Electronic detonator assembling and production unit line

An electronic detonator and electronic technology, which is applied in the field of electronic detonator assembly and production unit lines, can solve problems such as poor safety, low efficiency, and high labor intensity, and achieve the effects of short running distance, ensuring continuity, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

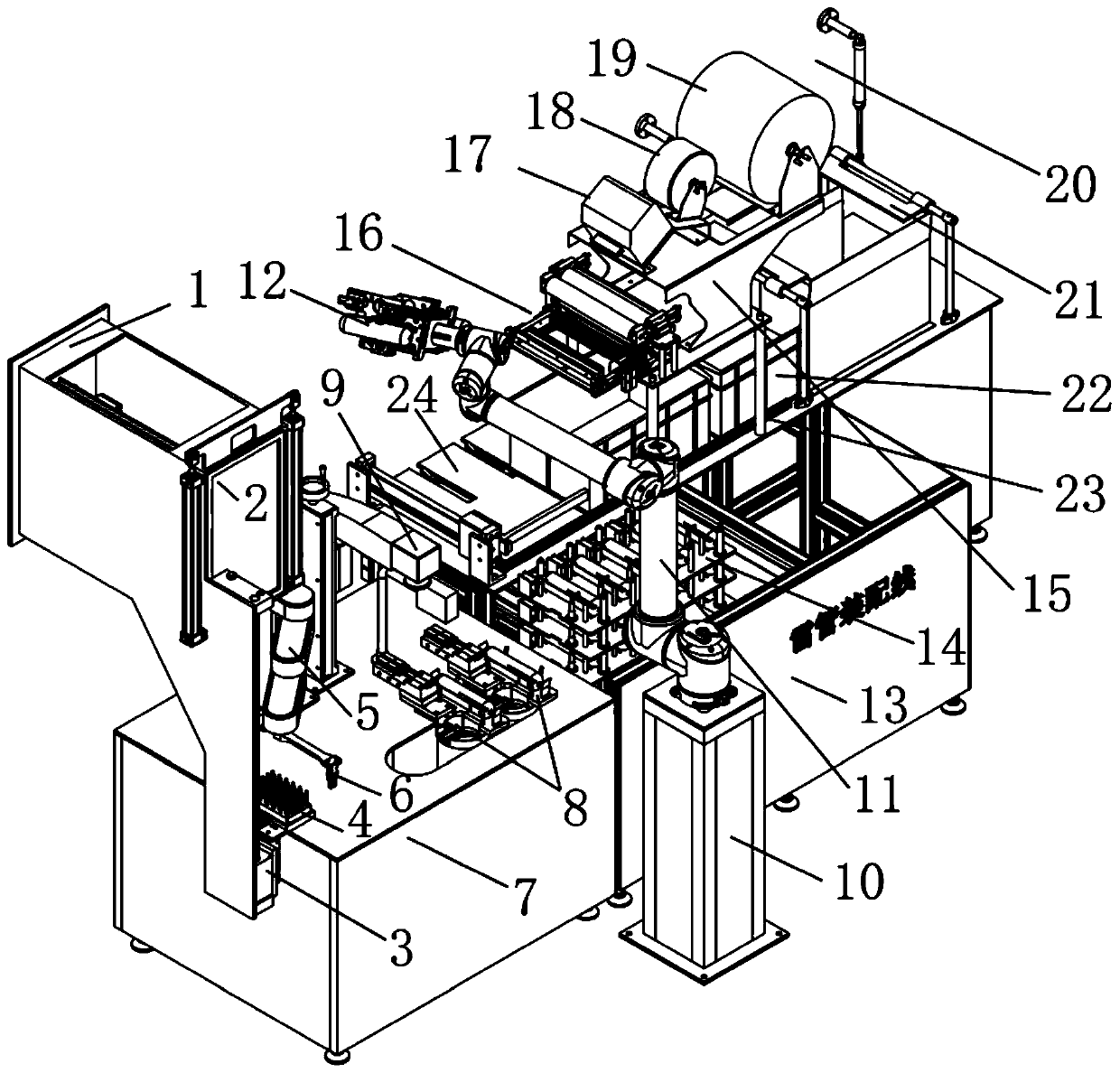

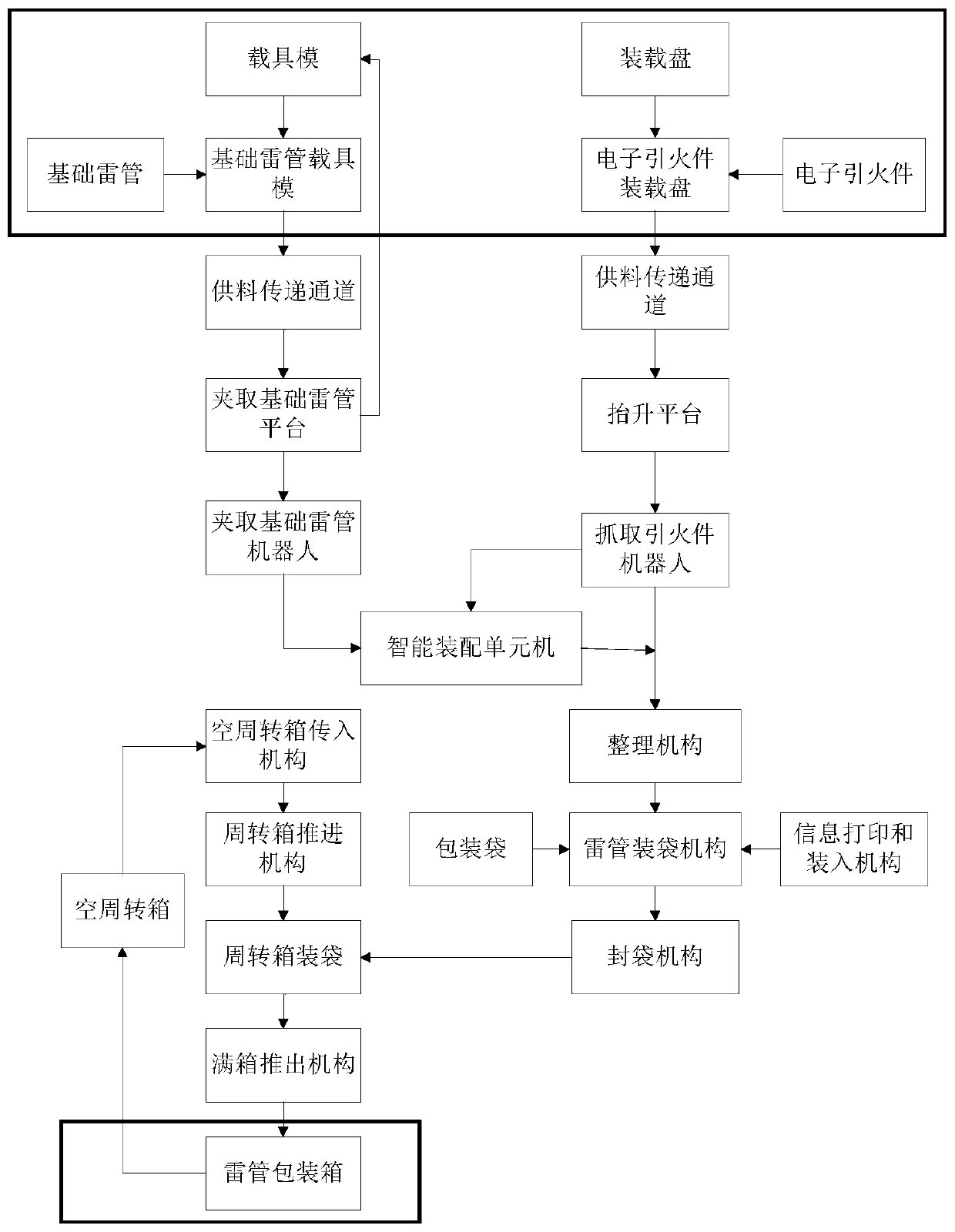

[0032] This embodiment provides an electronic detonator assembly production unit line. The assembly production unit line includes a basic detonator feeding module, an electronic ignition part feeding module 13, a basic detonator gripping robot 5, a grabbing ignition part robot 11, and a fully automatic assembly The unit machine 7, the intermediate packaging machine 15 and the finished product turnover box transfer module. The assembly production unit line is located in an explosion-proof room, and the explosion-proof room is composed of steel plates with a thickness between 10 mm and 20 mm connected by welding or bolts.

[0033] Such as figure 1 As shown, the basic detonator feeding module is arranged on the upper left side of the fully automatic assembly unit machine 7, and the basic detonator feeding module includes the basic detonator carrier mold feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com