Diesel heavy truck oil tank oil quantity online measuring system and method

A measurement system and measurement method technology, applied in the direction of volume measurement instrument/method, container/cavity capacity measurement, measurement capacity, etc. The effect of signal fluctuations, improving accuracy, eliminating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

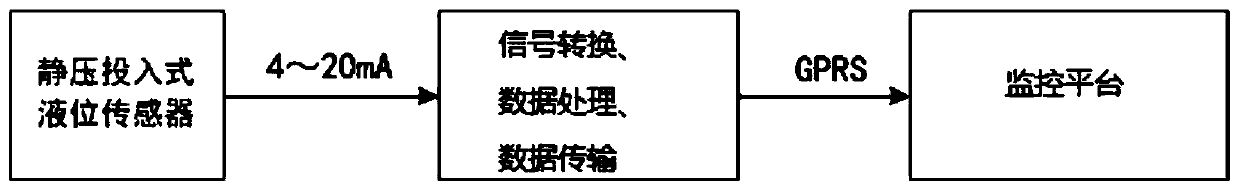

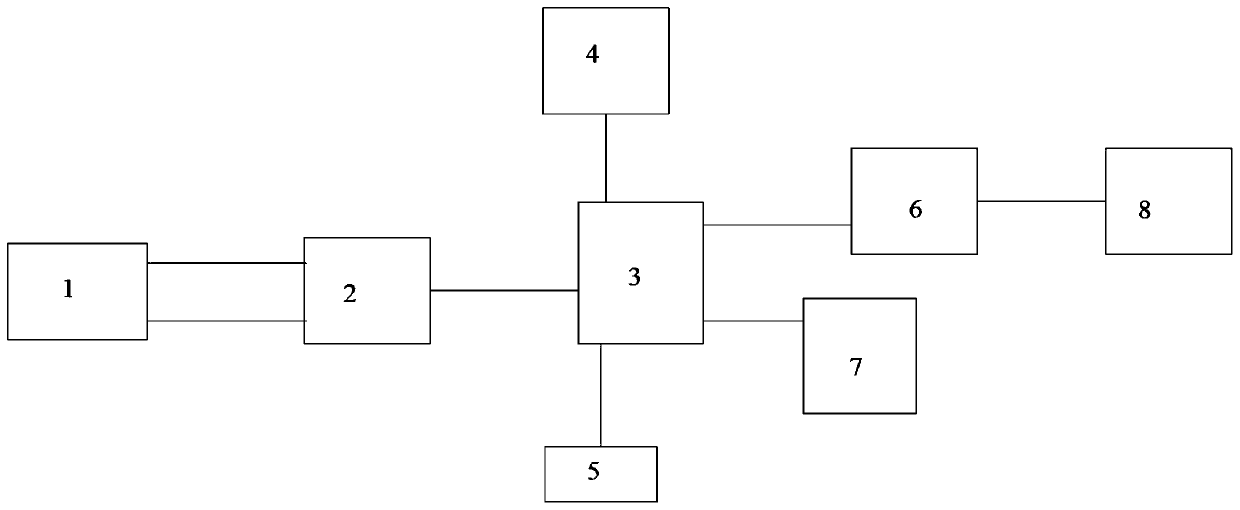

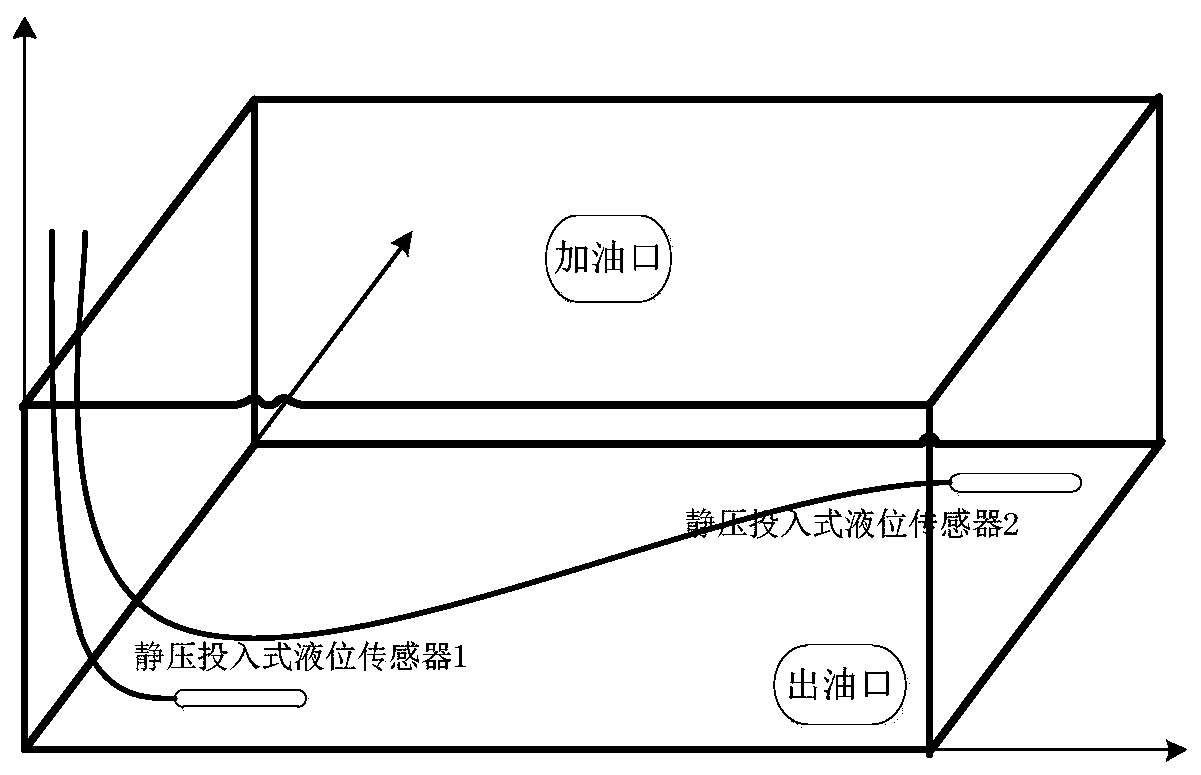

[0047] Such as figure 1 and figure 2 , Figure 17 As shown, in the online measurement system for the fuel volume of a diesel heavy truck fuel tank, two liquid level sensors 9 are arranged in the fuel tank 1, and the two liquid level sensors 9 are sequentially connected to the signal conversion module 2, the data processing module 3, the data transmission module 6, and the monitoring platform 8, Data processing module 3 is connected with display module 7, real-time clock module 5, alarm device 4 respectively;

[0048] The RAM of the data processing module 3 is provided with a liquid level data buffer, and the liquid level is calculated using the data in the liquid level data buffer.

[0049] The real-time clock module generates date and time, and the data processing module 3 combines time information and fuel quantity information to record, store or display the fuel quantity at a point in time.

[0050] The liquid level sensor 9 is a static pressure input liquid level senso...

Embodiment 2

[0056] Such as Figure 15 and Figure 16 , Figure 17 As shown, the online oil quantity measurement method process is:

[0057] The liquid level sensor 9 transmits the current signal to the signal conversion module 2, and the signal conversion module 2 converts the current signal into a voltage signal;

[0058] The signal conversion module 2 converts the voltage signal into a digital signal and inputs it into the data processing module 3;

[0059] The real-time clock module 5 transmits the signal to the data processing module 3, and the data processing module 3 stores the obtained fuel quantity signal into the memory 13;

[0060] The data processing module 3 calculates the liquid level by means of weighted average filtering, and then calculates the existing oil quantity according to the specification of the fuel tank and the oil quantity information displayed by the display module;

[0061] The data processing module transmits the oil quantity signal to the display module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com