Novel positioning rib detection device

A detection device and positioning rib technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of poor device adjustment effect, etc., and achieve the effect of efficient detection, flexible lifting, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

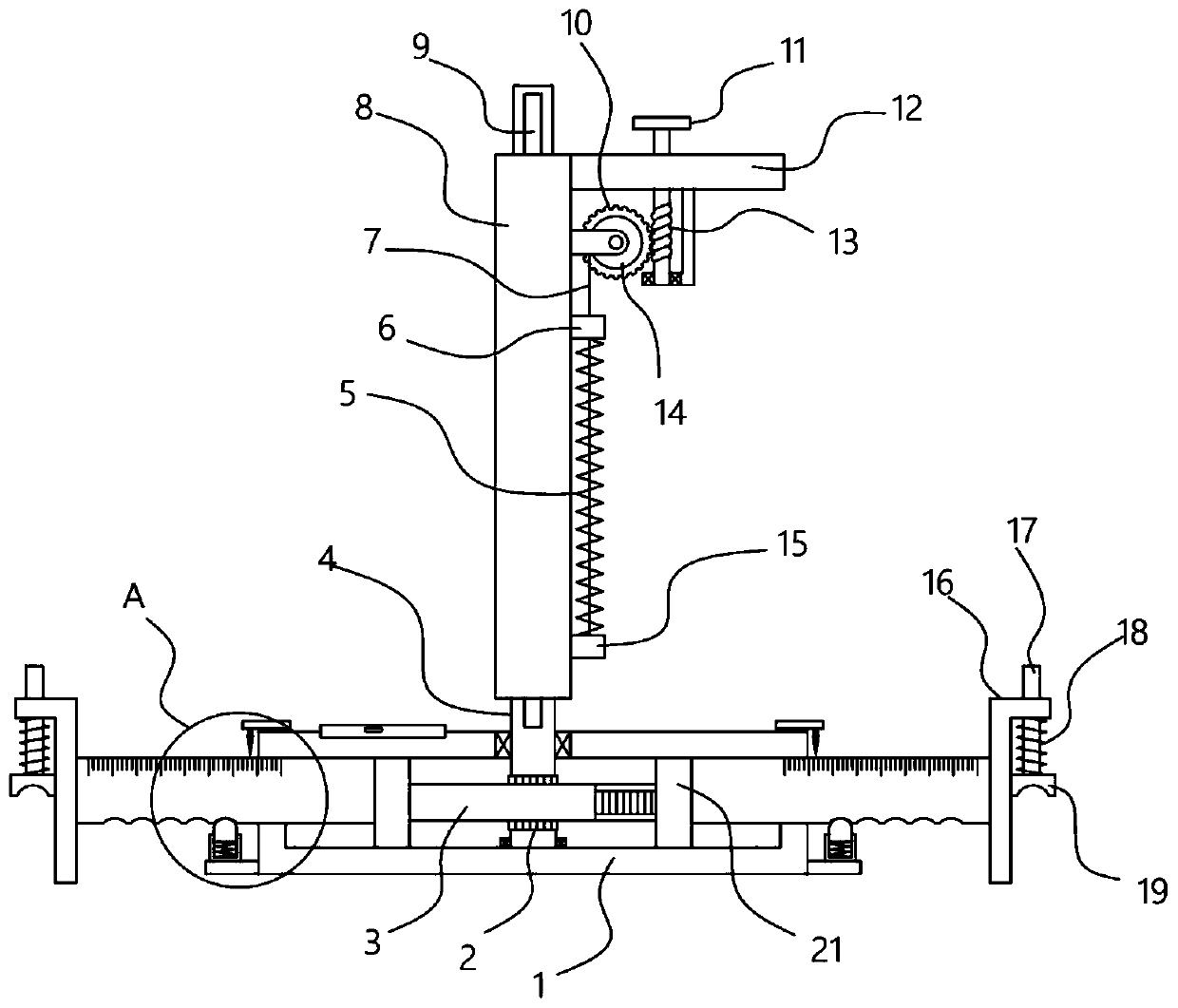

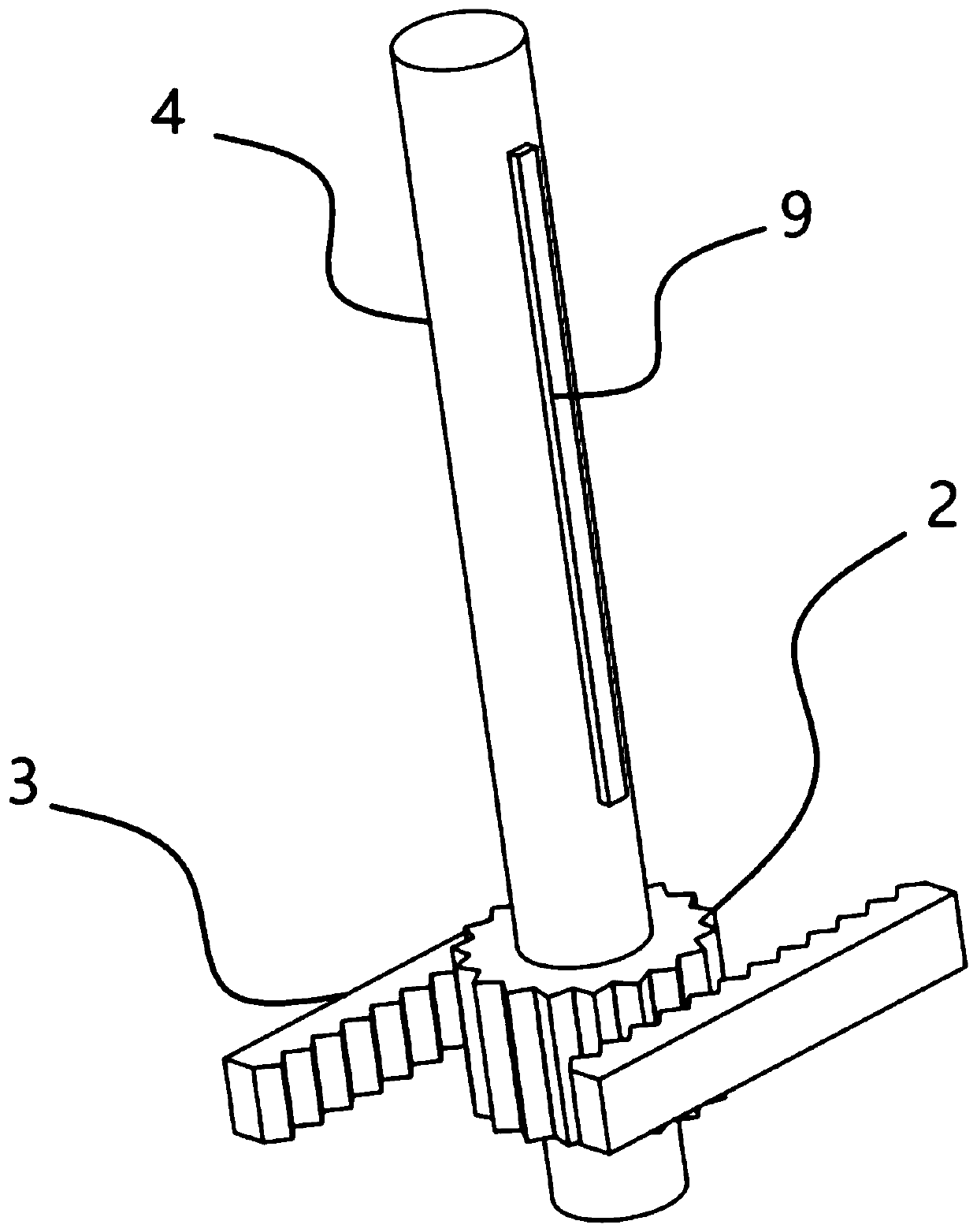

[0021] see Figure 1-3 , a new type of positioning rib detection device, including a transmission box 1, an adjustment sleeve 8 is vertically fixed on the transmission box 1, two symmetrically arranged telescopic rods 23 are slidably installed in the transmission case 1, and the ends of the telescopic rods 23 are fixed and useful For the clamping mechanism for clamping the positioning ribs, the transmission box 1 is provided with a telescopic mechanism for driving the telescopic rod 23 to slide. The adjustment sleeve 8 is sleeved with an adjustment sleeve 8, and the inner wall of the adjustment sleeve 8 is slidably embedded with a transmission clip 9 fixed on the side wall of the adjustment rotation rod 4. The adjustment sleeve 8 is fixed with a grip rod 12 , The grip rod 12 is provided with a lifting mechanism for driving the adjustment sleeve 8 to slide vertically relative to the adjustment rotating rod 4 .

[0022] The clamping mechanism set in this device is used to clamp...

Embodiment 2

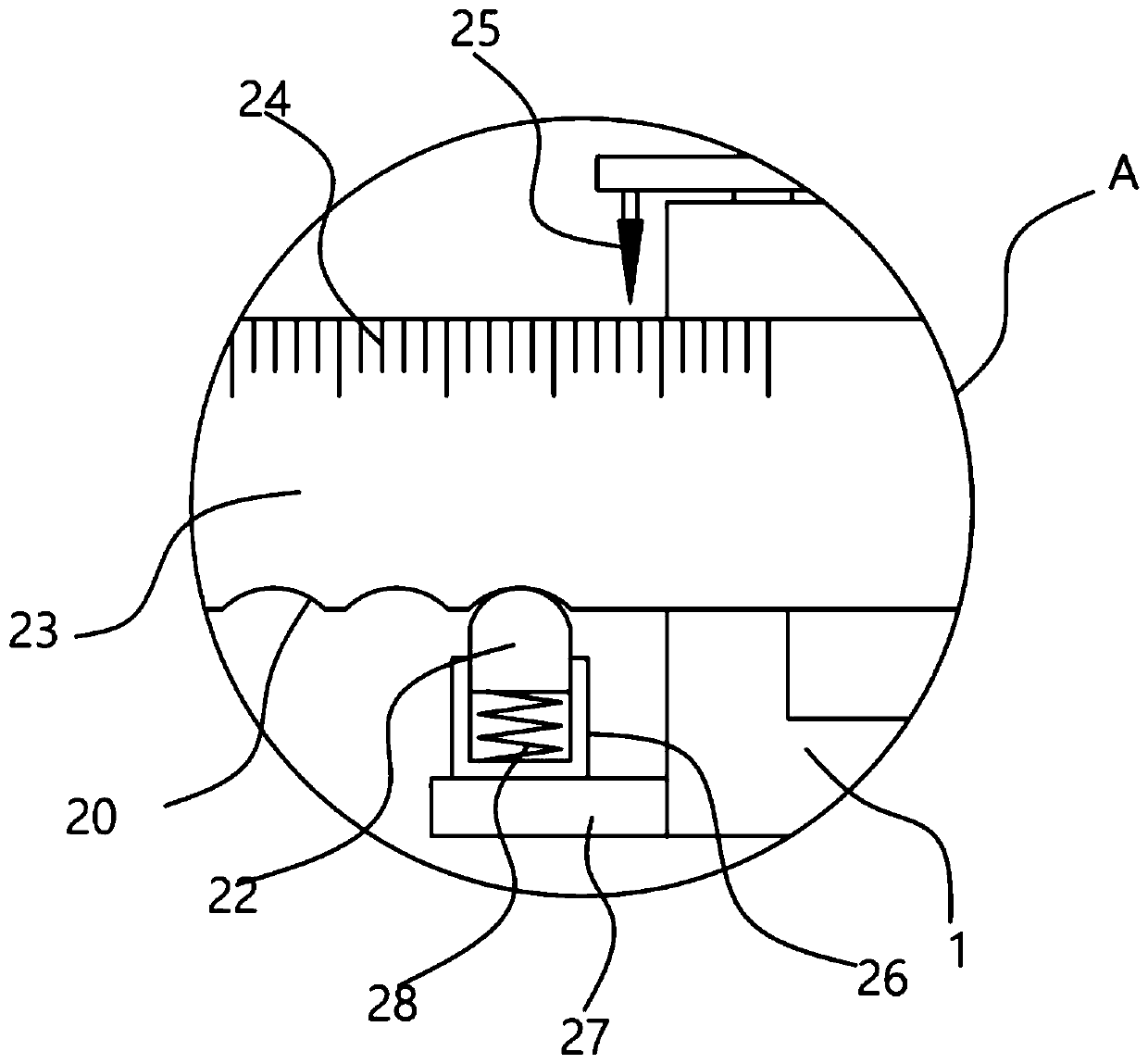

[0028] On the basis of Embodiment 1, in addition, in addition, the clamping mechanism of the device includes an adjustment frame 16 fixed at the end of the telescopic rod 23, the adjustment frame 16 vertically slides through the guide column 17, and the bottom of the guide column 17 is fixed with an arc Block 19, the spring 18 that is sleeved on the guide post 17 is fixed between the arc block 19 and the adjustment frame 16, and the arc block 19 that is provided can clamp the positioning rib vertically downward, and press down under the elastic action of the spring 18. Tightly on the positioning rib, the arc groove provided at the bottom of the arc block 19 can play a limiting effect on the positioning rib.

[0029] In order to improve the adjustability of the device, the device is also provided with a lifting mechanism, including a fixed block 15 fixed on the side wall of the adjustment sleeve 8, and the side wall of the transmission clip 9 is fixed with a limiter that is vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com