High-efficiency coalbed methane extraction method by staged fracturing in multi-bottom horizontal wells in thin coal seam groups with large spacing

A technology of staged fracturing and horizontal wells, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of gas production reduction, single well gas production attenuation, collapse and buried drilling accidents, etc. The effect of reducing coalbed methane content and pressure, increasing coalbed aerodynamic reserves and accelerating construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The above-mentioned technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some, not all, embodiments of the present invention.

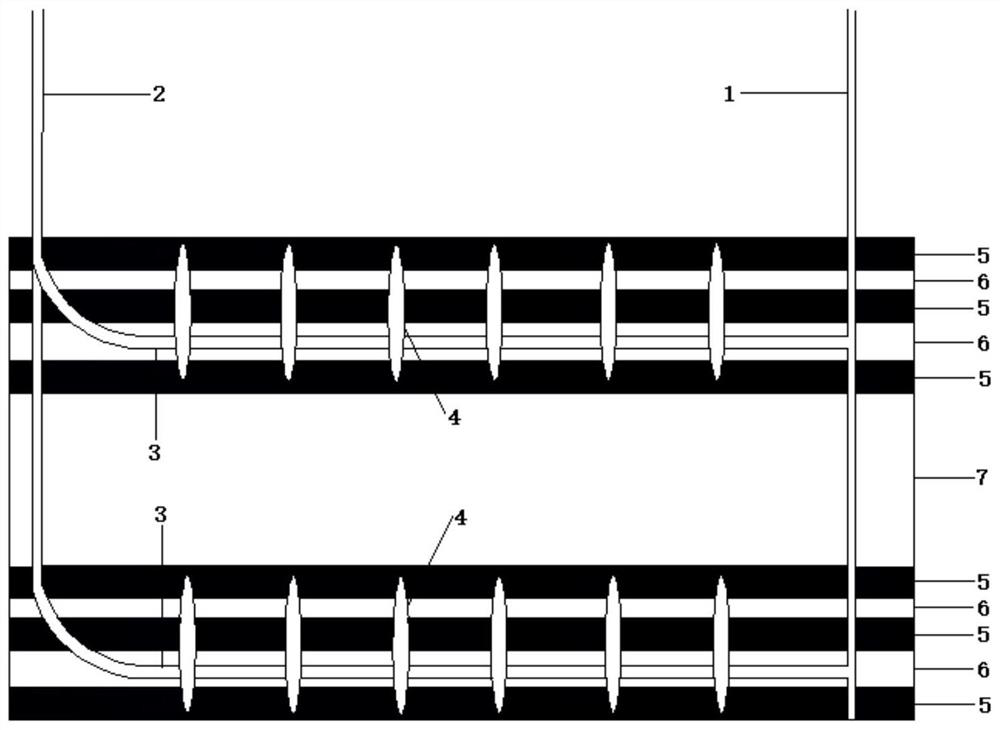

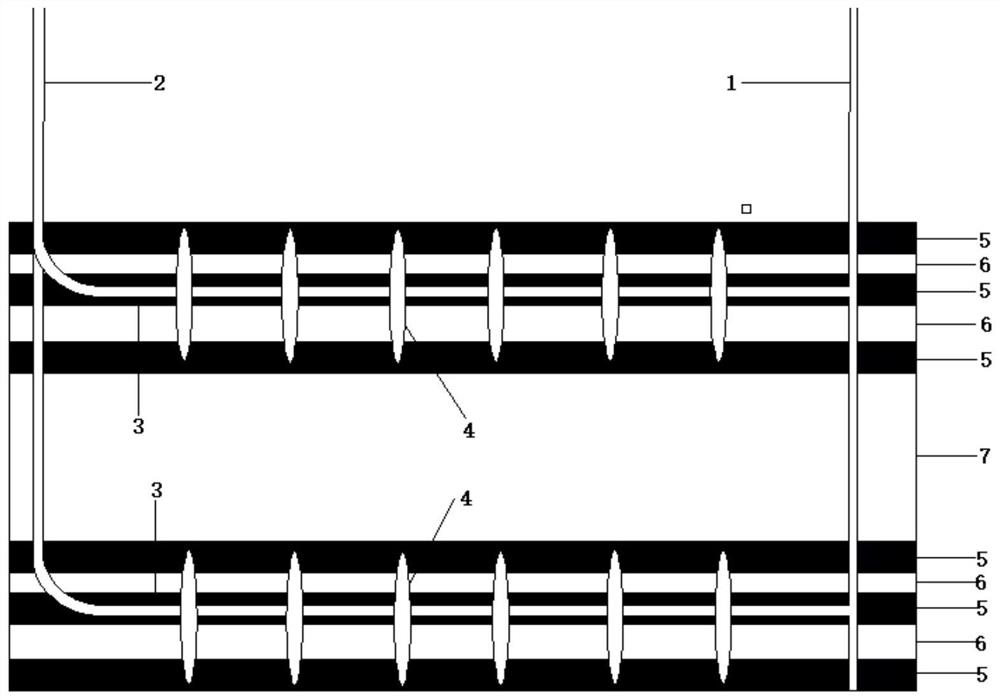

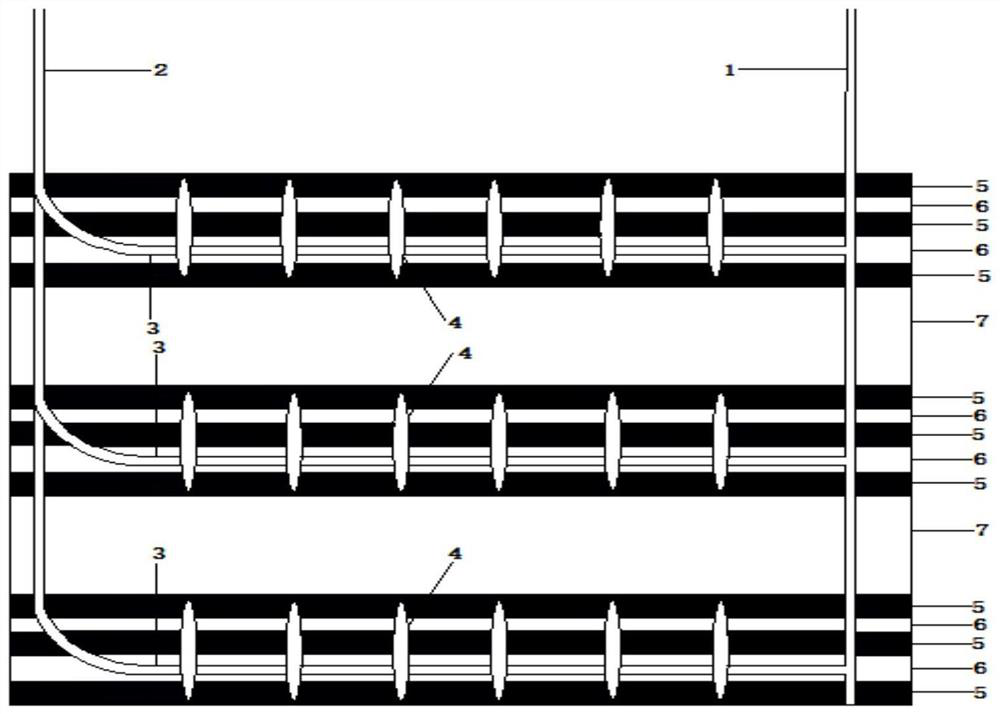

[0041] see Figure 1 to Figure 7 , the method for efficiently extracting coalbed methane by staged fracturing of multi-bottom horizontal wells in thin coal seam groups with large intervals comprises the following steps:

[0042] Step 1: Combining factors such as coal mining planning and coalbed methane resources, form 2-3 target production layer groups 8 in the intervals of enriched coal seams.

[0043] Specifically, the selection of the target production layer group 8 should be based on the relative enrichment and development degree of the coal seam, which should include factors such as thickness, number of layers, and spacing.

[0044] Step 2: According to the situation of the selected target prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com