Sealed high-low voltage power distribution cabinet

A technology of high and low voltage power distribution cabinets, which is applied in the field of sealed high and low voltage power distribution cabinets, which can solve the problems of poor sealability of sealing rings, poor product shaping ability, high electrostatic current, etc., achieve good waterproof sealing and increase dustproof effect, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

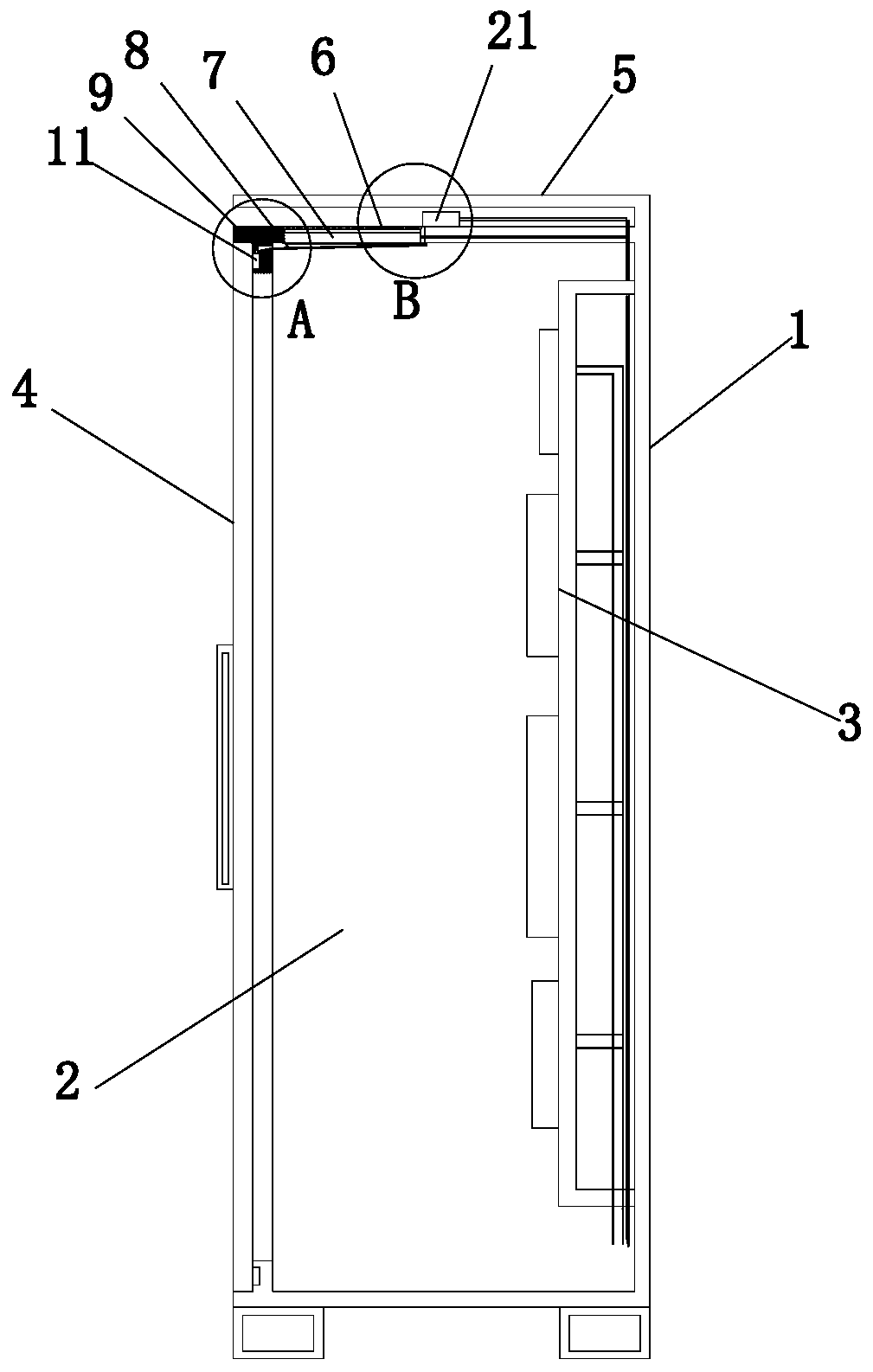

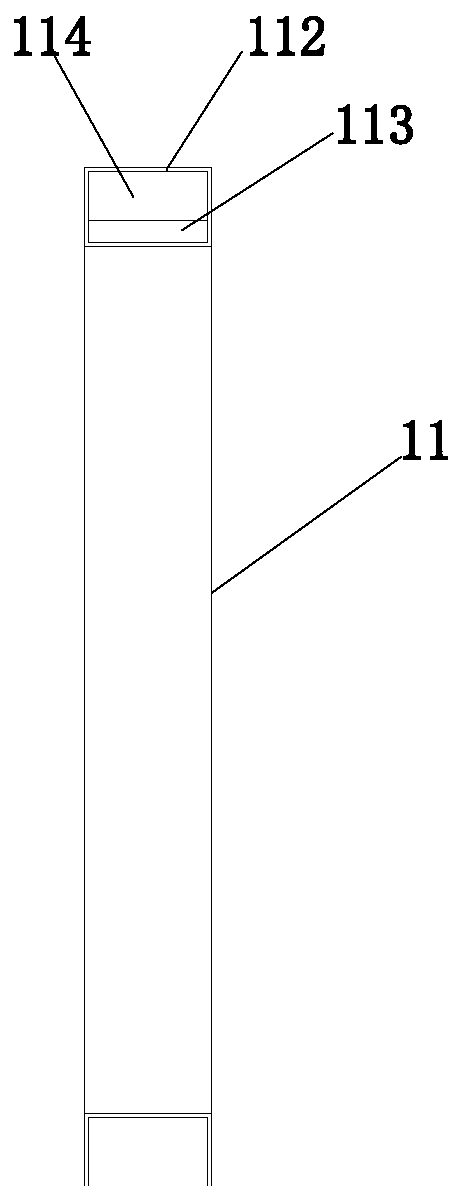

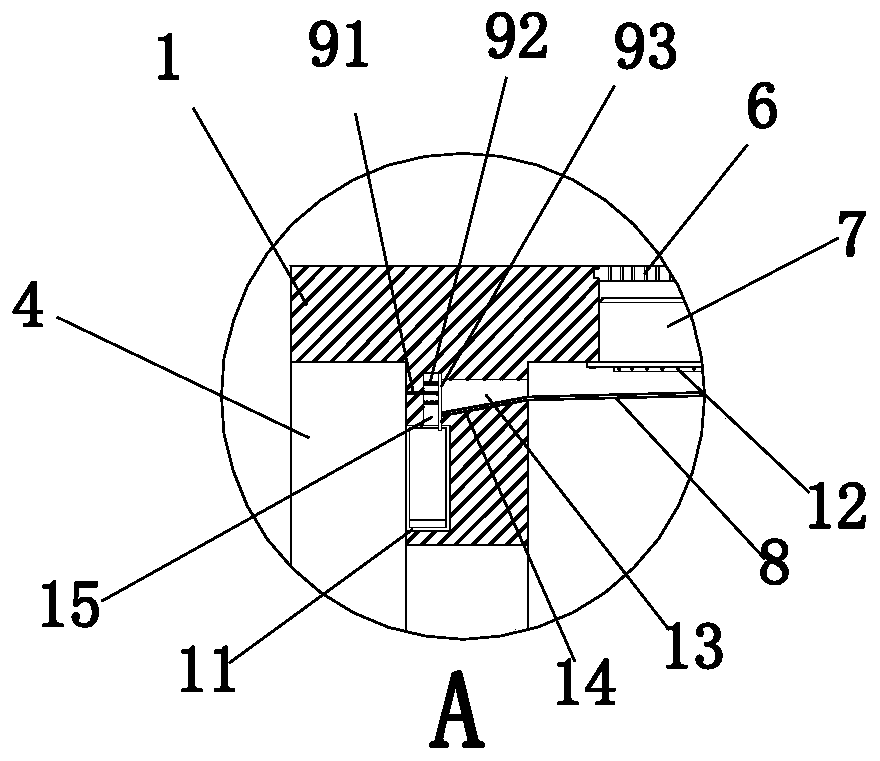

[0025] Such as figure 1 and Figure 4 As shown, the sealed high and low voltage power distribution cabinet includes a cabinet body 1, and a heat dissipation fan 7 is installed on the top of the cabinet body 1. The heat dissipation fan 7 draws the external air into the installation cavity 2 inside the cabinet body 1, and the The exhaust port at the bottom of the body 1 is discharged. The cabinet body 1 is provided with a cabinet door 4. A hollow silicone sealing ring 11 is embedded on the side of the cabinet body 1 facing the cabinet door 4. When the cabinet door 4 is closed, the cabinet door 4 and the slightly convex The silicone sealing ring 11 contacts the seal;

[0026] A filter screen 6 is installed on the top air inlet end of the cooling fan 7, and an electrostatic net 12 is installed on the air outlet end of the cooling fan 7, and an electrostatic generator 21 is installed on the top outer side of the cabinet body 1, and the electrostatic bar of the electrostatic genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com