Method for determining multi-point production cigarette standard samples by membership function

A membership function and standard sample technology, applied in the field of tobacco production, can solve problems such as insufficient key quality indicators, emphasis on sensory quality scores of samples, and no quantitative scoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

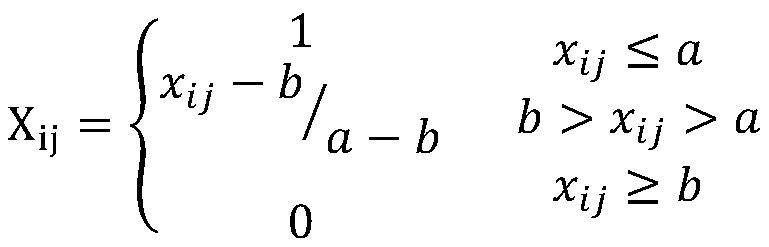

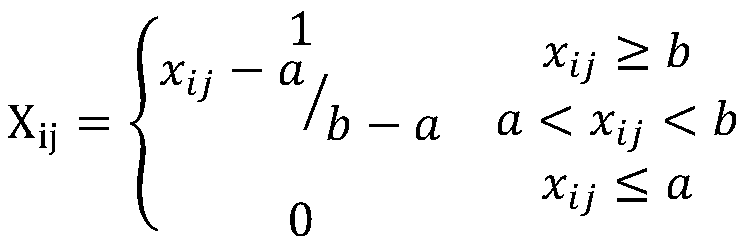

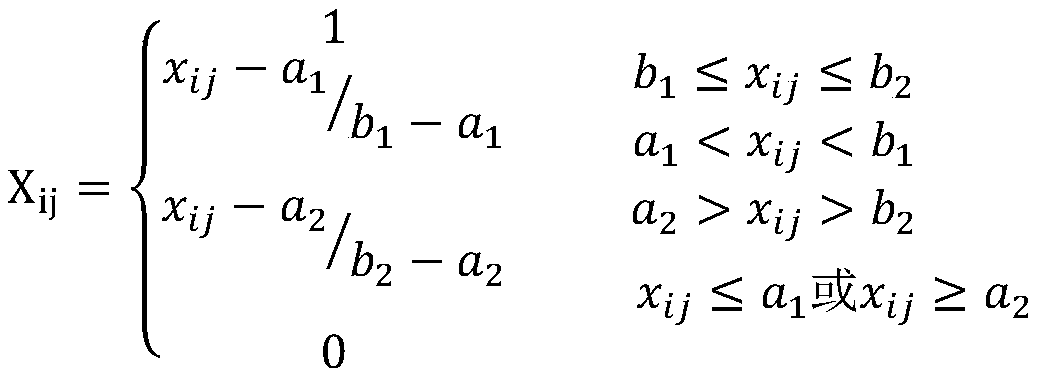

Method used

Image

Examples

Embodiment 1

[0048] Select 6 production sites with the largest output of cigarettes of a certain brand specification, and evaluate the sensory quality of the cigarette samples of the 6 production sites according to YC / T 138-1998 Tobacco and Tobacco Products Sensory Evaluation and Smoking Method. At the same time, according to the standard and literature methods, the physical appearance of cigarettes, the percentage of turning heads, the percentage of stems, the amount of tar in mg, the amount of carbon monoxide in mg, and the amount of nicotine in mg are detected.

[0049] Among them, the quality score of the physical appearance index is determined as follows: the appearance index of cigarettes includes 13 items (3, 2, and 8 items for class A, class B, and class C defects respectively), and the physical index of cigarettes includes 10 items (classes A, B, and C). Class and C defects are 1 item, 2 items, and 7 items respectively). After summarizing the deduction points for various quality d...

Embodiment 2

[0088] Select a slim cigarette processed by the 4 production sites with the largest brand specification output, and evaluate the sensory quality of the cigarette samples produced by the 4 production sites according to YC / T 138-1998 Tobacco and Tobacco Products Sensory Evaluation and Smoking Method. At the same time, according to the standard and literature methods, the physical appearance of cigarettes, the percentage of turning heads, the percentage of stems, the amount of tar in mg, the amount of carbon monoxide in mg, and the amount of nicotine in mg are detected.

[0089] Among them, the appearance indicators of cigarettes include 13 items (3 items, 2 items, and 8 items for class A, class B, and class C defects, respectively), and the physical indicators of cigarettes include 10 items (10 items for class A, class B, and class C defects, respectively). items, 2 items, 7 items). After summarizing the various quality deduction points for physical indicators and appearance ind...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap