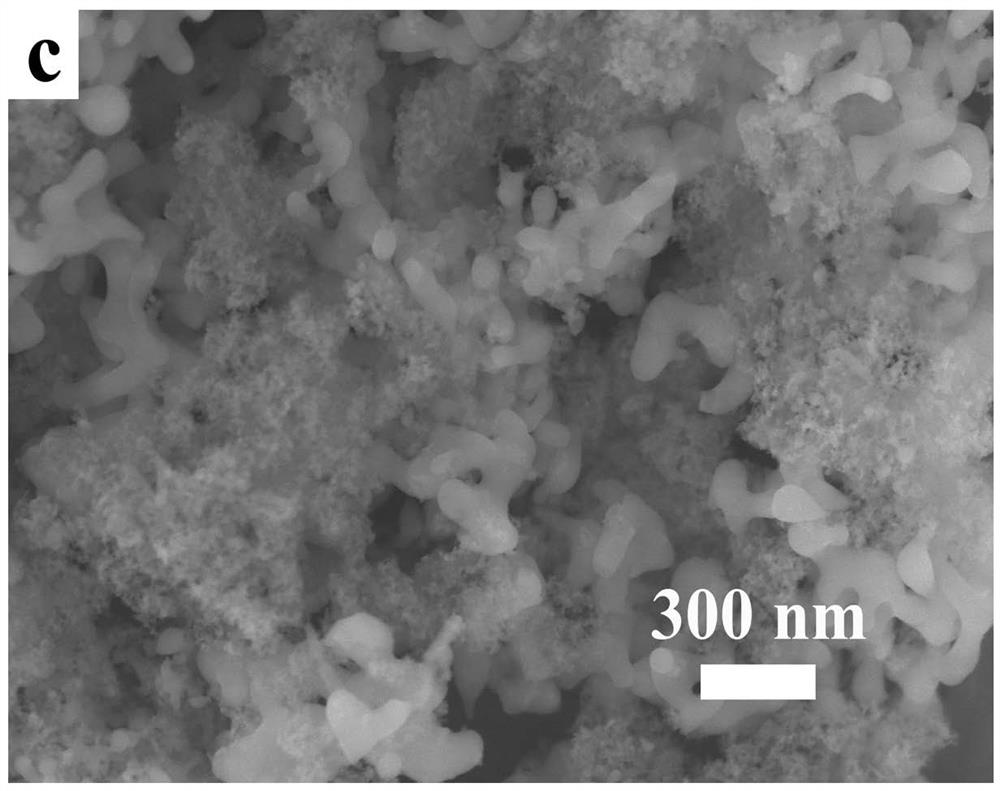

[0043] The application relates to an alkaline earth metal stannate composite airgel-barium stannate composite silicon oxide airgel and a preparation method thereof. The barium stannate composite silicon oxide airgel uses the silicon oxide airgel as a hard template, and the barium stannate nanoparticles are coated nanoparticles. Barium stannate nanoparticles can be uniformly distributed in the pores of silica airgel. Its preparation method can be peroxide co-precursor-sol-gel method, which can specifically include: using water-soluble tin salt, water-soluble barium salt, and chelating agent as raw materials, and using aqueous peroxide solution as solvent to prepare barium stannate precursor Mix it with the acidified silicic acid solution evenly, then adjust the pH of the solution to obtain a composite wet gel, then add a peroxide precipitant to prepare the barium stannate precursor powder, and then use an organic solvent with low surface tension Perform solvent replacement and...

Embodiment 1

[0062] Preparation of pure silica airgel

[0063] (1) Activation of cation exchange resin. Take 8.8ml of strongly acidic styrene cation exchange resin, wash it three times with deionized water, then add three times the volume of deionized water and stir at room temperature for 30 minutes to fully swell. Take 4ml of chemically pure concentrated hydrochloric acid, dissolve it in 26ml of deionized water at room temperature, and prepare 30ml of dilute hydrochloric acid with a concentration of 4-5%. Add the swollen cation exchange resin to dilute hydrochloric acid, stir and acidify for 2 hours, filter, wash, and set aside;

[0064] (2) Preparation of wet gel. Take 2ml industrial water glass (Na 2 SiO 3 ) was dissolved in 8ml deionized water at room temperature and diluted. Add the diluted water glass solution to the cation exchange resin in (1) to acidify for 20 minutes, then take out the supernatant, which is a silicic acid solution. Get 0.0235g hexamethylenetetramine (C 6 ...

Embodiment 2

[0074] Preparation of 93.5% SiO 2 +6.5% BaSnO 3 composite airgel

[0075] (1) Preparation of precursor solution. Take successively 0.02714g of barium chloride dihydrate (BaCl 2 2H 2 O), 0.039g of tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O) Dissolve in 2ml 30% hydrogen peroxide (H 2 o 2 ) aqueous solution, then add citric acid monohydrate (C 6 h 8 o 7 ·H 2 O), after stirring for 15 minutes, a clear precursor solution was obtained;

[0076] (2) Preparation of precursor wet gel. The precursor solution in (1) is mixed with the silicic acid solution in embodiment 1, gets 0.0235g hexamethylenetetramine (C 6 h 12 N 4) (the molar ratio of hexamethylenetetramine to silicon is 0.02) was dissolved in the mixed solution, the pH was adjusted to neutral, and it was placed in an oven at 70° C. for gelation. The gelled gel was aged in an oven at 50°C for 12 hours, then 1 mol / L ammonia solution was added dropwise until the pH value was 10, and finally reacted for 120 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com